Efficient continuous water atomizing process for producing steel powder

A technology of iron and steel powder and process method, which is applied in the field of powder metallurgy, can solve problems such as bulk density and particle size distribution fluctuations, and achieve the effects of improving quality, reducing tapping temperature, and improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

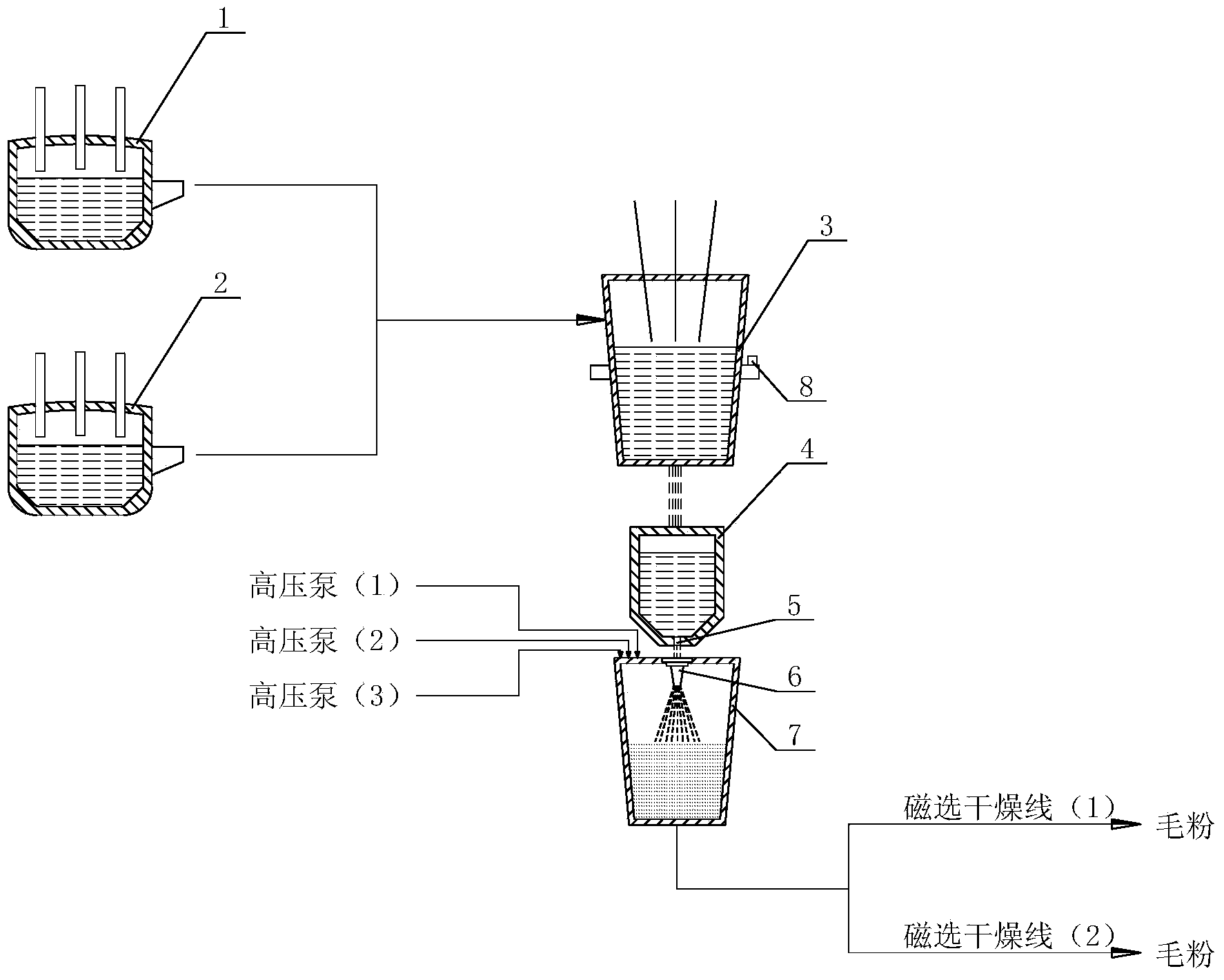

[0034] See figure 1 , is a specific embodiment of a high-efficiency continuous water atomization process for producing steel powder in the present invention. The system is equipped with two electric arc furnaces, one 5t electric arc furnace 1, one 10t electric arc furnace 2, and the capacity of the intermediate heating device 3 The molten steel smelted by the electric arc furnace 1 and 2 is continuously poured into the intermediate heating device 3; after the atomization starts, the molten steel flows out through the leak hole 5 of the tundish 4, and the high-pressure water pumped out by the high-pressure pump sprays the molten steel in the mist The atomizer 7 is broken into tiny liquid droplets, which are sprayed out from the atomizing nozzle. This embodiment is equipped with three high-pressure pumps, which are respectively high-pressure pump (1), high-pressure pump (2) and high-pressure pump (3), with two working and one standby, or two standby and one working. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com