Spherical ferrate having hollow structure and preparation method thereof

A hollow structure, ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve problems that restrict the performance of ferrite materials such as lithium-ion battery applications, and achieve uniform particle distribution and preparation parameters Ease of control and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

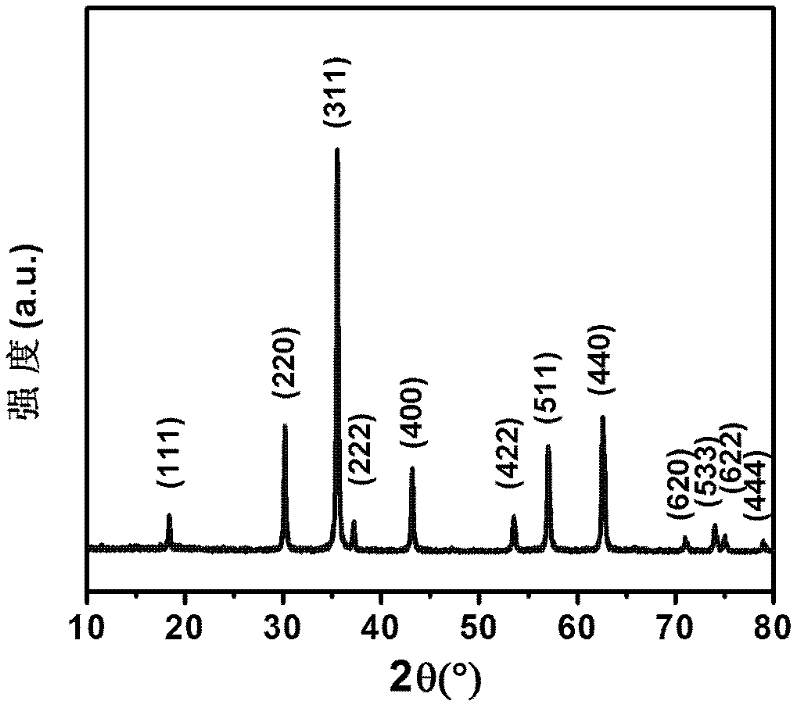

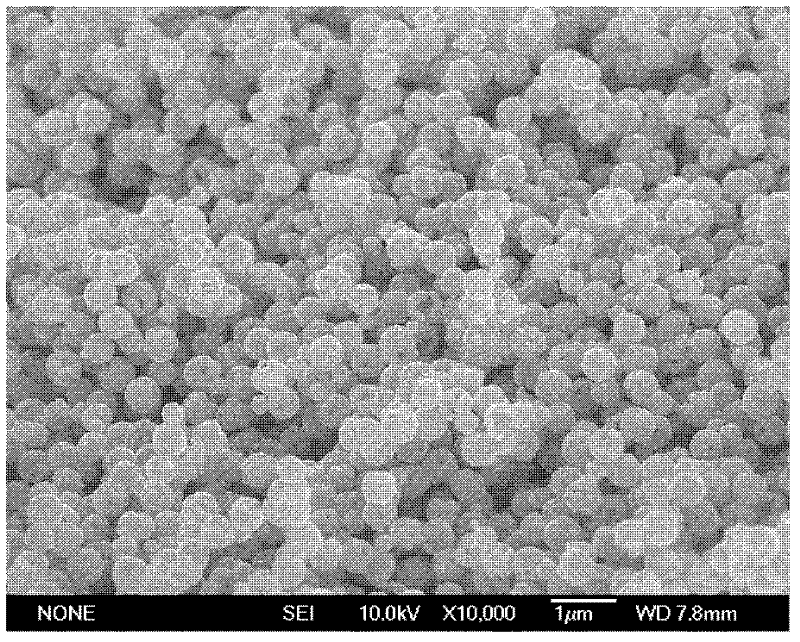

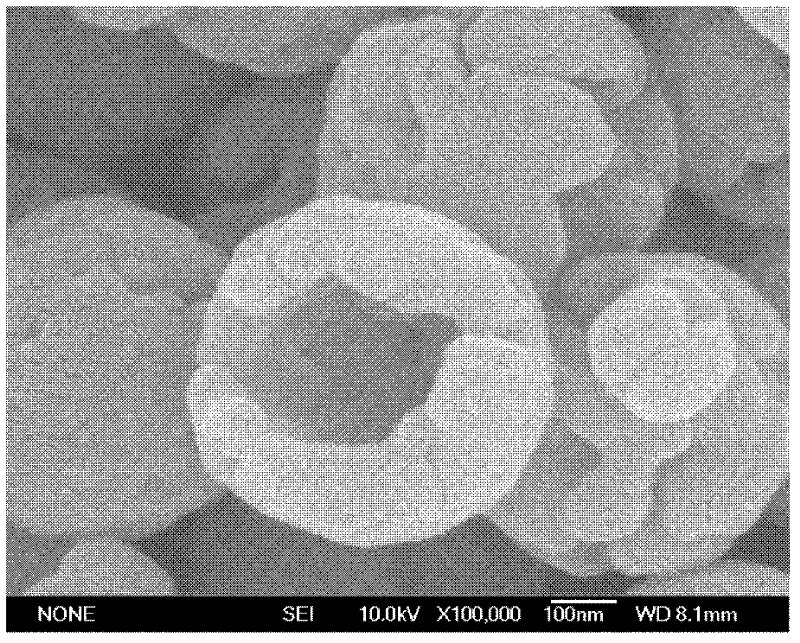

[0030] Take 10mmol of ferric chloride and 5mmol of zinc chloride, add them to 80mL of ethylene glycol, dissolve to obtain a clear solution, then slowly add 2ml of polyethylene glycol dropwise under vigorous stirring, and finally add 90mmol of urea, and continue stirring for 20min . The obtained solution is poured into a polytetrafluoroethylene liner with a capacity of 100 ml to a filling degree of 80%. After sealing, put it into a stainless steel reaction kettle, place it in an oven and react at 200°C for 24h. After the reaction kettle was lowered to room temperature, the product was collected, and the product was centrifugally washed several times with ethanol and distilled water. Finally, the washed product was placed in a vacuum oven and dried at 60°C for 12 hours to obtain zinc ferrite powder. That figure 1 The X-ray diffraction spectrum of the self-assembled zinc ferrite hollow microsphere powder prepared in this example can be seen from the spectrum that its phase is z...

Embodiment 2

[0032]Take 10mmol of ferric chloride and 5mmol of cobalt chloride as starting materials, add them into 80mL of ethylene glycol, dissolve to obtain a clear solution, then slowly add 2ml of PEG-600 dropwise under vigorous stirring, and finally add 90mmol of urea, Stirring was continued for 20 min. The obtained solution is poured into a polytetrafluoroethylene liner with a capacity of 100 ml to a filling degree of 50%. After sealing, put it into a stainless steel reaction kettle, place it in an oven and react at 200°C for 24h. After the reaction kettle was lowered to room temperature, the product was collected, and the product was centrifugally washed several times with ethanol and distilled water. Finally, the washed product was placed in a vacuum oven and dried at 60°C for 12 hours to obtain cobalt ferrite powder. The results of X-ray diffraction pattern show that its phase is cobalt ferrite with cubic spinel structure. The scanning electron microscope observation results sho...

Embodiment 3

[0034] Take 4mmol of iron nitrate and 2mmol of nickel nitrate as starting materials, add them into 80mL of ethylene glycol, dissolve to obtain a clear solution, then slowly add 2ml of PEG-600 dropwise under vigorous stirring, and finally add 8mmol of urea, continue stirring 20min. The obtained solution is poured into a polytetrafluoroethylene liner with a capacity of 100 ml to a filling degree of 80%. After sealing, put it into a stainless steel reaction kettle, place it in an oven and react at 240°C for 6h. After the reaction kettle was lowered to room temperature, the product was collected, washed several times with ethanol and distilled water, and finally the washed product was put into a vacuum oven and dried at 60° C. for 12 hours. Finally, the self-assembled nickel ferrite hollow microsphere powder is obtained. The results of X-ray diffraction pattern show that its phase is nickel ferrite with cubic spinel structure. The scanning electron microscope observation result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com