Method for preparing high-quality bismuth ferrite ferroelectric photovoltaic films by magnetron sputtering

A magnetron sputtering, ferroelectric photovoltaic technology, applied in sputtering coating, ion implantation coating, metal material coating process and other directions, can solve the problem of low equipment condition efficiency, reduce leakage current, obvious photovoltaic effect , The effect of strong controllability of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention and the beneficial effects that can be obtained are described in detail below using examples.

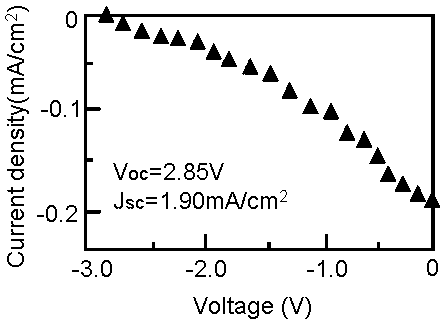

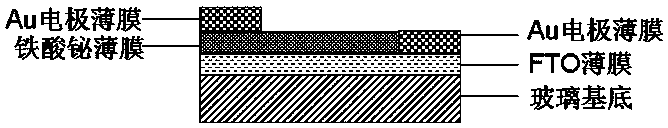

[0022] (1) The bismuth ferrite (BFO) ceramic target doped with dysprosium (Dy) is used as the sputtering target, and the relative atomic percentage content [Dy / (Dy+Bi)]×100%=10%, the sputtering target Fix it on the RF sputtering target platform; use FTO / glass as the substrate, clean the substrate with propanol, absolute ethanol, and deionized water in an ultrasonic cleaner for 10 minutes, then blow dry with nitrogen and immediately put it into a vacuum chamber The chamber is fixed on the sample stage, and the distance between the sample stage and the target stage is adjusted to 120mm;

[0023] (2) Use a mechanical pump and a molecular pump to evacuate the vacuum chamber to 5.0×10 -4 Pa, then open the throttle valve of the exhaust system, according to the gas flow ratio O 2 : Ar=1:5 into O 2 and Ar gas; set the gas flow, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com