Flexible solar blind ultraviolet detector based on TiO2/Ga2O3 nano-phase junction and preparation method of flexible solar blind ultraviolet detector

A technology of ultraviolet detector and nano phase, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problems of limiting the application range of devices, weak bonding of substrates, and difficulty in making electrodes. , achieve the effect of stable solar blindness, excellent chemical and thermal stability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

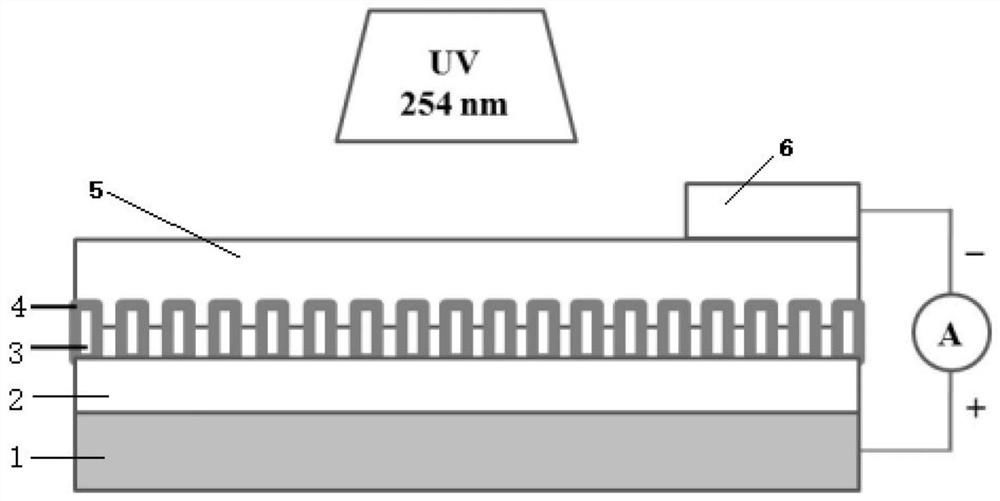

[0035] Based on TiO 2 / Ga 2 o 3 The preparation method of the flexible sun-blind ultraviolet detector of nanometer junction, comprises the following steps:

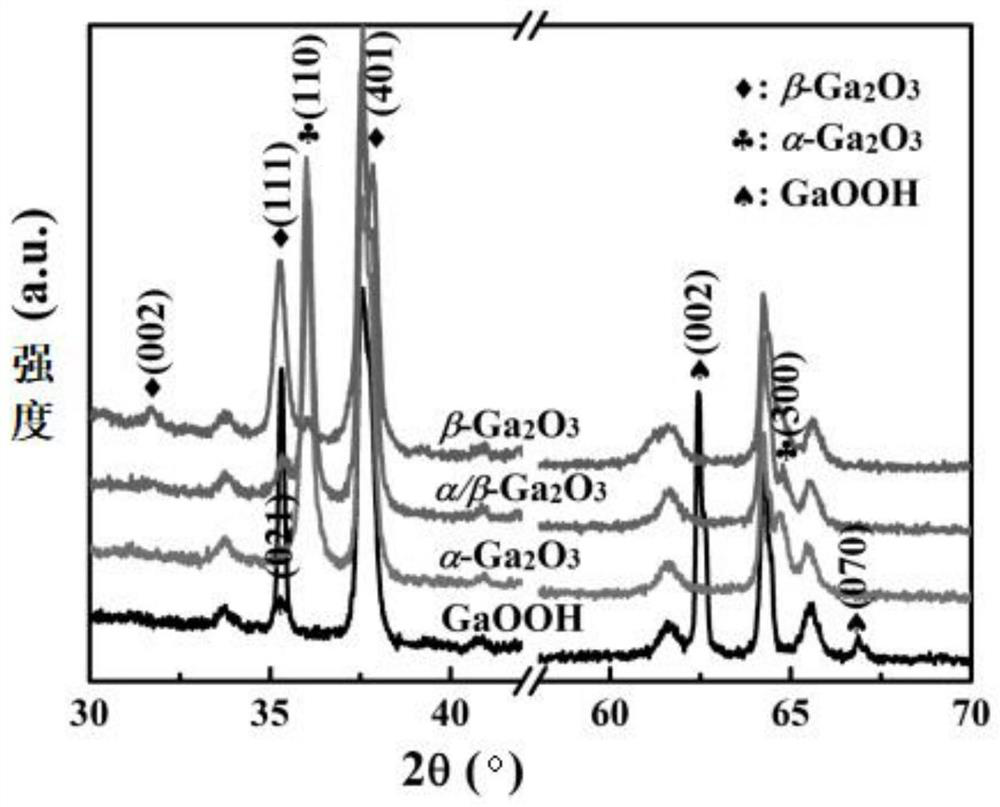

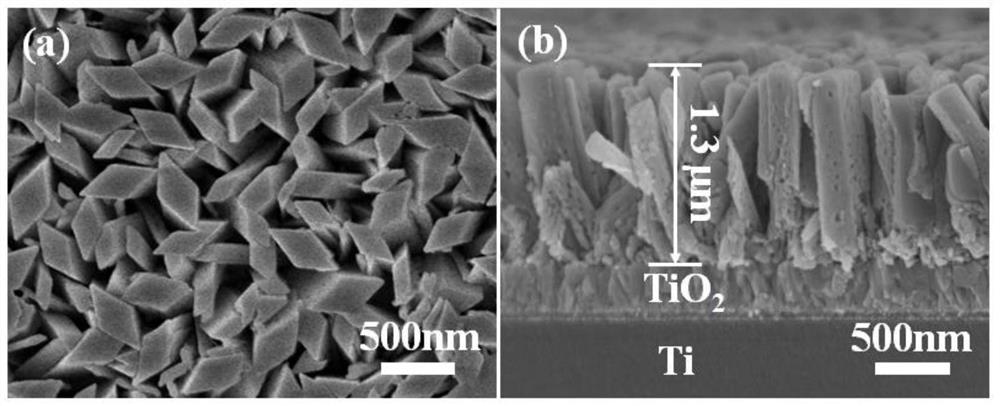

[0036] (1) Soak the flexible titanium sheet substrate in acetone, ethanol, and deionized water for 10 minutes, then rinse it with deionized water after taking it out, and dry it with dry nitrogen; put the cleaned metal titanium sheet into oxygen In the plasma, the surface of metal titanium is oxidized to form a dense layer of TiO 2 layer, namely to obtain TiO 2 / Ti sheet substrate; (2) get 30mL concentration and be that the gallium isopropoxide solution of 0.5mol / L is placed in the reactor liner, then the TiO of step (1) gained 2 / Ti sheet substrate is leaned against the reactor liner and immersed in gallium isopropoxide solution, in which TiO 2 This side is facing down (that is, toward the side of the reactor liner leaning against); (3) Transfer the reactor to an oven, react at 150°C for 6h, then take out the sample...

Embodiment 2

[0046] Steps (1), (4) and (5) are all the same as in Example 1. The concentration of gallium isopropoxide solution in step (2) is 0.5mol / L. In step (3), react at 150°C for 7h, hydrothermally grow gallium oxyhydroxide, and then transfer GaOOH to a high-temperature furnace for annealing, first at 400°C Annealed for 1.5 hours to obtain TiO 2 / α-Ga 2 o 3 nanopillar array, and then the high-temperature furnace was rapidly heated to 700 ° C, and continued annealing for 20 minutes to obtain TiO 2 / α / β-Ga 2 o 3 Junction nanopillar arrays. The resulting TiO 2 / α / β-Ga 2 o 3 Crystal structure, chemical composition and TiO-based 2 / Ga 2 o 3 The photoelectric properties of the flexible solar-blind ultraviolet detectors with nanostructures are similar to those of Example 1.

Embodiment 3

[0048] Steps (1), (4) and (5) are all the same as in Example 1. The concentration of gallium isopropoxide solution in step (2) is 1.0 mol / L. In step (3), react at 150°C for 8 hours to hydrothermally grow gallium oxyhydroxide, then transfer GaOOH to a high-temperature furnace for annealing, first at 500°C Annealed for 2.0 hours to obtain TiO 2 / α-Ga 2 o 3 nanopillar array, and then the high-temperature furnace was rapidly heated to 800 ° C, and continued annealing for 10 minutes to obtain TiO 2 / α / β-Ga 2 o 3 Junction nanopillar arrays. The resulting TiO 2 / α / β-Ga 2 o 3 Crystal structure, chemical composition and TiO-based 2 / Ga 2 o 3 The photoelectric properties of the flexible solar-blind ultraviolet detectors with nanostructures are similar to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com