Preparation method of uniform-dimension polymer nano microspheres

A technology of nano-microspheres and polymers is applied in the field of preparation of polymer nano-microspheres of uniform size, and achieves the effects of low cost, high yield and highly controllable preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Place 1 gram of polystyrene and polymethyl methacrylate copolymer (molecular weight is 70,000) with a weight ratio of 1:0.3 in a 50 ml glass flask equipped with a reflux device, and then add 30 g propionic acid;

[0018] 2) Heat the liquid in the flask to 110°C with an oil bath and keep it for 10 hours;

[0019] 3) Stop heating and cool to room temperature to obtain polymer microspheres dispersed in propionic acid.

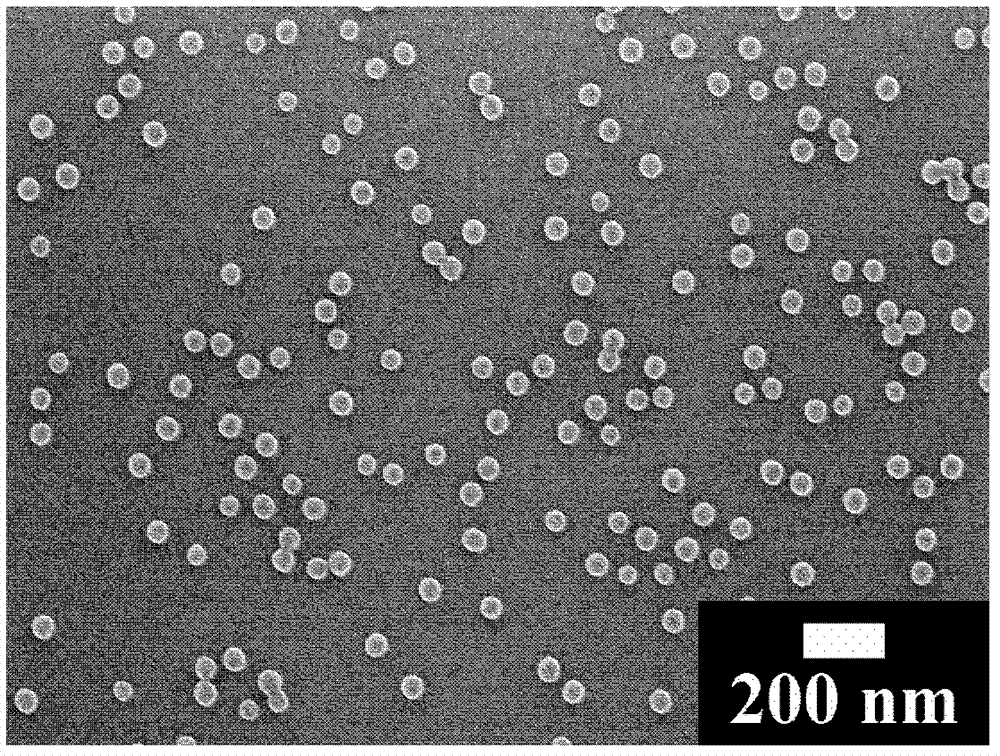

[0020] The scanning electron microscope (SEM) image of the obtained polymer microspheres is shown in figure 1 Shown; The diameter of the microspheres measured from the SEM image is 55 nanometers; and the size is uniform.

Embodiment 2

[0022] In Example 2, compared to Example 1 step 1), the amount of polymer used was increased to increase the yield, and the dissolution temperature was increased to reduce the time required for dissolution.

[0023] 1) 5 grams of polystyrene and polymethyl methacrylate with a weight ratio of 1: 0.3 (molecular weight of a copolymer of 70,000 Daltons) are placed in a 50-ml glass flask equipped with a reflux device, and then poured into the flask Add 30 grams of propionic acid;

[0024] 2) Heat the liquid in the flask to 150°C with an oil bath and keep it for 2 hours;

[0025] 3) Stop heating and cool to room temperature to obtain polymer microspheres dispersed in propionic acid.

[0026] Observing the obtained polymer microspheres with a scanning electron microscope, the diameter of the microspheres measured from the SEM image is also 55 nanometers, and the size is uniform.

Embodiment 3

[0028] Compared with Example 1, Example 2 changed the type, molecular weight, weight ratio of chain segments, and the weight ratio of copolymer to solvent to obtain polymer microspheres with different chemical compositions and particle sizes.

[0029] 1) 2 grams of polystyrene and poly(4-vinylpyridine) (molecular weight 20,000 Daltons) in a weight ratio of 1:0.2 are placed in a 25 ml glass flask equipped with a reflux device, and then Add 10 grams of propionic acid in the flask;

[0030] 2) Stir and heat the liquid in the flask to 30°C with an oil bath, and keep it for 10 minutes;

[0031] 3) Stop heating and cool to room temperature to obtain polymer microspheres dispersed in propionic acid.

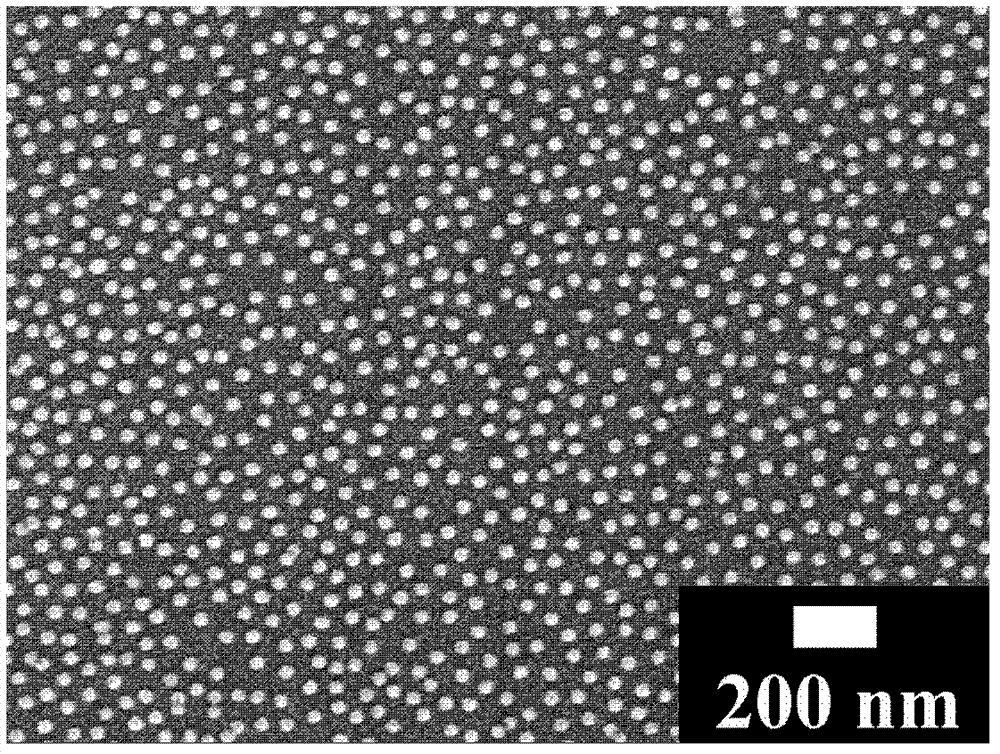

[0032] Scanning electron microscope images of the resulting polymer microspheres are shown in figure 2 Shown; The diameter of the microspheres measured from the SEM image is 30 nanometers; and the size is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com