Modified spinel type lithium battery cathode material and preparation method thereof

A spinel-type, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as restricting competitive advantages and wide application, unsatisfactory rate performance, and low specific capacity of spinel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

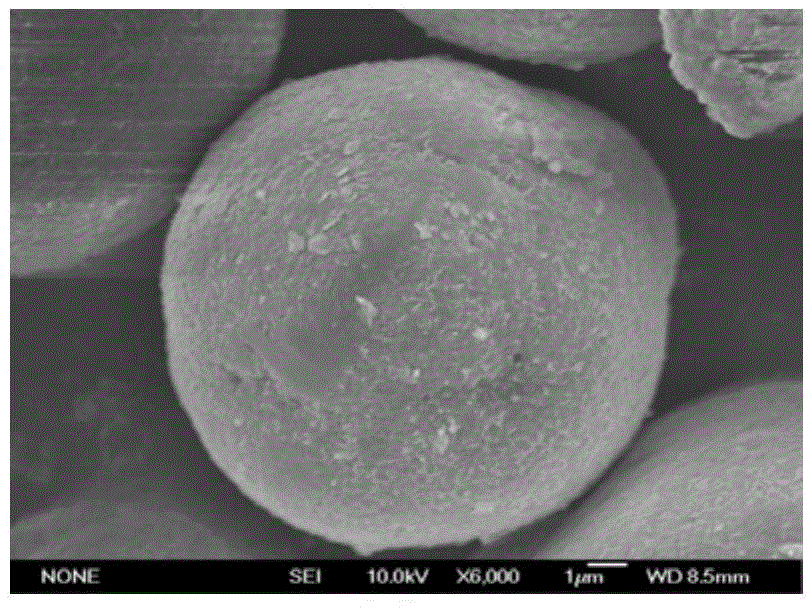

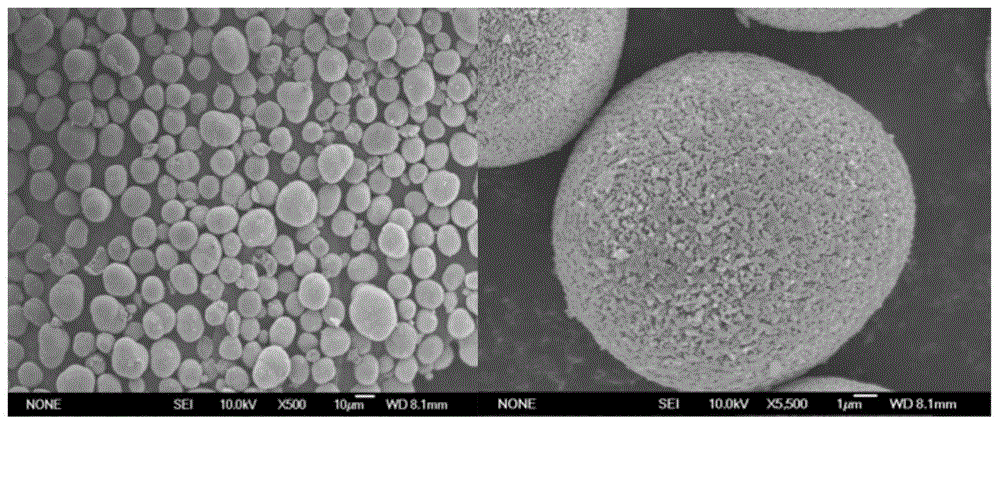

[0032] A modified spinel-type lithium-ion battery positive electrode material is a layered composite material with a core-shell structure composed of a lithium-rich phase material as a shell material and a spinel phase material as a core material, and its chemical formula is 0.1[ Li 1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.9[Li 0.5 Ni 0.25 mn 0.75 o 2 ].

[0033] The preparation method of the modified spinel type lithium ion battery positive electrode material, the steps are as follows:

[0034] 1) NiSO 4 ·6H 2 O and MnSO 4 ·H 2 O mixed and dissolved in deionized water to obtain a mixed salt solution, NiSO in the mixed salt solution 4 ·6H 2 O and MnSO 4 ·H 2 The concentration of O is 2.5mol / L, and the molar ratio of Ni to Mn is 0.25:0.75;

[0035] 2) In the above-mentioned mixed salt solution, under stirring conditions, add a concentration of ammonia solution of 0.25mol / L and a mixed solution of sodium carbonate solution of 2.5mol / L, and the mol ratio of ammonia and sodiu...

Embodiment 2

[0043] A preparation method of a modified spinel type lithium ion battery positive electrode material, the chemical formula of the lithium ion battery positive electrode material is 0.1[Li 1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.9[Li 0.5 Ni 0.25 mn 0.75 o 2 ], the preparation steps are basically the same as in Example 1, except that the roasting time in step 3) is 15h.

Embodiment 3

[0045] A preparation method of a modified spinel type lithium ion battery positive electrode material, the chemical formula of the lithium ion battery positive electrode material is 0.1[Li 1.5 Ni 0.25 mn 0.75 o 2.5 ]-0.9[Li 0.5 Ni 0.25 mn 0.75 o 2 ], the preparation steps are basically the same as in Example 1, except that the calcination temperature in step 3) is 900°C, and the calcination time is 15h.

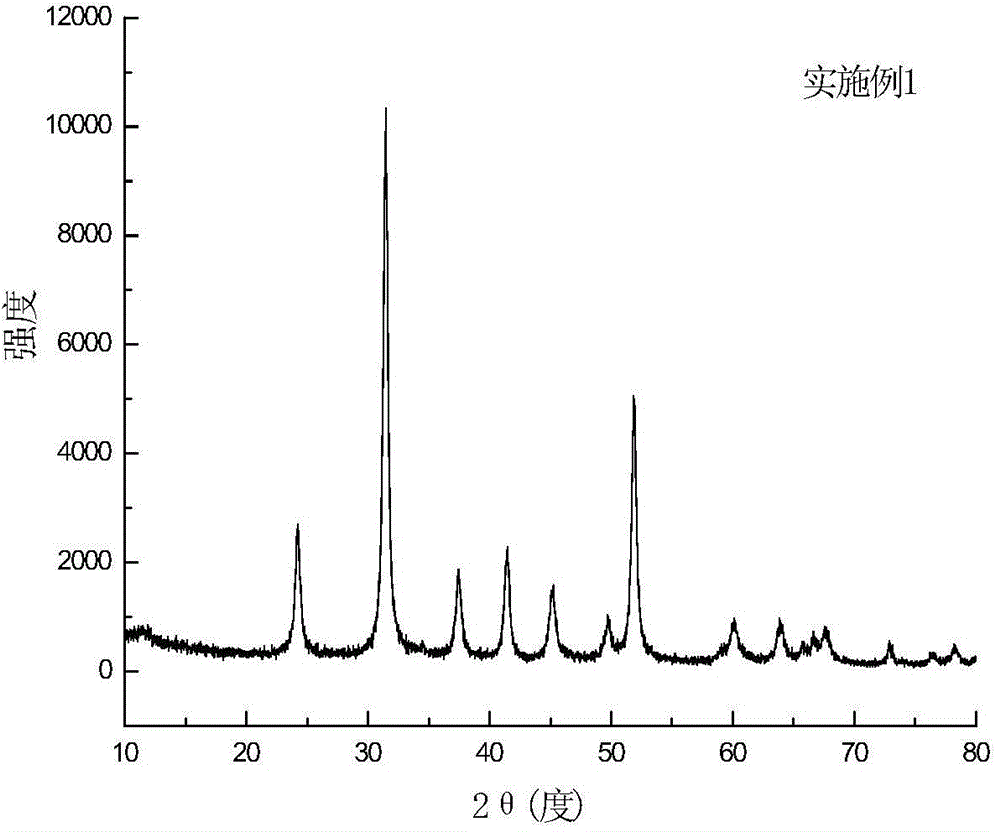

[0046] Figure 5 The XRD pattern of the modified spinel type lithium ion battery cathode material prepared for embodiment 1, 2 and 3 shows in the figure: the structure of the material in embodiment 1, embodiment 2 and embodiment 3 is all spinel phase (Fd-3m) and layered phase material (R-3m) structure composite, when the temperature rises, the (006) / (102) peak splitting in the material structure is obvious, indicating that the layered phase material in the composite material The layered structure is better, which shows that the temperature affects the structure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com