Copper zinc silicon base powdery brazing material containing alterant and preparation method thereof

A modificator, silicon-based technology, applied in the field of powder metallurgy, can solve problems such as improper smelting atomization process, unstable powder quality, poor composition design, etc. The effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

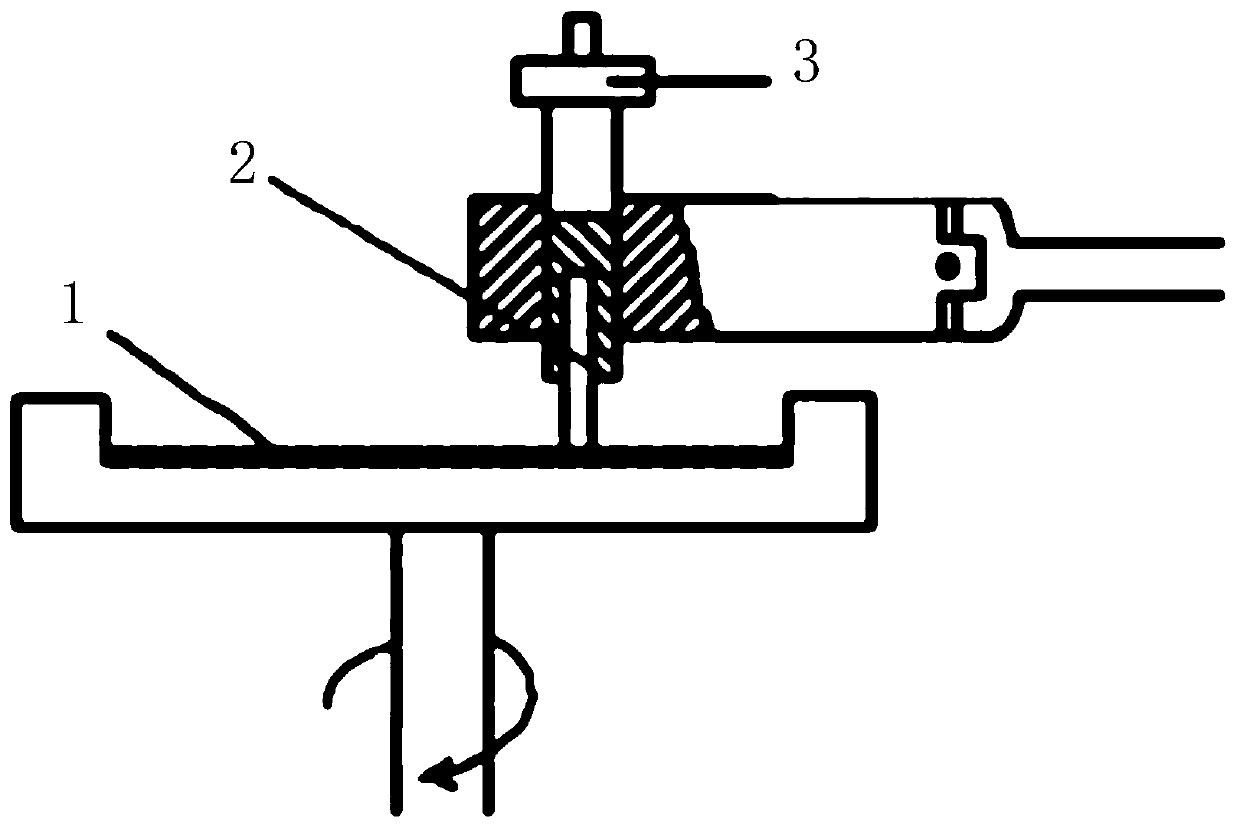

Method used

Image

Examples

Example Embodiment

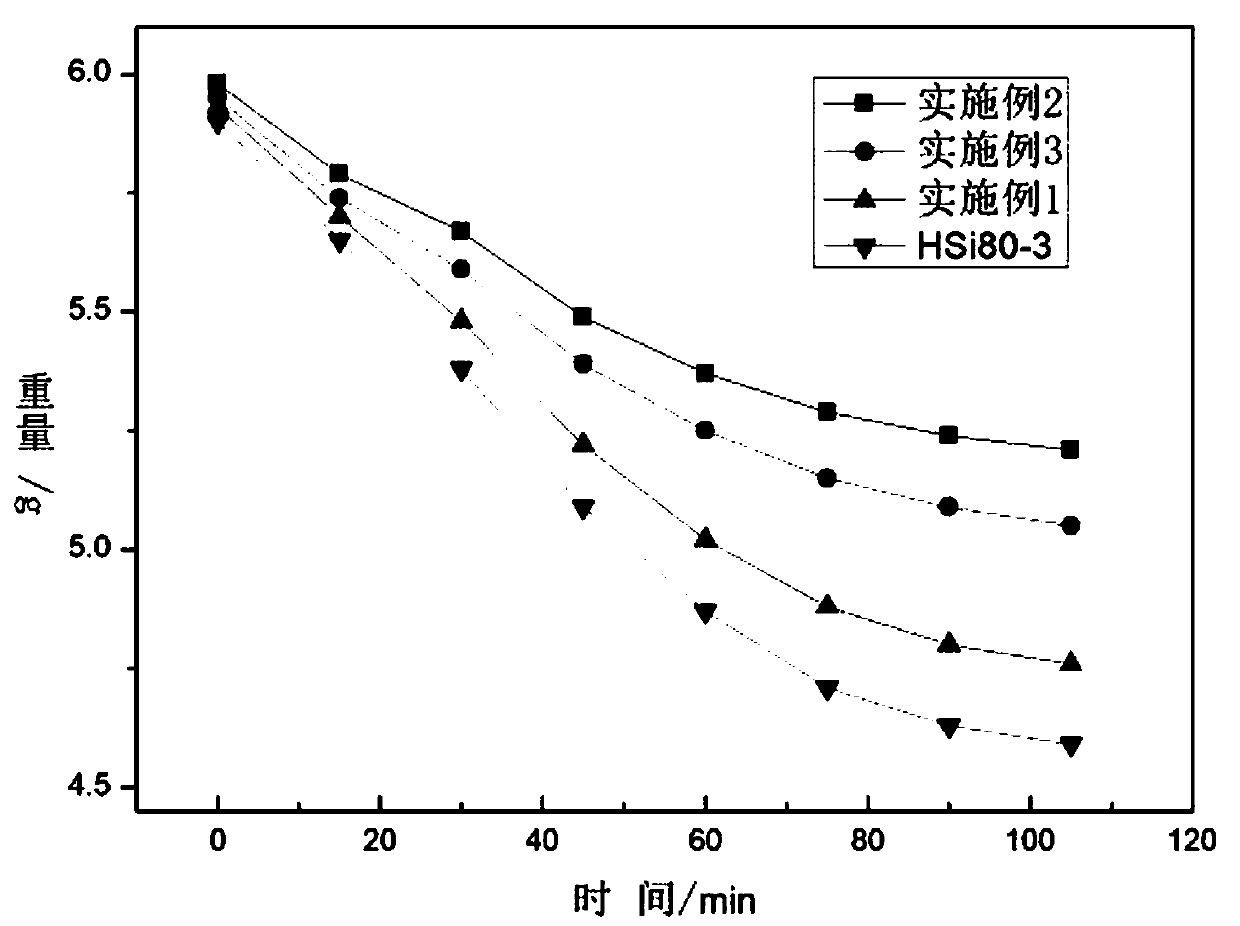

[0045] Example 1

[0046] The chemical composition of copper-zinc-silicon-based powder brazing material containing trace modifier is designed as: zinc 30 wt %, silicon 4 wt %, tin 1 wt %, Indium 0.5 wt %, lanthanum cerium composite metal 1 wt %, nickel 0.2 wt %, manganese 0.8 wt %, iron 1 wt %, the balance of copper and inevitable impurity elements.

[0047] Taking the preparation of 100 parts of copper-zinc-silicon-based powder brazing material as an example, firstly, 9 parts of copper and 1 part of silicon are mixed and smelted into copper-silicon master alloy, and 7 parts of copper and 3 parts of nickel are mixed and smelted into copper-nickel master alloy. ; Roll the iron sheet into a foil strip with a thickness of 0.2 mm and a width of 5 mm, and roll 0.5 parts of metal indium and 1 part of lanthanum-cerium composite metal into the foil strip and compact it. Then, the remaining copper, copper-silicon master alloy, and copper-nickel master alloy were melted and s...

Example Embodiment

[0051] Example 2

[0052] The chemical composition of copper-zinc-silicon-based powder brazing material containing trace modifier is designed as: zinc 28 wt %, silicon 5 wt %, tin 2 wt %, Indium 0.8 wt %, lanthanum cerium composite metal 1 wt %, nickel 1 wt %, manganese 1 wt %, iron 1 wt %, the balance of copper and inevitable impurity elements.

[0053] Taking the preparation of 100 parts of silicon brass pre-alloy powder as an example, firstly, 9 parts of copper and 1 part of silicon are mixed and smelted into a copper-silicon master alloy, 7 parts of copper and 3 parts of nickel are mixed and smelted into a copper-nickel master alloy; The sheet was rolled into a foil strip with a thickness of 0.2 mm and a width of 5 mm, and 0.8 parts of metal indium and 1 part of lanthanum-cerium composite metal were rolled into the foil strip and compacted. Then, the remaining copper, copper-silicon master alloy and copper-nickel master alloy were melted and smelted in an intermed...

Example Embodiment

[0057] Example 3

[0058] The chemical composition of copper-zinc-silicon-based powder brazing material containing trace modifier is designed as: zinc 30 wt %, silicon 6 wt %, tin 1 wt %, Indium 2 wt %, lanthanum cerium composite metal 0.5 wt %, nickel 1 wt %, manganese 1 wt %, iron 1 wt %, the balance of copper and inevitable impurity elements.

[0059] Taking the preparation of 100 parts of silicon brass pre-alloy powder as an example, firstly, 9 parts of copper and 1 part of silicon are mixed and smelted into a copper-silicon master alloy, 7 parts of copper and 3 parts of nickel are mixed and smelted into a copper-nickel master alloy; The sheet is rolled into a foil strip with a thickness of 0.2 mm and a width of 5 mm, and 2 parts of metal indium and 0.5 part of lanthanum-cerium composite metal are rolled into the foil strip and compacted. Then, the remaining copper, copper-silicon master alloy and copper-nickel master alloy were melted and smelted in an intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com