A method of laser surface remelting and chemical dealloying combined to prepare micro-nano structured bulk silicon materials

A technology of chemical dealloying and micro-nano structure, applied in the field of material preparation, can solve the problems of low repetition rate, low efficiency, complex equipment, etc., and achieve the effect of short cycle, simple conditions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Raw materials:

[0026] (1) Aluminum-silicon block alloy, Al:Si=95:5wt.%.

[0027] (2) Etching solution: 3mol / L HCL solution.

[0028] 2. Preparation method

[0029] Step 1. Preparation of precursor alloy material:

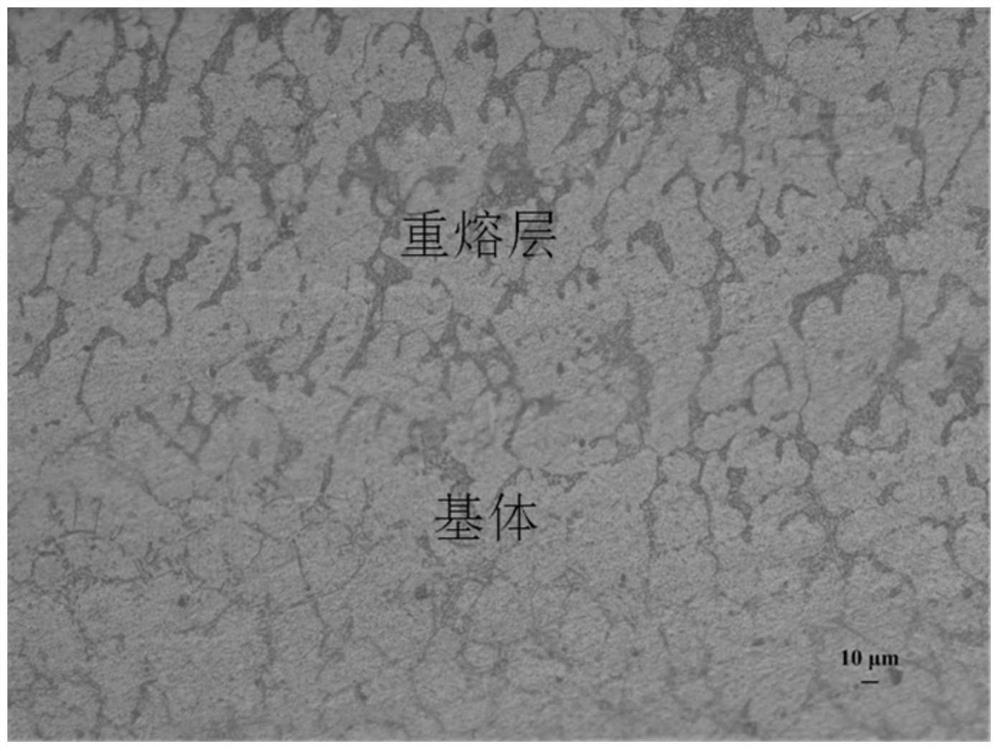

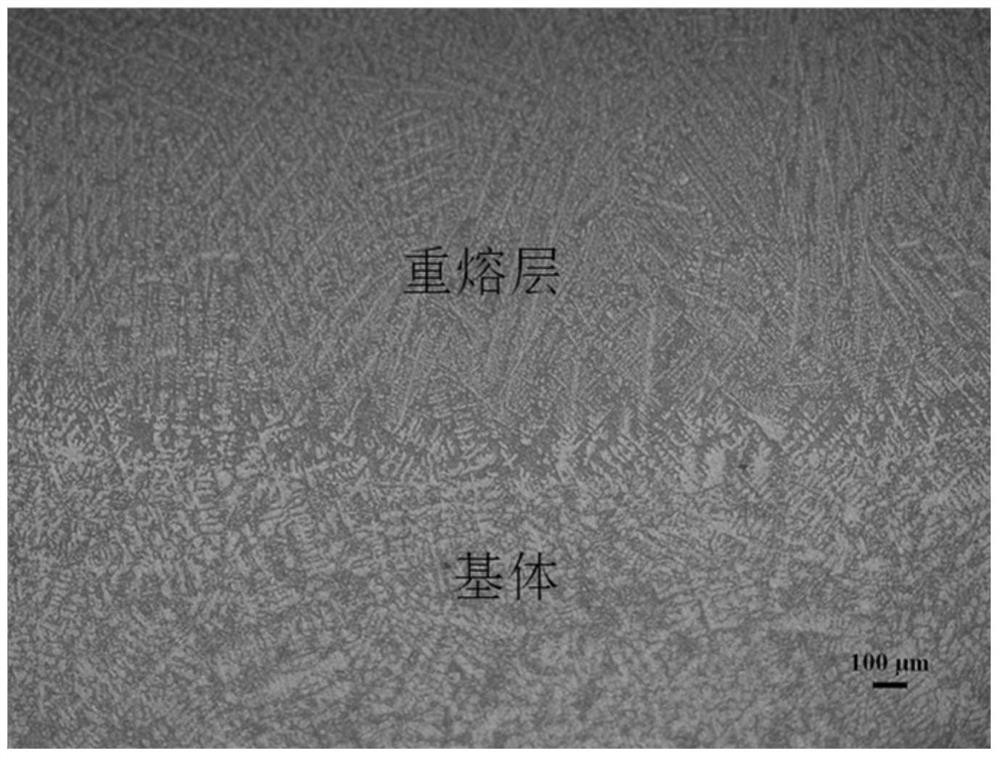

[0030] YLS-6000 fiber laser is used for remelting treatment, laser power: 4kW, scanning speed: 8mm / s, spot diameter: 6mm, shielding gas: argon, shielding gas flow: 18L / min. After laser treatment, wire cutting is used to separate the remelted layer from the substrate to obtain the precursor alloy material.

[0031] Step 2, chemical dealloying treatment:

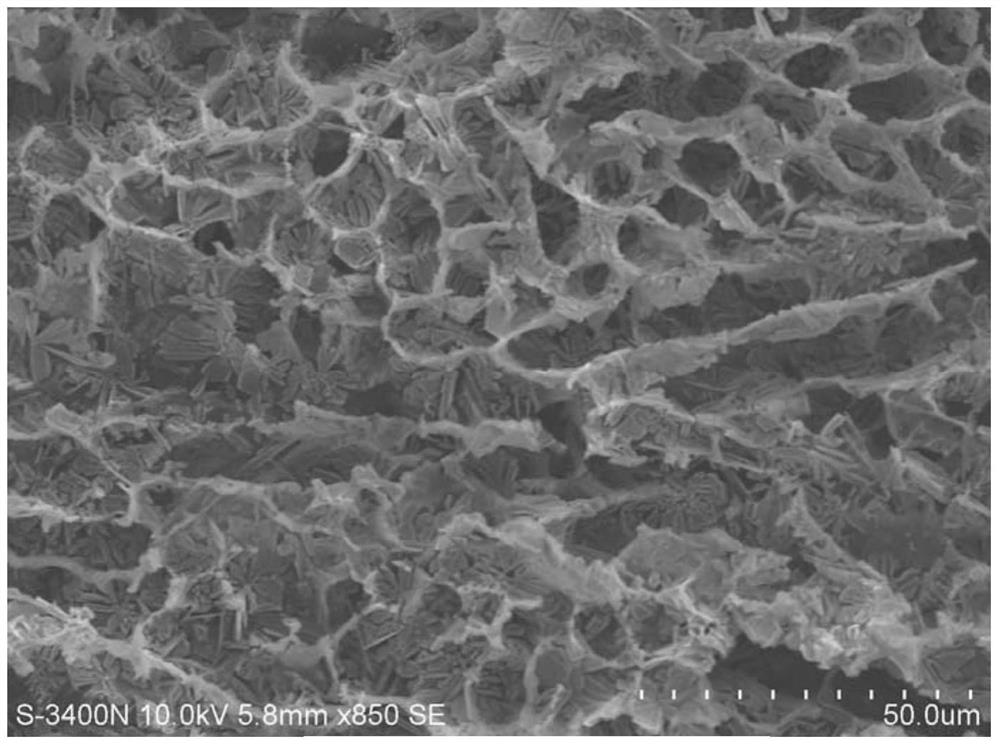

[0032] Immerse the precursor alloy material obtained by the remelting treatment into a 3mol / L HCL solution and corrode for 2 hours until no bubbles are generated and the aluminum is completely dissolved. Clean the micro-nano structure intermediate obtained after corrosion with an ethanol solution, and then use The HF with a mass percentage of 2% is used for cleaning, and finally a silicon material w...

Embodiment 2

[0034] 1. Raw materials:

[0035] (1) Aluminum-silicon block alloy, Al:Si=80:20wt.%.

[0036] (2) Etching solution: 3mol / L HCL solution.

[0037] 2. Preparation method

[0038] Step 1. Preparation of precursor alloy material:

[0039] Using YLS-6000 fiber laser for remelting treatment, laser power: 5.5kW, scanning speed: 10mm / s, spot diameter: 6mm, shielding gas: argon, shielding gas flow: 18L / min. After laser treatment, wire cutting is used to separate the remelted layer from the substrate to obtain the precursor alloy material.

[0040] Step 2, chemical dealloying treatment:

[0041] Immerse the precursor alloy material obtained by the remelting treatment into a 3mol / L HCL solution and corrode for 8 hours until no bubbles are generated and the aluminum is completely dissolved. Clean the micro-nano structure intermediate obtained after corrosion with an ethanol solution, and then use The HF with a mass percentage of 2% is used for cleaning, and finally a bulk silicon mat...

Embodiment 3

[0043] 1. Raw materials:

[0044] (1) Aluminum-silicon block alloy, Al:Si=50:50wt.%.

[0045] (2) Etching solution: 3mol / L HCL solution.

[0046] 2. Preparation method

[0047] Step 1. Preparation of precursor alloy material:

[0048] Using YLS-6000 fiber laser for remelting treatment, laser power: 5.5kW, scanning speed: 10mm / s, spot diameter: 6mm, shielding gas: argon, shielding gas flow: 18L / min. After laser treatment, wire cutting is used to separate the remelted layer from the substrate to obtain the precursor alloy material.

[0049] Step 2, chemical dealloying treatment:

[0050] Immerse the precursor alloy material obtained by the remelting treatment in a 3mol / L HCL solution and corrode for 12 hours until no bubbles are generated and the aluminum is completely dissolved. Clean the micro-nano structure intermediate obtained after corrosion with an ethanol solution, and then use The HF with a mass percentage of 2% is used for cleaning, and finally a bulk silicon mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com