A viscose short fiber cutting knife manufactured by powder metallurgy method of mixing pure powder

A viscose staple fiber, powder metallurgy technology, applied in other manufacturing equipment/tools, mechanical equipment, turbines, etc., can solve the problems of coarse grains of the casting structure, jumping edge, unsatisfactory service life, etc., to improve corrosion resistance. , the structure of small grains, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

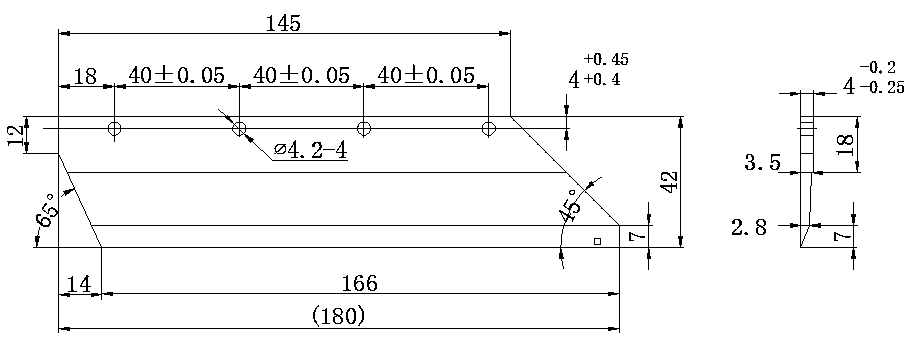

Image

Examples

Embodiment Construction

[0016] The invention is a viscose staple fiber cutting knife manufactured by powder metallurgy method of mixing pure powder, the components of the viscose staple fiber cutting knife are composed of Co, Cr, Cr 3 C 2 , W, WC, Ni, Mo, Cu, NbC 9 kinds of pure powder are mixed, the mixed powder is pressurized and pressed in a mold of the required shape; the molded body is sintered in a vacuum furnace at 1200 ℃ ~ 1300 ℃, and its hardness is HRC35 ~ Continuously adjustable within 55°;

[0017] Components Co, Cr, Cr of the viscose staple fiber cutting knife 3 C 2 , W, WC, Ni, Mo, Cu, NbC 9 kinds of pure powder content (weight %): Co: 40 ~ 60%; Cr: 20 ~ 30%; Cr 3 C 2 : 5~15%;W:3~9%; WC: 0~5%; Ni:3~9%; Mo:0~5%; Cu:0~5%; NbC: 3~7%; The addition of Cu and Cu is the main feature of the components of the present invention;

[0018] A specific embodiment is: with 11kgCr powder, 4.1kg Cr 3 C 2 powder, 2.65kgNbC powder, 1.45kgWC powder, 1.5kgW powder, 3kgNi powder, 0.6kgCu powder, 0.75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com