Preparation method of water soluble fluorescent nano-particles

A fluorescent nanometer, water-soluble technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor particle size uniformity, not easy to disperse, low fluorescence sensitivity, etc., and achieve uniform particle size, low cost, and sensitive fluorescence intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Put 0.02 g of polystyrene-b-poly(2-vinylpyridine) (molecular weight 17.5K-b-9.5K) and 0.005 g of fluorescent substance perylene in a 50 ml glass flask with a reflux device, and then Add 20 grams of acetic acid into the bottle; heat the liquid in the glass flask to 110°C and keep it for 10 hours to obtain solution 1, which is directly used in the next reaction;

[0021] 2) Mix the above solution 1 and ethyl bromide at a volume ratio of 5:1, heat it to 110°C in a 50ml glass flask, and keep it for 3 hours, then redisperse the colloidal intermediate obtained by centrifugation in 20g of water Obtain solution 2;

[0022] 3) Put the solution 2 of the previous step in a 25 ml reaction kettle and heat it to 80°C and keep it for 2 hours to obtain polymer nanofluorescent microspheres dispersed in water.

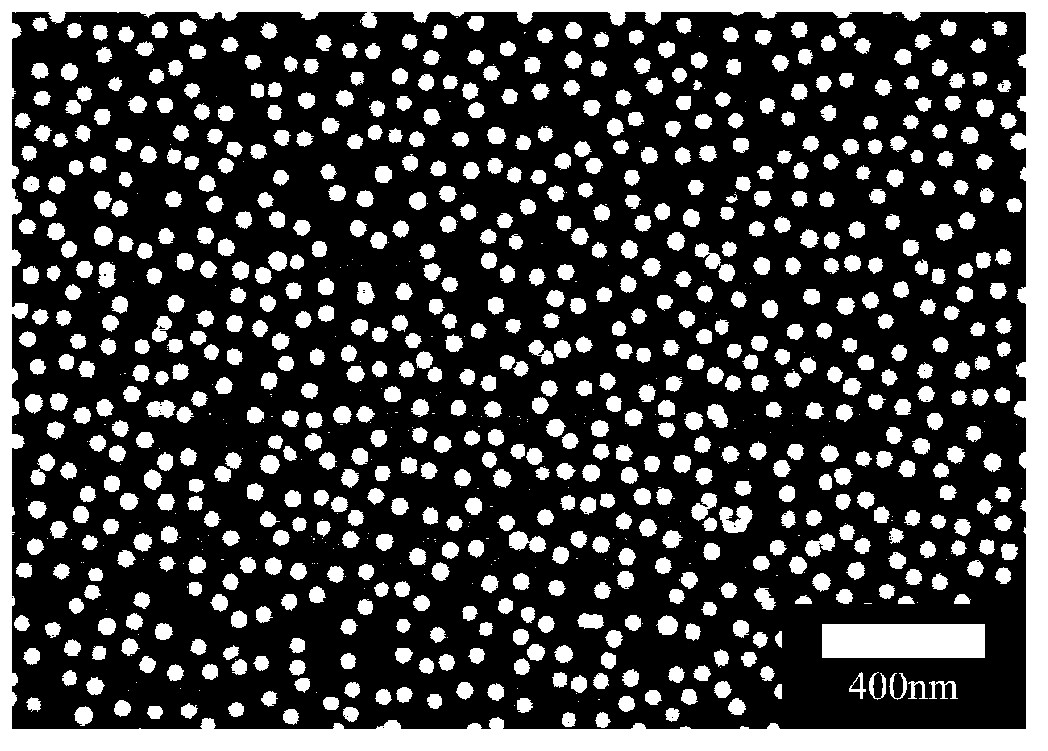

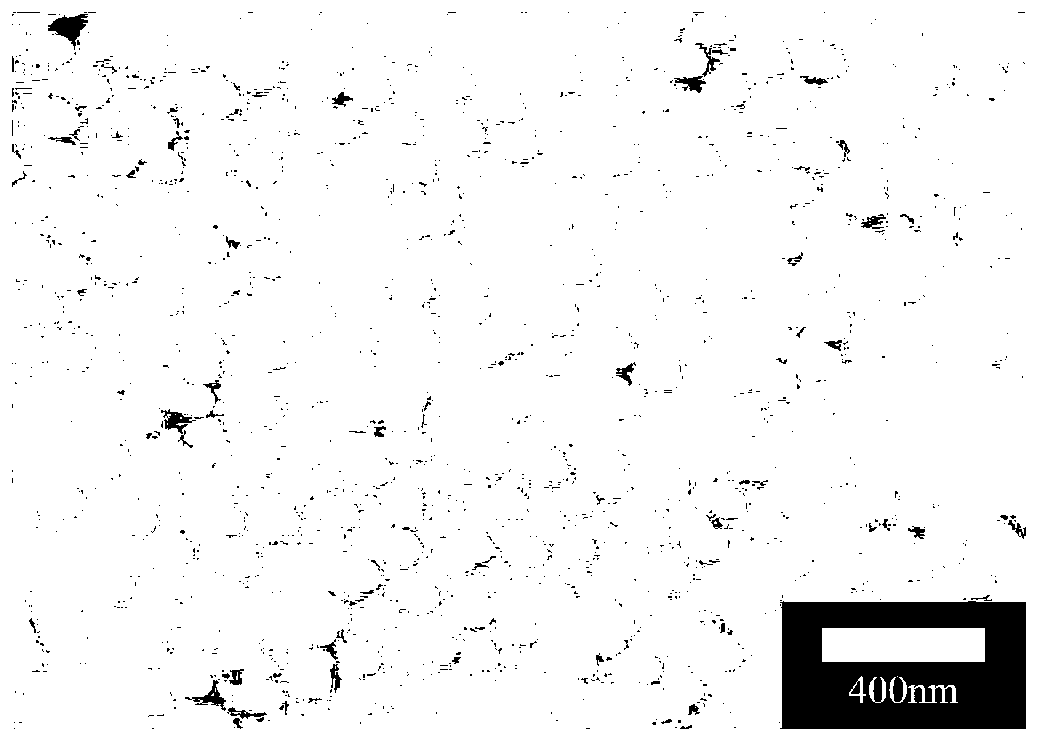

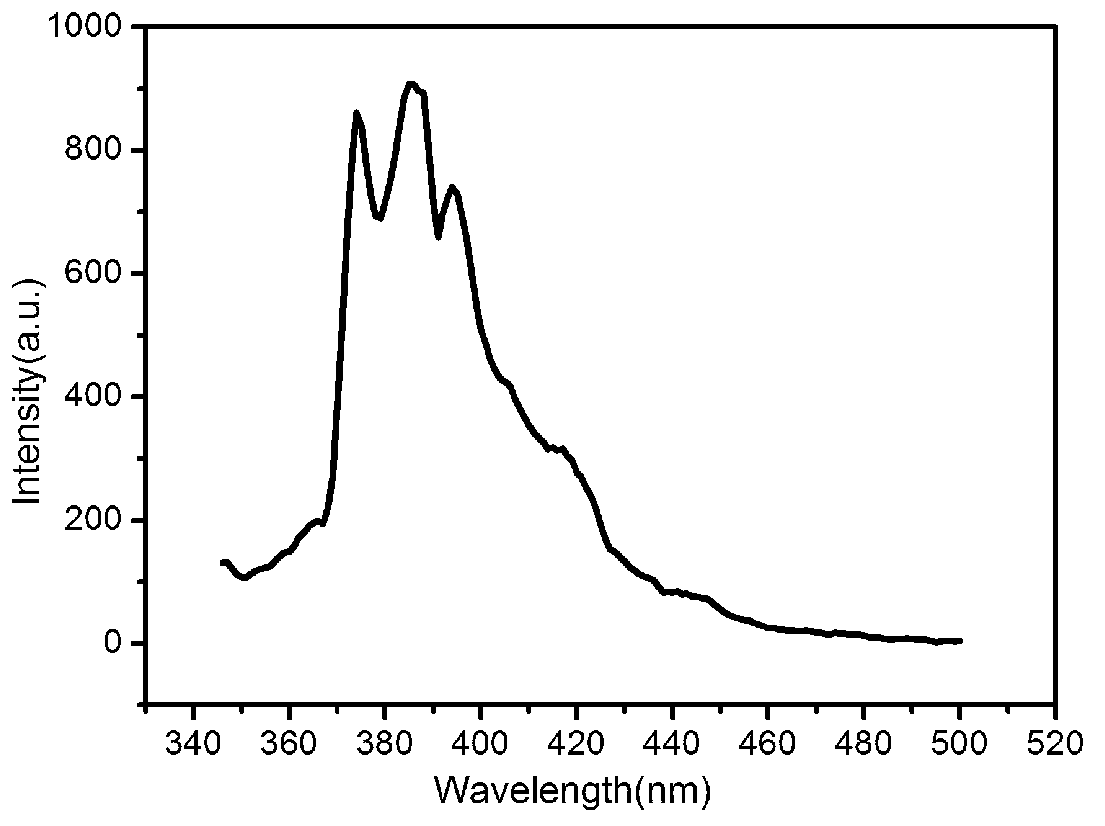

[0023] The scanning electron microscope (SEM) image of the obtained nanofluorescent microspheres is shown in figure 1 As shown, the average particle diameter of the fluoresc...

Embodiment 2

[0025] Example 2 Compared with Example 1 step 1), the amount of block copolymer and fluorescent substance was increased to increase the yield, and the dissolution temperature was increased to reduce the time required for dissolution.

[0026] 1) Put 0.2 g of polystyrene-b-poly(2-vinylpyridine) (molecular weight 17.5K-b-9.5K) and 0.05 g of fluorescent substance perylene in a 50 ml glass flask with a reflux device, and then Add 20 grams of acetic acid into the bottle; heat the liquid in the glass flask to 130°C and keep it for 5 hours to obtain solution 1, which is directly used in the next reaction;

[0027] 2) Mix the solution 1 of the previous step and ethyl bromide at a volume ratio of 6:1, heat it to 110°C in a 50ml glass flask, and keep it for 3 hours, then redisperse the colloidal intermediate obtained by centrifugation in 10g of water Obtain solution 2;

[0028] 3) Put the solution 2 of the previous step in a 25 ml reaction kettle and heat it to 130° C. and keep it for ...

Embodiment 3

[0031] Compared with Example 1, Example 3 changed the molecular weight of the block copolymer used and the weight ratio of the segments, and increased the temperature of the quaternization reaction to obtain fluorescent microspheres with different particle sizes and reduce the quaternization reaction. the time required.

[0032] 1) Put 0.04 g of polystyrene-b-poly(2-vinylpyridine) (molecular weight 50K-b-16.5K) and 0.01 g of fluorescent substance perylene in a 50 ml glass flask with a reflux device, and then Add 20 grams of acetic acid to the bottle; heat the liquid in the glass flask to 110°C and keep it for 10 hours to obtain solution 1, which is directly used in the next reaction;

[0033] 2) Mix the above solution 1 and ethyl bromide at a volume ratio of 5:1, heat it to 130°C in a 50ml glass flask, and keep it for 1 hour, then redisperse the colloidal intermediate obtained by centrifugation in 15g of water Obtain solution 2;

[0034] 3) Put the solution 2 of the previous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com