A kind of high durability enhanced proton exchange membrane and its preparation method and application

A proton exchange membrane, durable technology, used in chemical instruments and methods, final product manufacturing, climate sustainability, etc., can solve problems such as low utilization of metal oxide surfaces, decreased proton conductivity, and degradation of single cell performance. , to achieve the effect of fast and repeatable preparation process, safe and controllable preparation process, and reduced performance decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

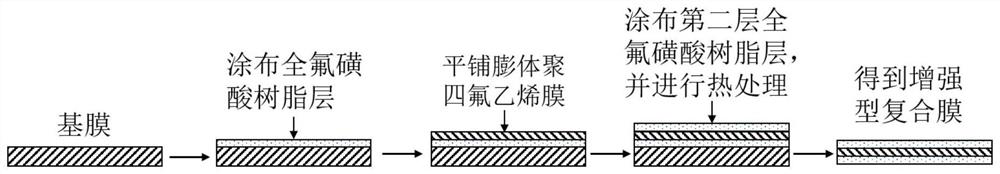

[0039] The preparation method of the high-durability enhanced proton exchange membrane in the present embodiment comprises the following steps:

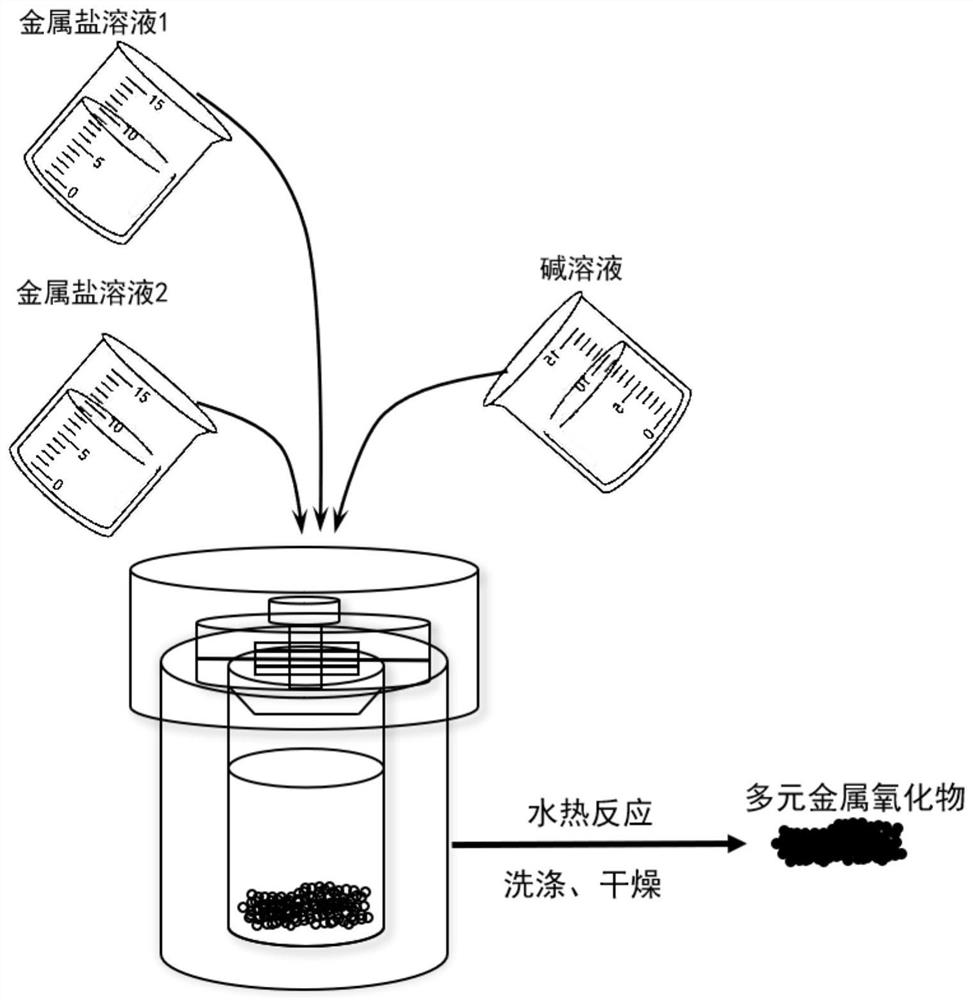

[0040] (1) Weigh 0.36g NaOH with an electronic balance and dissolve it in 20mL deionized water to prepare a 0.45mol / L NaOH alkaline solution, and weigh 1.3g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 8mL deionized water, and at the same time, the purchased 50wt% Mn(NO 3 ) 3 Diluted to 0.1476mol / L, respectively placed in an ultrasonic cleaner and vibrated until a uniform transparent solution was formed. The prepared Ce(NO 3 ) 3 ·6H 2 O aqueous solution and 2 mL diluted Mn(NO 3 ) 3 The aqueous solution was mixed and transferred to the PTFE liner, then the NaOH aqueous solution was poured into the PTFE liner, and the Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.1mol / L, Mn(NO 3 ) 3 The concentration of Ce is 0.01mol / L, and the molar ratio of Ce to Mn is 10:1;

[0041] (2) Seal the polytetrafluoroethylene liner and place it in...

Embodiment 2

[0049] The preparation method of the high-durability enhanced proton exchange membrane in the present embodiment comprises the following steps:

[0050] (1) Weigh 0.25g NaOH with an electronic balance and dissolve it in 20mL deionized water to prepare a 0.31mol / L NaOH alkaline solution, and weigh 1.3g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 9mL deionized water, and at the same time, the purchased 50wt% Mn(NO 3 ) 3 Diluted to 0.1476mol / L, respectively placed in an ultrasonic cleaner and vibrated until a uniform transparent solution was formed. The prepared Ce(NO 3 ) 3 ·6H 2 O aqueous solution and 1 mL diluted Mn(NO 3 ) 3 The aqueous solution was mixed and transferred to the PTFE liner, then the NaOH aqueous solution was poured into the PTFE liner, and the Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.1mol / L, Mn(NO 3 ) 3 The concentration of Ce is 0.005mol / L, and the molar ratio of Ce to Mn is 20:1;

[0051] (2) Seal the polytetrafluoroethylene liner and place it i...

Embodiment 3

[0059] The preparation method of the high-durability enhanced proton exchange membrane in the present embodiment comprises the following steps:

[0060] (1) Weigh 0.64g NaOH with an electronic balance and dissolve it in 20mL deionized water to prepare a 0.80mol / L NaOH alkaline solution, and weigh 1.3g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 9.5mL deionized water, and the purchased 50wt% Mn(NO 3 ) 3 Diluted to 0.1476mol / L, respectively placed in an ultrasonic cleaner and vibrated until a uniform transparent solution was formed. The prepared Ce(NO 3 ) 3 ·6H 2 O aqueous solution and 0.5mL diluted Mn(NO 3 ) 3 The aqueous solution was mixed and transferred to the PTFE liner, then the NaOH aqueous solution was poured into the PTFE liner, and the Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.1mol / L, Mn(NO 3 ) 3 The concentration of Ce is 0.0025mol / L, and the molar ratio of Ce to Mn is 40:1;

[0061] (2) Seal the polytetrafluoroethylene lining and place it in a high-pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com