Power grid corona monitor and preparation method thereof

A monitor and grid electricity technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of short detection distance, many human factors, and large detection errors of ultrasonic corona detection devices, and achieve enhanced conductivity and transparency. Light rate, easy to obtain processing, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

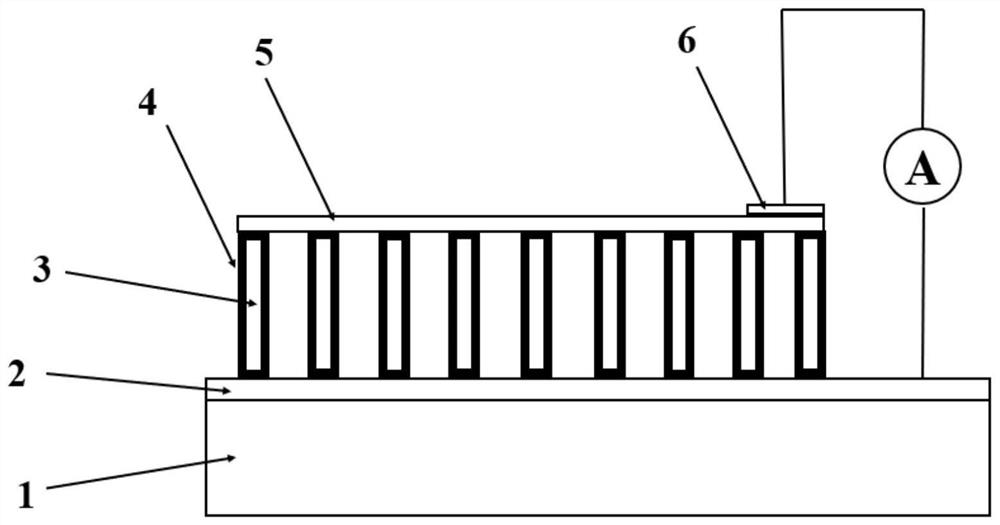

[0044] A preparation method of a power grid corona monitor, comprising the following steps:

[0045] Step 1. Soak the FTO substrate 1 in acetone, ethanol, and deionized water for 10 minutes in sequence, then take it out, rinse it with deionized water, and dry it with dry nitrogen;

[0046] Step 2, take Ga(NO) with a concentration of 10-15g / L 3 ) 3 The solution is placed in the inner liner of the reactor, and then the FTO substrate 1 after drying with dry nitrogen in step 1 is leaned against the inner liner of the reactor, and is immersed in Ga(NO) 3 ) 3 In the solution, wherein the fluorine-doped tin oxide layer 2 is toward the side of the reactor liner on which it is leaned;

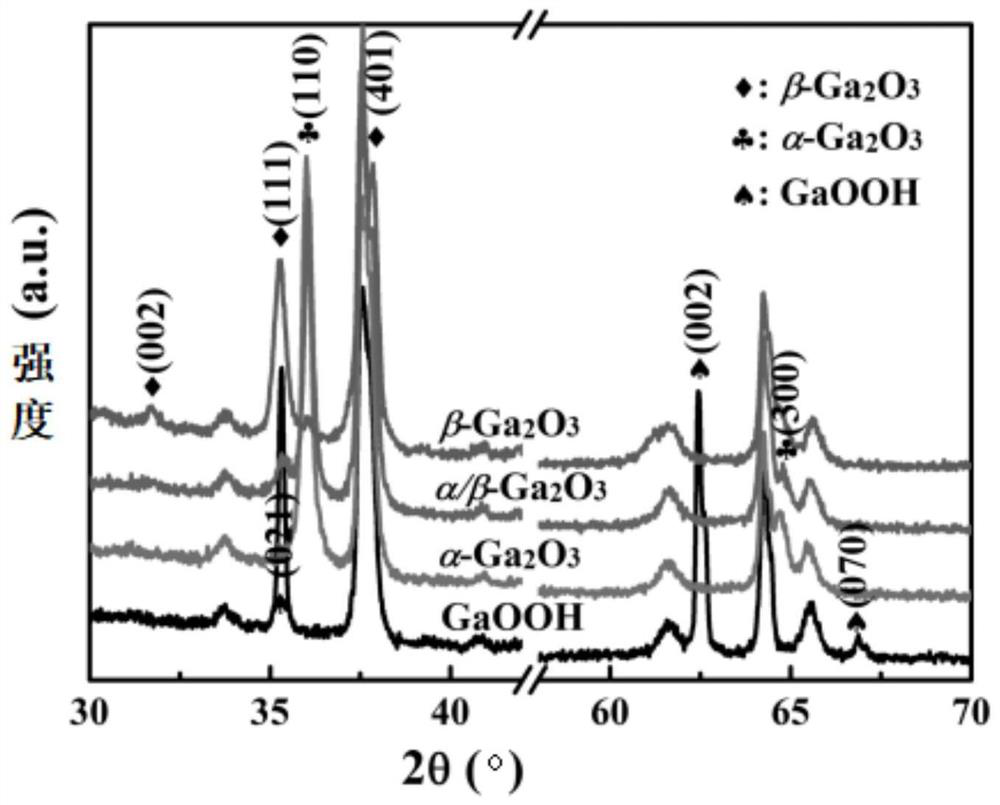

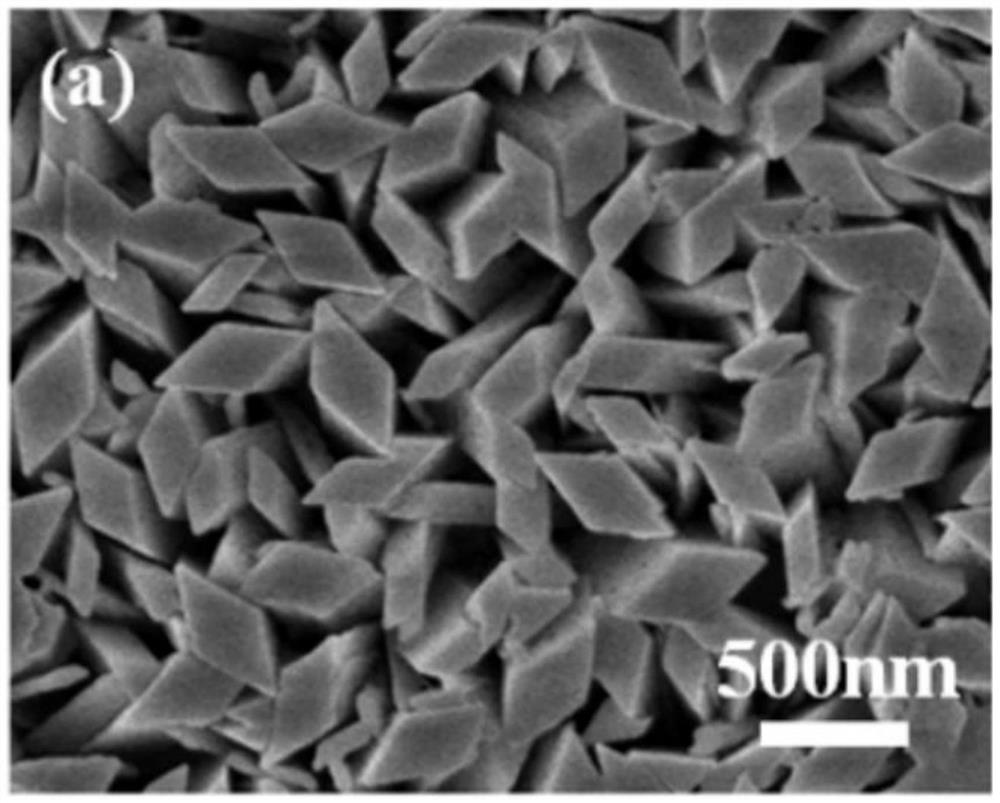

[0047] Step 3: Transfer the reaction kettle in Step 2 to an oven, react at 150° C. for 12 hours, then take out the FTO substrate 1, wash it alternately with deionized water and absolute ethanol, and dry it in a high-temperature furnace. Anneal at 400-500℃ for 3.0-4.0 hours to obtain α-Ga 2 O 3 nan...

Embodiment 1

[0053] (1) Soak the FTO substrate 1 in acetone, ethanol, and deionized water for 10 minutes in sequence, rinse with deionized water after taking it out, and dry it with dry nitrogen; (2) Take 30 mL of 5 g / L Ga(NO 3 ) 3 The solution is placed in the inner liner of the reactor, and then the FTO substrate 1 obtained in step (1) is leaned against the inner liner of the reactor, and immersed in Ga(NO) 3 ) 3 In the solution, the fluorine-doped tin oxide layer 2 faces downward (that is, towards the side of the inner tank of the reactor that is leaned against); (3) transfer the reactor to an oven, react at 150 ° C for 12 hours, then take it out and use Deionized water and absolute ethanol were alternately washed 3 times, and after drying, annealed in a high temperature furnace at 400 °C for 1.0 hours to obtain α-Ga 2 O 3 nanopillar arrays, then the high temperature furnace was rapidly heated to 750°C and annealed for 10 minutes to obtain α / β-Ga 2 O 3 Junction nanopillar array 4;...

Embodiment 2

[0060] Steps (1), (4) and (5) are all identical with embodiment 1;

[0061] Ga(NO in step (2) 3 ) 3 The concentration of the solution is 10g / L;

[0062] Step (3): react at 150°C for 12h, hydrothermally grow gallium oxyhydroxide, then transfer GaOOH to a high temperature furnace for annealing, and anneal at 400°C for 1.5 hours to obtain α-Ga 2 O 3 nanopillar arrays, then the high-temperature furnace was rapidly heated to 700 °C and annealed for 20 minutes to obtain α / β-Ga 2 O 3 Junction Nanopillar Array 4; Resulting α / β-Ga 2 O 3 Crystal structure, chemical composition of junction nanopillar array 4 and Ti-based 3 C 2 / α / β-Ga 2 O 3 The optoelectronic properties of the grid corona monitors of the nanopillar array van der Waals heterojunction are all similar to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com