Preparation method of self-supporting flexible conductive super-hydrophobic film

A flexible conductive and super-hydrophobic technology, applied in the field of preparation of flexible conductive and super-hydrophobic films, can solve problems such as the inability to realize large-area production of flexible conductive and super-hydrophobic functional films, and achieve continuous production, good conductivity, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

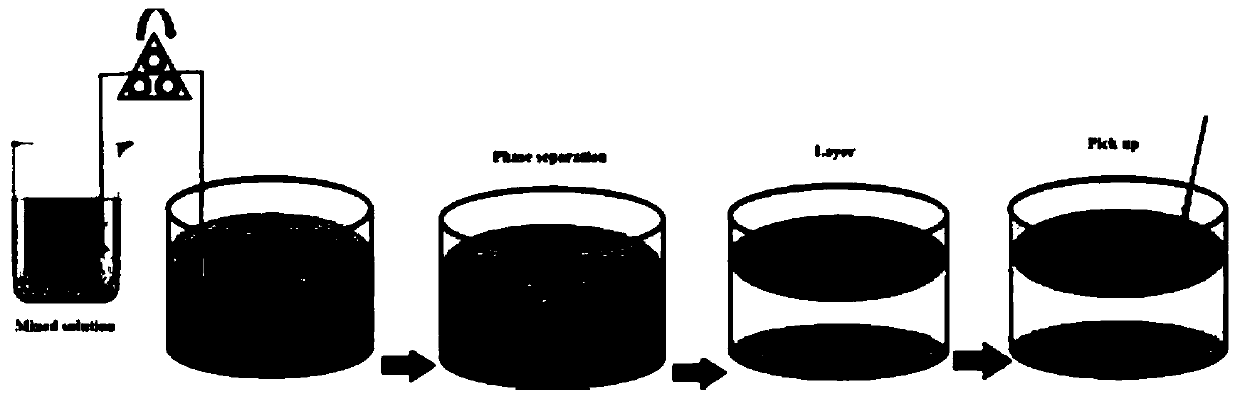

[0029] A method for preparing a self-supporting flexible conductive super-hydrophobic film, using a solvent-non-solvent method to make conductive nanomaterials form a self-supporting flexible conductive super-hydrophobic film on the surface of a liquid phase system; figure 1 As shown, firstly, the mixed solution of CNT / TPE is prepared; then, the prepared mixed solution of CNT and TPE is injected into water, so that the CNT and TPE solution forms a film on the air / water interface; finally, the CNT / TPE on the water surface film, transferred out of the air / water interface, and dried to obtain a self-supporting flexible conductive superhydrophobic film.

[0030] Specifically follow the steps below:

[0031] Step 1: Prepare TPE Solution

[0032] Step 2: Prepare CNT and TPE mixed solution

[0033] Step 3: Form TPE / CNT film on the interface

[0034] The specific process of step 1 is as follows:

[0035] The high-molecular polymer TPE has the advantages of non-toxicity and good fl...

Embodiment 1

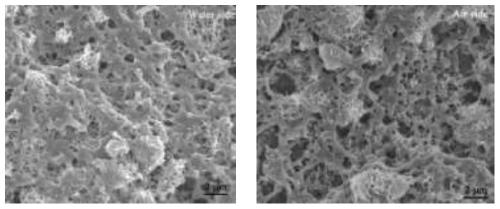

[0044]A hybrid film with conductive superhydrophobic properties was prepared by interfacial film formation. (1) Prepare a TPE / THF (tetrahydrofuran) solution with a mass concentration of 10 mg / ml, and accelerate the dissolution of the TPE (high molecular polymer) at a rate of 1.2 Kr / min by emulsification shear. (2) Add carbon nanotubes into the TPE solution, wherein the mass concentration of carbon nanotubes in the mixed solution is 2 mg / ml, and disperse the mixed solution by ultrasonic waves. (3) Measure 400ml of deionized water as a non-good solvent, pour 50ml of the mixed solution slowly (80ml / min) or add it into the water with a peristaltic pump. (4) After standing still for 30 minutes, the film is transferred out of the liquid surface using a ring device, and dried at room temperature to obtain an independent self-supporting functional film material, such as image 3 The microstructural morphology of the different surfaces of the film was observed by scanning electron mic...

Embodiment 2

[0046] A hybrid film with conductive superhydrophobic properties was prepared by interfacial film formation. (1) Prepare a TPE / THF (tetrahydrofuran) solution with a mass concentration of 15 mg / ml, and accelerate the dissolution of TPE (high molecular polymer) at a rate of emulsification shear of 1.5 Kr / min. (2) Add CNTs into the TPE solution, wherein the mass concentration of CNTs in the mixed solution is 1.5 mg / ml, and disperse the mixed solution by ultrasonic waves. (3) Measure 400ml of deionized water as a non-good solvent, pour 50ml of the mixed solution slowly (50-80ml / min) or add it to the water with a peristaltic pump. (4) After standing still for 30 minutes, the film is transferred out of the liquid surface using a ring device to prepare an independent self-supporting functional film material, such as image 3 The microstructural morphology of the different surfaces of the film was observed by scanning electron microscope as shown. Specific application effects such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com