Double-mouse-cage composite cage bar efficient motor rotor and manufacturing method thereof

A technology of composite cage bars and double squirrel cages, which is applied in the field of electric motors, can solve the problems of failure to achieve the qualified rate of aluminum casting, high overall cost of rotors, and poor versatility of parts, so as to improve starting performance and working performance and shorten production The effect of cycle, production and manufacturing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and description of the accompanying drawings.

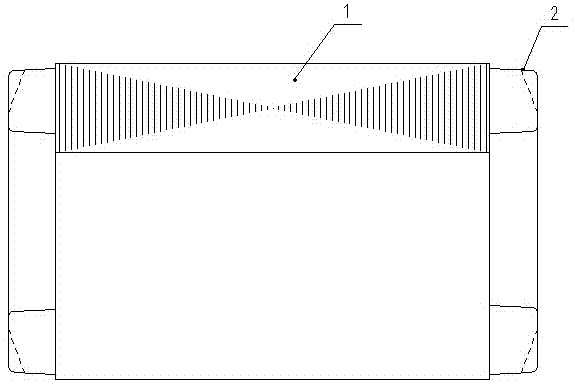

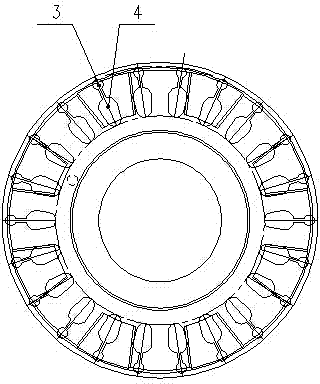

[0033] A high-efficiency motor rotor with double squirrel-cage composite cage bars, including the rotor, the iron core of the rotor includes inner and outer squirrel cages where the squirrel-cage bars are close to or tangent to each other, and the ends of the squirrel-cage bars at both ends of the inner and outer squirrel-cages The rings 2 are respectively connected as one; in order to improve the starting characteristics of the asynchronous motor, the outer cage bar 3 of the outer cage is made of aluminum casting material with high resistivity, and the inner cage bar 4 is pure copper (copper) rod with low resistivity , The section of the inner and outer squirrel cage bars in the iron core of the rotor is circular, oval, pear-shaped or knife-shaped. The total cross-section of the inner and outer cage bars of each cage corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com