Heat treatment technology for reducing deformation of spiral bevel gear for hay mower

A bevel gear and lawn mower technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of inability to guarantee consistent product performance and low yield, and achieve reduced deformation, reduced temperature difference, and good cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

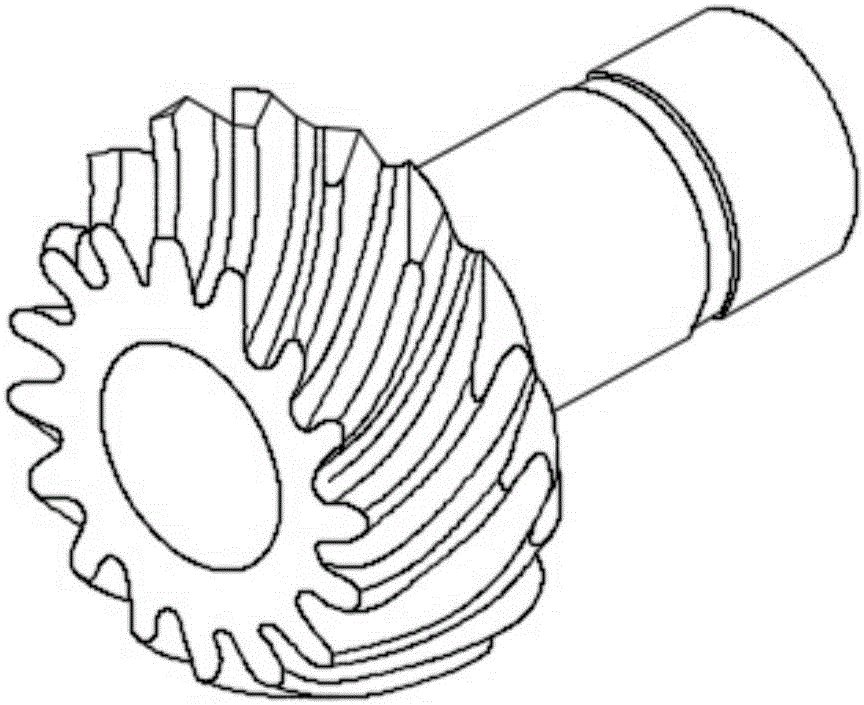

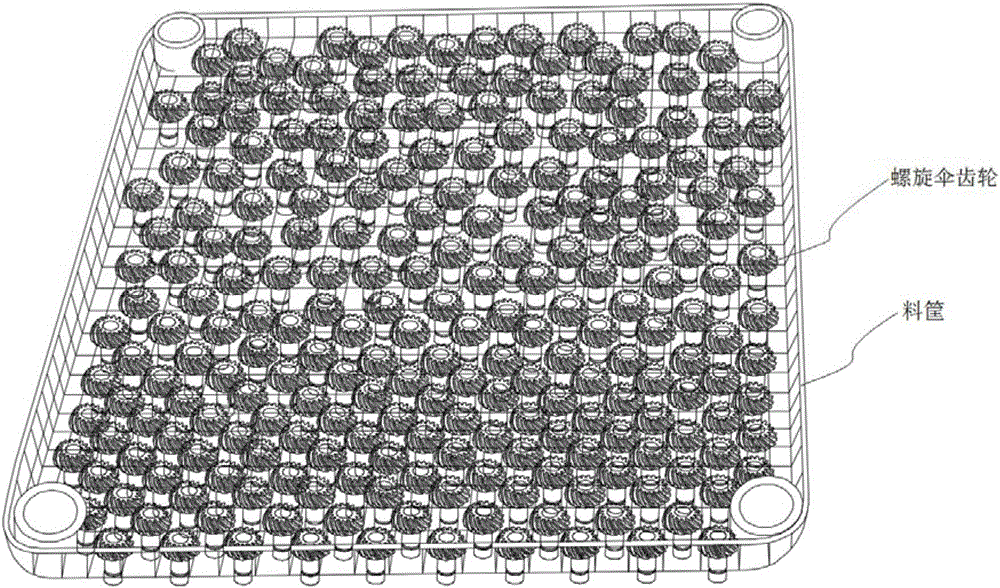

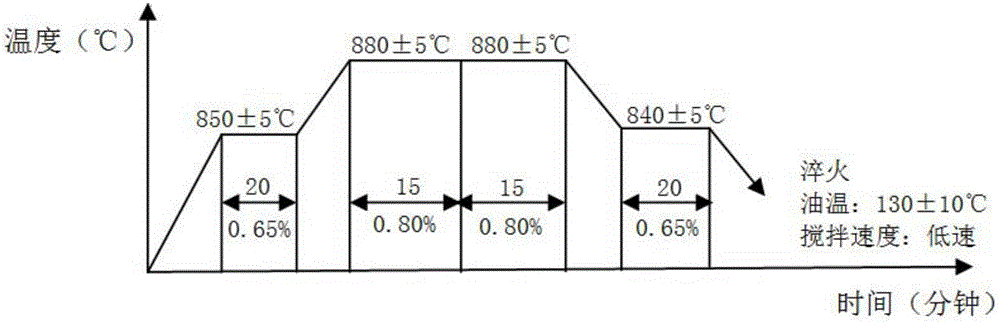

[0040] Taking the heat treatment process of a spiral bevel gear for a lawn mower with a modulus of 1.25 and a number of teeth of 13 as an example, the technical requirements for heat treatment are: surface hardness 600-700HV, effective hardened layer depth 0.2-0.4mm, tooth bar beating ≤ 0.015mm (runout of ribs before heat treatment ≤ 0.008mm), deformation of inner hole ≤ 0.015mm (deformation of inner hole before heat treatment ≤ 0.006mm). In order to meet the above heat treatment requirements, a heat treatment process for reducing the deformation of the spiral bevel gear for lawn mowers in this embodiment specifically includes the following steps:

[0041] (1) Parts preparation: The spiral bevel gear for lawn mowers is prepared by using the alloy steel billet of SCM415. deformation and cracking, while reducing the hardness of the material and improving the machinability of the billet; in this embodiment, the chemical composition of the SCM415 alloy steel billet is (JIS G4085-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com