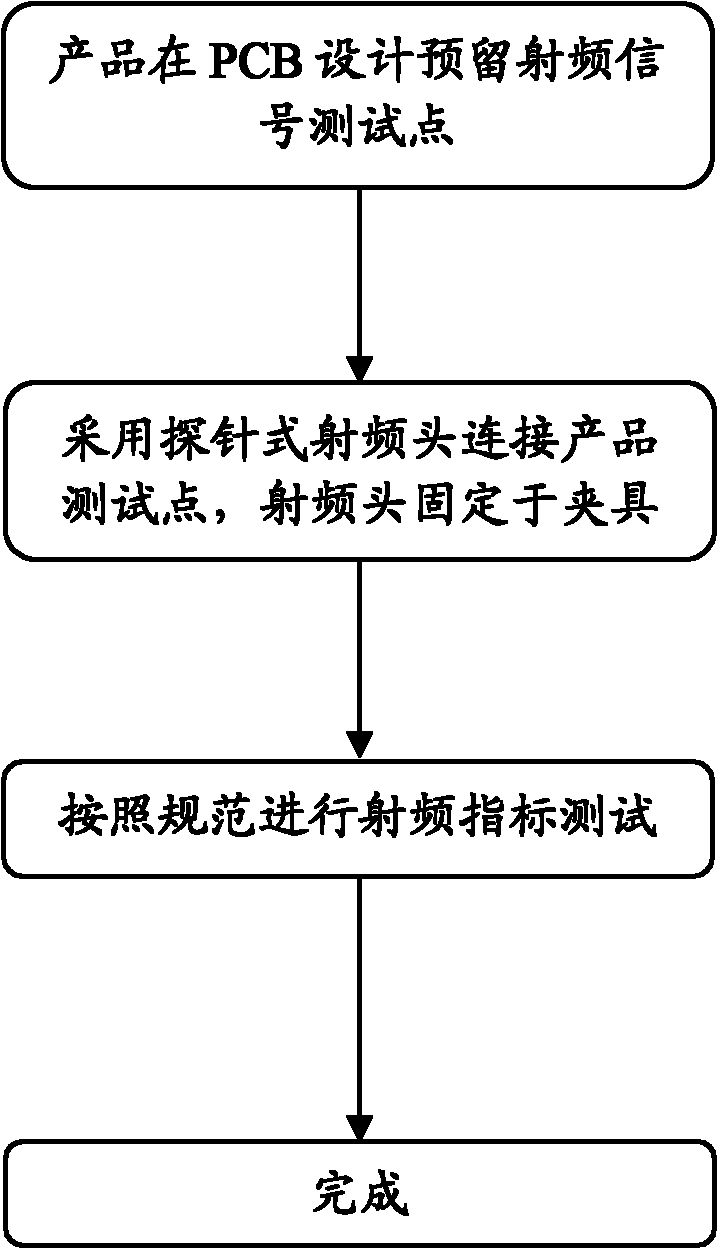

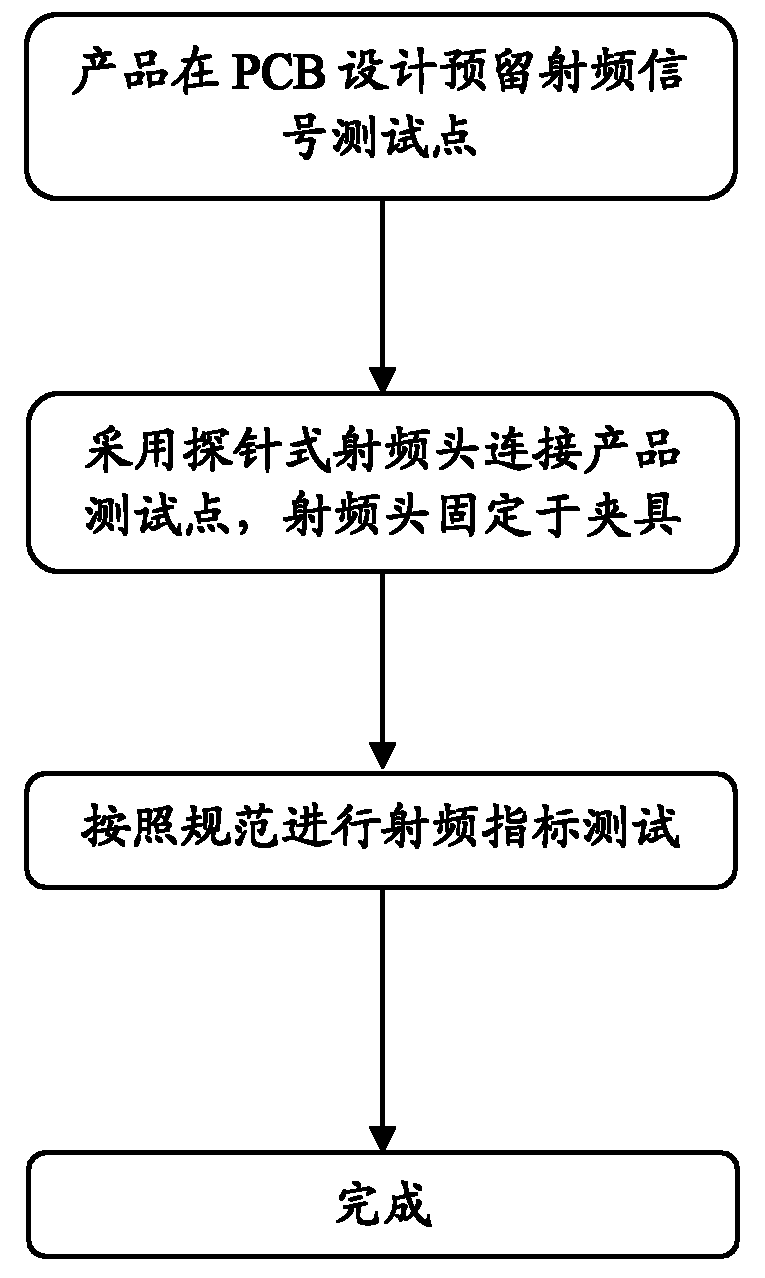

Radio-frequency (RF) signal test connection structure and radio-frequency signal test optimization method

A technology of radio frequency signal and test connection, which is applied in the field of radio frequency signal test and radio frequency communication. It can solve the problems of poor cooperation between the radio frequency head and the antenna connector, increase the cost of product materials, and the inability to customize the fixture test, etc., so as to improve the pass-through rate of the test. , high test efficiency, cost-saving effect of antenna connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0026] The radio frequency signal test connection structure includes a radio frequency test instrument, wherein a radio frequency signal test point is arranged on the product to be tested, and the radio frequency test instrument is connected with a probe type radio frequency head through a radio frequency cable, and the probe type The end probe of the radio frequency head is in contact with the radio frequency signal test point.

[0027] Wherein, the radio frequency signal test point is set on the opposite side of the antenna connector on the product under test, and the size of the radio frequency signal test point is the same as the contact surface size of the end probe of the probe type radio frequency head. Match, and the radio frequency signal test point is the radio frequency signal exposed copper part and the ground signal exposed coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com