Processing and assembling method for linear combined guide rail of box body

A technology of combining guide rails and assembly methods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low adjustment qualification rate, large workload, and difficulty in correcting deformation, etc., to improve dimensional accuracy and assembly qualification rate. The effect of improving and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

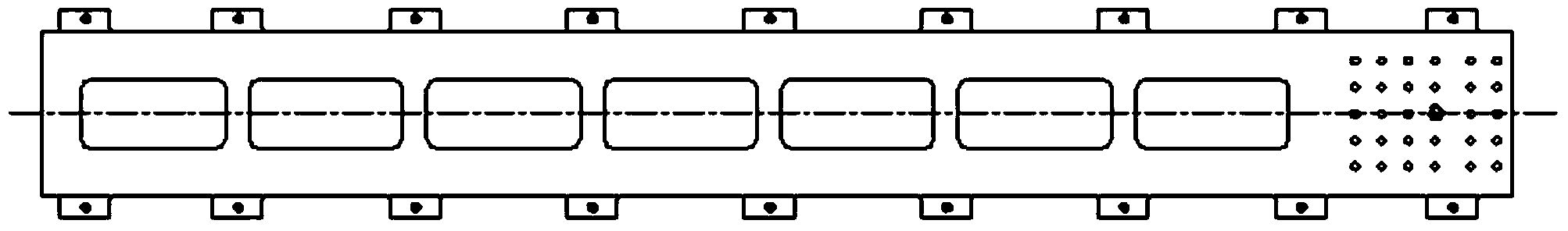

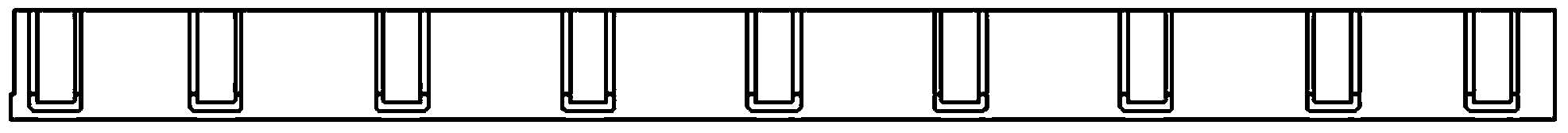

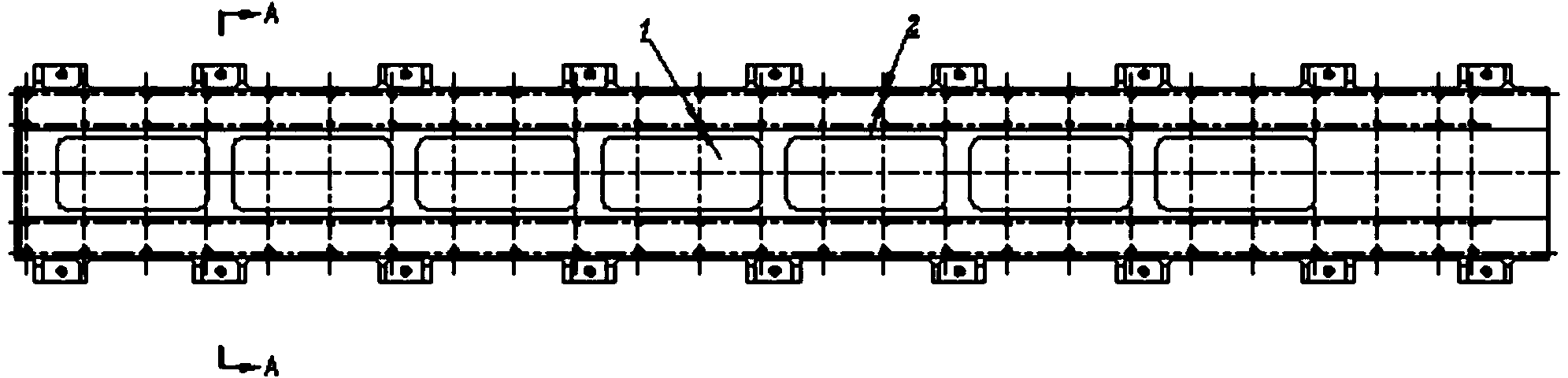

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0043] The invention improves the processing flow of each component (including the rear guide rail body and the left and right slide rails), reduces or controls the amount of denaturation; improves the processing and assembly process of the left and right slide rails, and reserves a processing allowance to be assembled to the rear guide rail body After the groove is processed to the design size; finally, the left and right beading is installed to ensure that the size of the working surface (chute) required by the design meets the requirements, specifically including the following steps:

[0044] 1) Processing of the rear guide rail body

[0045] Process flow of rear rail body processing:

[0046] Scribing and milling processing line—rough milling shape—artificial aging—fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com