Multi-tab size-variable high magnification lithium ion battery

A lithium-ion battery, variable size technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of increased processes, large internal resistance of the poles, and high production costs, and can increase the number of poles, The effect of low battery internal resistance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Production of positive electrode current collector: mix the positive electrode active material, conductive agent, binder and solvent according to a certain ratio, and add them into the mixing tank according to a certain amount and order and stir them evenly to prepare a positive electrode slurry with good fluidity and uniform dispersion. Then use a roller coating or extrusion spray coating machine to evenly coat the prepared positive electrode slurry on the aluminum foil, leaving blank space on both sides of the current collector to facilitate the subsequent production of multiple positive electrodes. The positive electrode slurry is prepared using nickel Lithium cobalt manganese oxide:conductive agent SP:KS-6:PVDF is 93:2.5:1.5:3 ratio processing slurry, solid content is 60-65%, double-sided coating surface density is 310-320g / m2.

[0027] The positive electrode active material mentioned in the present invention can be lithium manganate, lithium ferrous phosphate, lithi...

Embodiment 2

[0037] Because the manufacturing method of pole piece coating and cutting used in this example is the same as Example 1, it will not be described again.

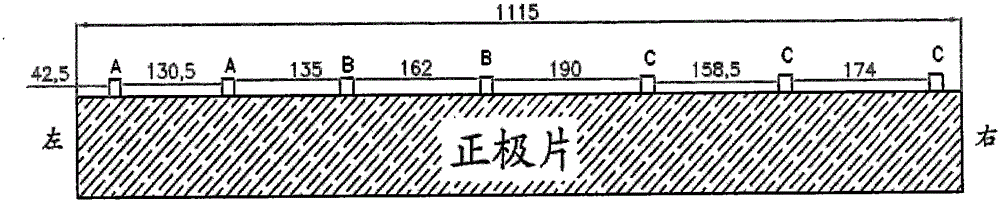

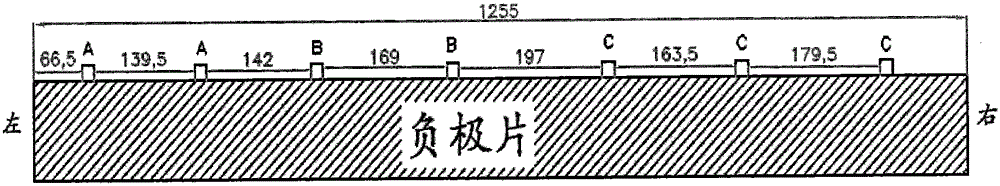

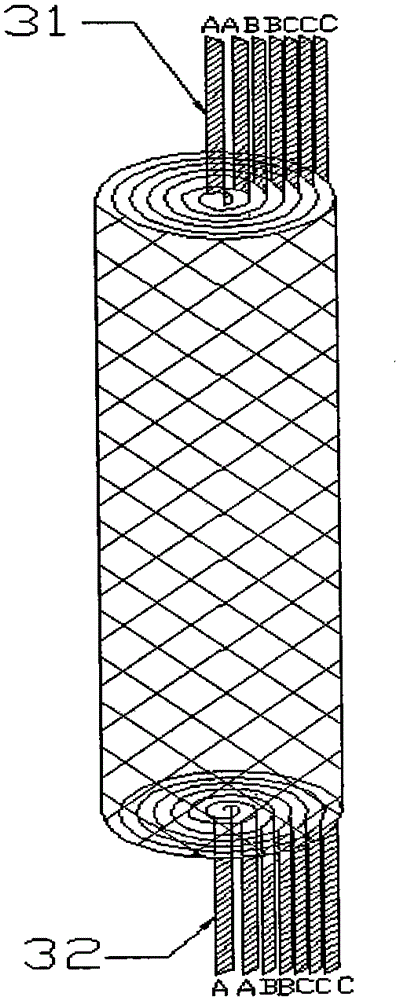

[0038] as attached Figure 4 And attached Figure 5 As shown, in this example, a plurality of lugs A, B, and C with different intervals and widths are set on the blank positions reserved for the positive and negative electrodes. Manufactured by punching or laser cutting. In this example, a square needle winding method is used to produce a square cell structure, and the tabs are on the same side, and the winding starts from the left side of the pole piece, and three different widths of tabs A, B and C are set. , the width of tab A is set to be 0.5-1.5mm larger than the width of tab B, and the width of tab B is 0.5-1.5mm larger than the width of tab C. The present invention is an example of a 5Ah battery, so the process of the integrated battery For the current capacity, the width of the A tab is 13mm, the width of the B ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com