Automatic wet process lamination method of rigid printed circuit boards

A printed circuit board and wet film laminating technology, which is applied in the secondary treatment of printed circuits, coating of non-metallic protective layers, etc., can solve problems such as graphic defects, copper surface oxidation, etc., achieve circuit integrity, protect copper surface, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The steps of the automatic wet film laminating process for printed circuit boards are as follows:

[0020] a. Accurately weigh 100 grams of water and 1.5 grams of MEK butanone, mix and heat to 55°C;

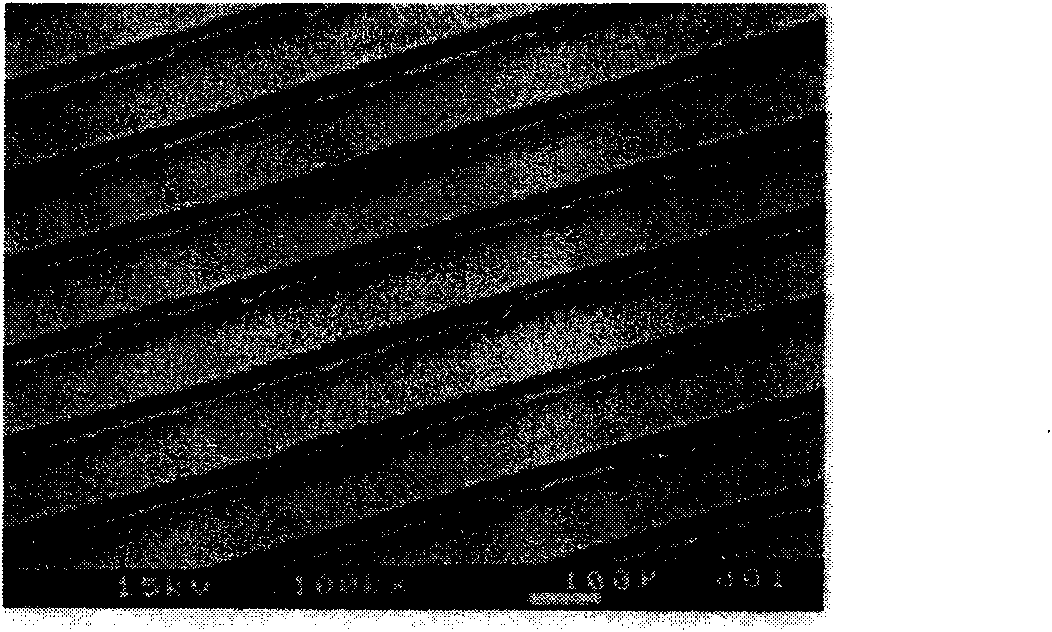

[0021] b. Mechanically brush and chemically roughen the base material of the rigid circuit board. After drying, preheat it with a preheating machine at a preheating temperature of 50°C;

[0022] c. Add the prepared mixture to the sponge roller, and pass the pre-treated substrate through two pairs of sponge rollers, and evenly coat a layer of liquid film on the copper surface;

[0023] d. After the substrate coated with water film passes through an automatic film laminating machine with a temperature of 100°C, a pressure of 4KG, and a film laminating speed of 3m / min, the dry film is tightly attached to the copper surface substrate.

Embodiment 2

[0025] a. Accurately weigh 100 grams of water and 0.1 gram of carboxybenzotriazole, mix and heat to 50°C;

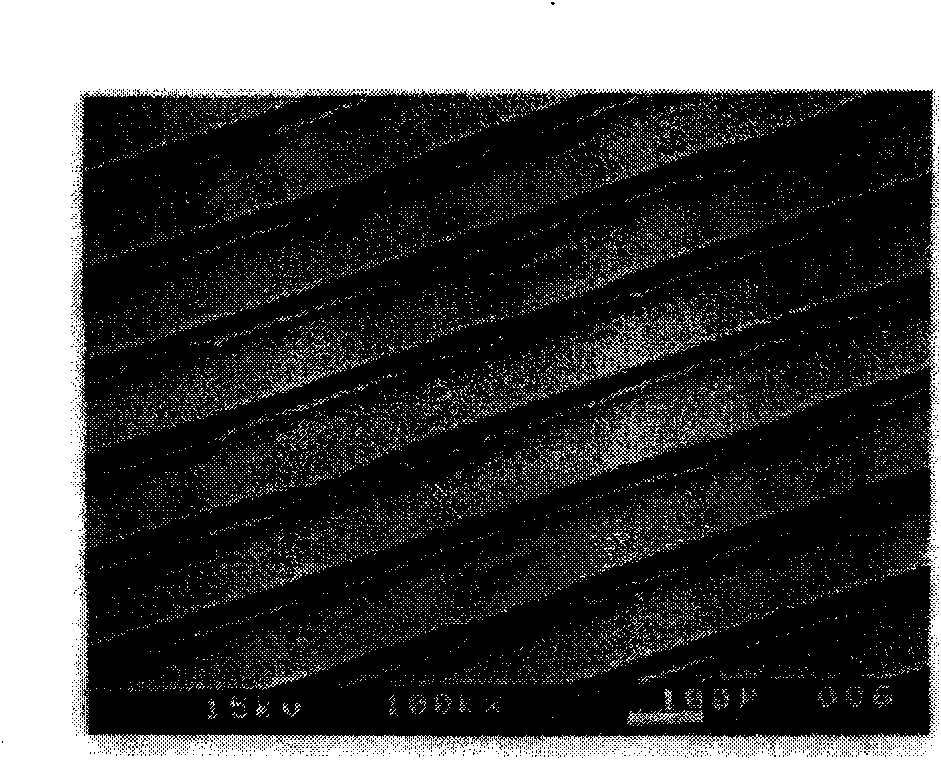

[0026] b. Mechanically brush and chemically roughen the base material of the rigid circuit board. After drying, preheat it with a preheating machine at a preheating temperature of 50°C;

[0027] c. Add the prepared mixture to the sponge roller, and pass the pre-treated substrate through two pairs of sponge rollers, and evenly coat a layer of liquid film on the copper surface;

[0028] d. Pass the substrate coated with the water film through an automatic film laminating machine with a temperature of 100°C, a pressure of 3.5KG, and a film laminating speed of 1.5m / min, and then the dry film is tightly attached to the copper surface substrate.

Embodiment 3

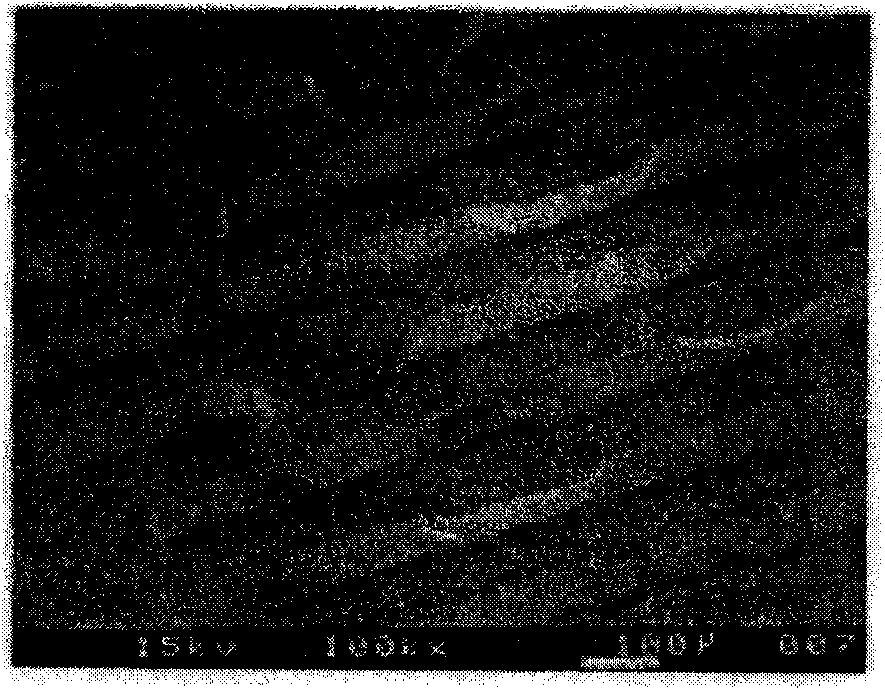

[0030] a. Accurately weigh 100 grams of water and 0.5 grams of 2-ethylhexanol, mix and heat to 55°C;

[0031] b. Mechanically brush and chemically roughen the base material of the rigid circuit board. After drying, preheat it with a preheating machine at a preheating temperature of 50°C;

[0032] c. Add the prepared mixture to the sponge roller, and pass the pre-treated substrate through two pairs of sponge rollers, and evenly coat a layer of liquid film on the copper surface;

[0033] d. Pass the substrate coated with the water film through an automatic film laminating machine with a temperature of 80°C, a pressure of 4KG, and a film lamination speed of 2m / min, and then attach the dry film tightly to the copper surface substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com