Method for welding door frame of ultra-low-temperature high-power wind turbine tower

A technology of wind power tower and welding method, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of difficult welding, difficult quality assurance, unqualified tower flange flatness and ovality, etc. It is beneficial to achieve anti-fatigue performance and anti-stress corrosion performance, eliminate residual tensile stress on the surface, and improve the first pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

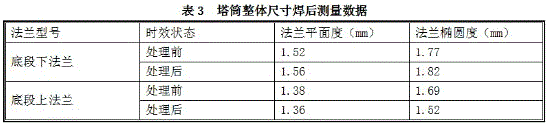

Examples

Embodiment Construction

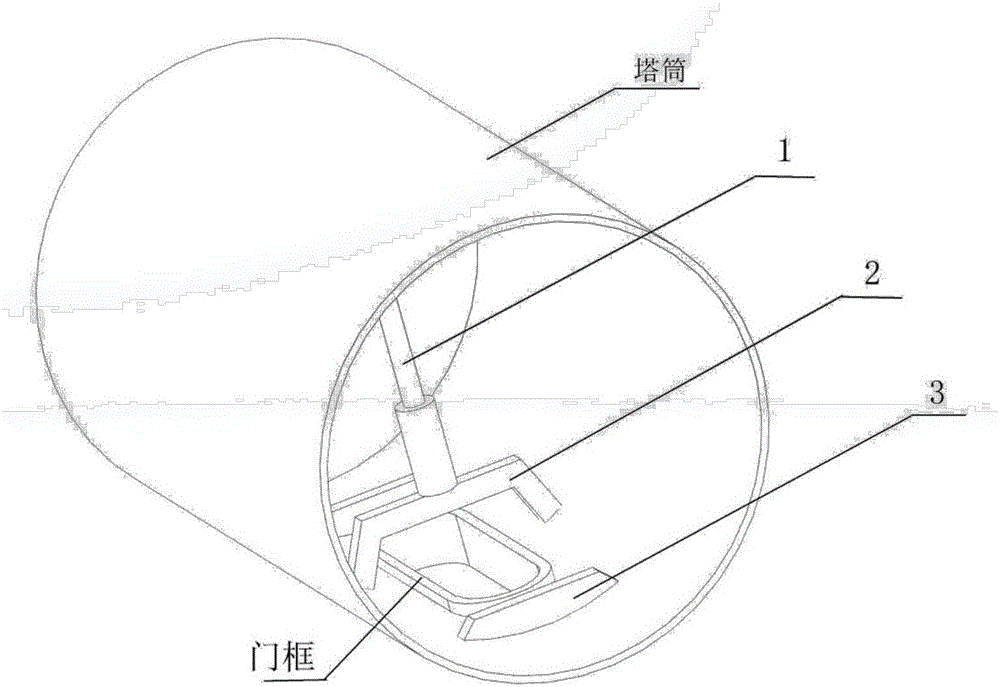

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

[0032] The invention discloses a method for welding a door frame of an ultra-low temperature and high-power wind power tower, comprising the following steps:

[0033] (1) Door frame material preparation: The door frame material preparation is prepared by splicing two parts. The unloaded steel plate is rolled into shape by a plate rolling machine. Stress concentration is not avoided. The splicing seams are located on both sides of the door frame center line. 150mm, control the flame heating range, reduce the influence of the metallographic structure of the cutting plate, assemble and weld the two formed door frames; or use thick plates to cut and blank the whole by CNC programming;

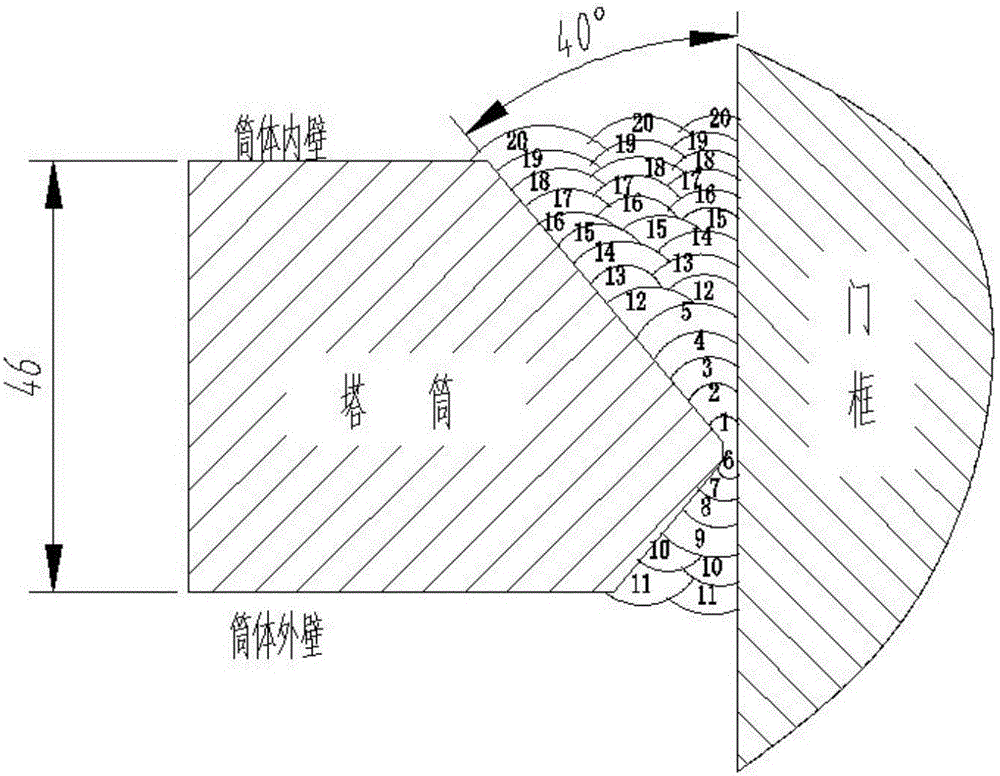

[0034] (2) Door opening cutting: Before cutting the door opening, adjust the installation axis of the tower tube to the basic horizontal state, use the door frame as a physical template, draw a lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com