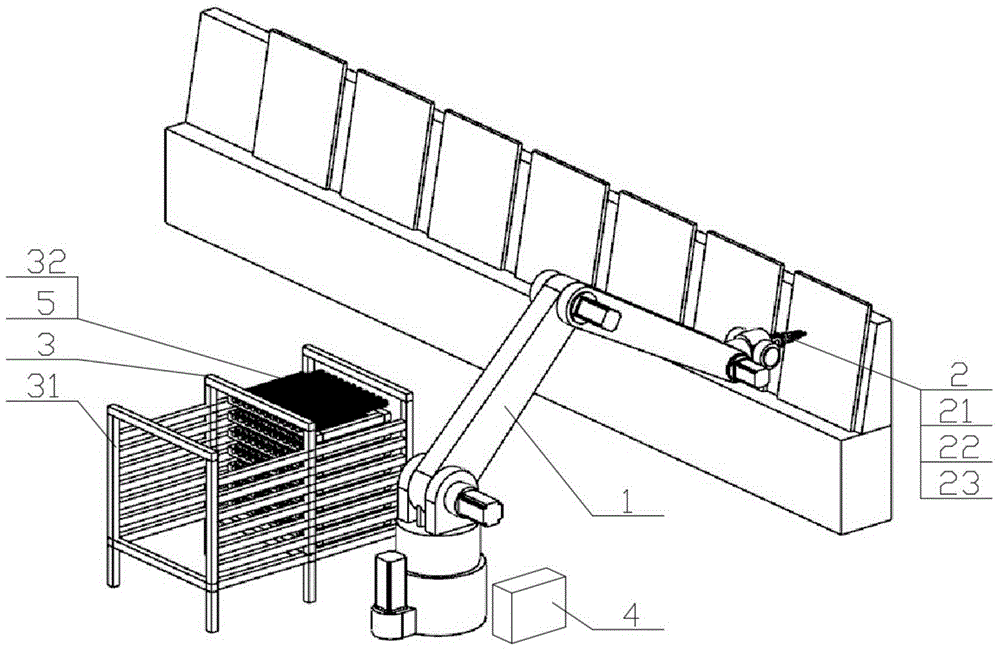

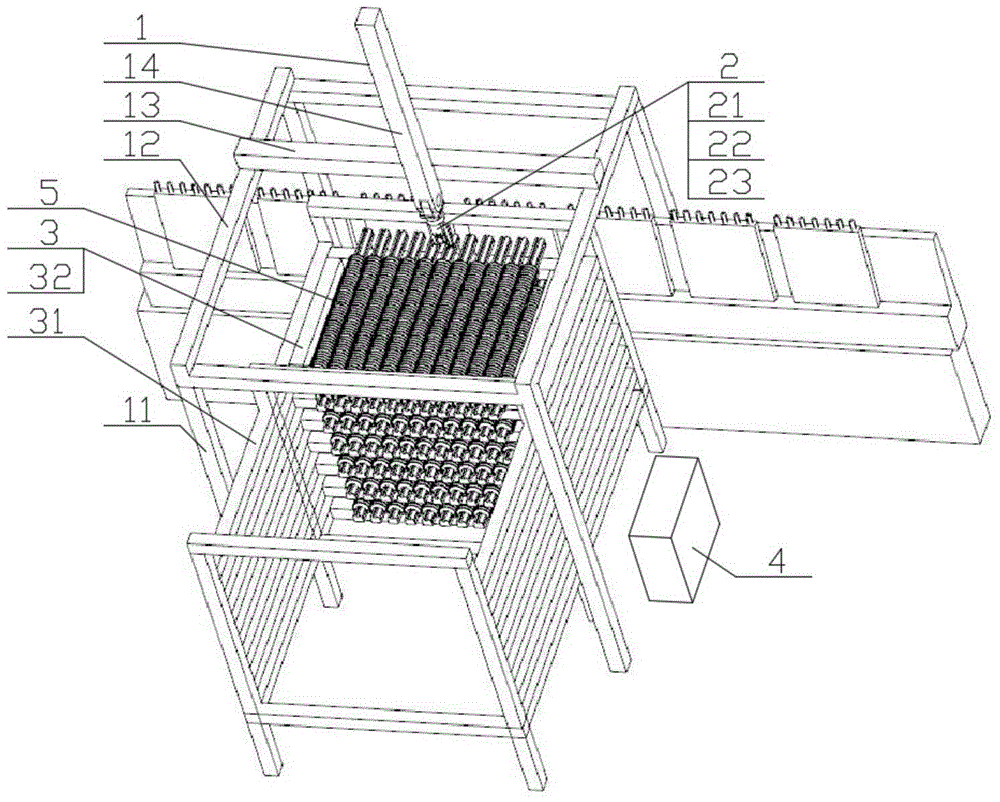

Digital-bus-based automatic small-U-shaped-pipe inserting system of fin assembly

A digital bus, U-shaped tube technology, applied in the field of air-conditioning manufacturing, can solve the problems of high labor intensity of operators, stop work waiting for materials, low equipment utilization rate, etc., achieve high equipment automation, prevent quality accidents, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

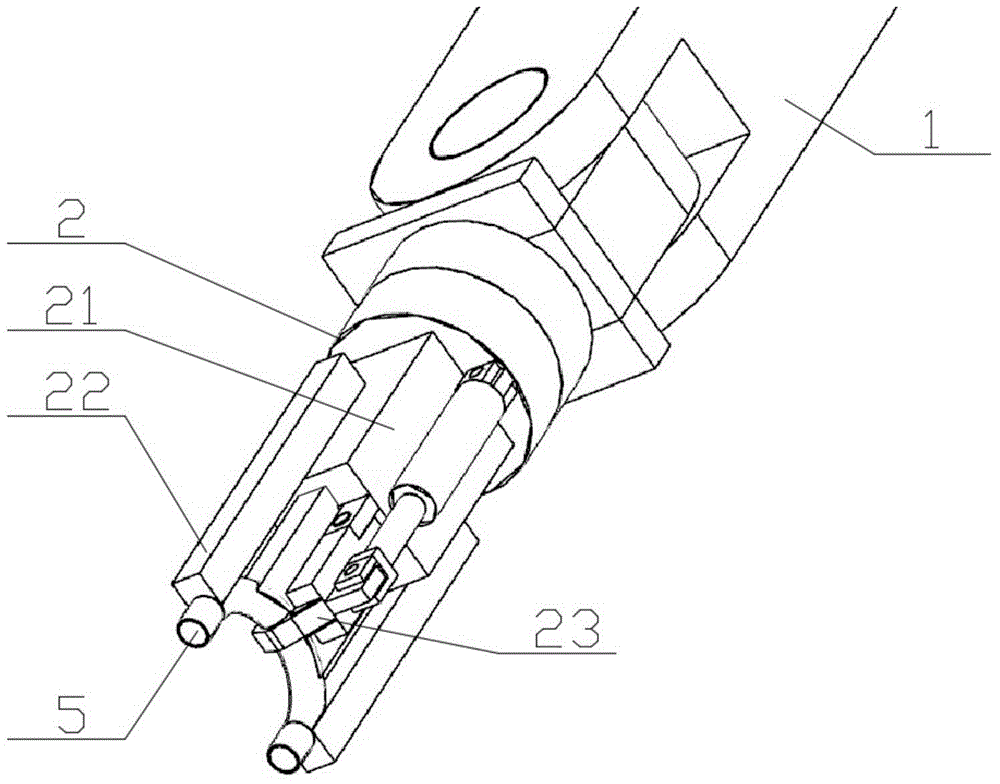

[0066] As an embodiment of the lifting finger 23 of the present invention, the lifting finger 23 is L-shaped, its top end is hingedly connected to the body 21, one end of the transmission connection mechanism is connected to the body 21, and the other end is connected to the L-shaped lifting finger. On the finger 23, the industrial control computer can realize the L-shaped holding finger 23 to engage or separate from the bottom end of the body 21 by controlling the transmission and connection mechanism of the holding finger 23 to rotate along its hinge axis.

[0067] As another embodiment of the lifting finger 23 of the present invention, the lifting finger 23 is in a horizontal U shape, and one end of the horizontal U shape penetrates into the body 21 along the vertical direction, and the transmission connection of the lifting finger 23 The mechanism is arranged parallel to the horizontal U-shaped support finger 23, one end of the transmission connection mechanism is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com