Corrugated board production line real-time monitoring method

A corrugated cardboard, real-time monitoring technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of no monitoring and management, inability to predict in advance, inaccurate data, etc., to prevent any quality accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The real-time monitoring method adopted in the present invention is suitable for production lines of corrugated cardboard with any number of layers, including three-layer, five-layer, seven-layer and other corrugated cardboard production lines. The method of the present invention will be described in more detail below through specific examples.

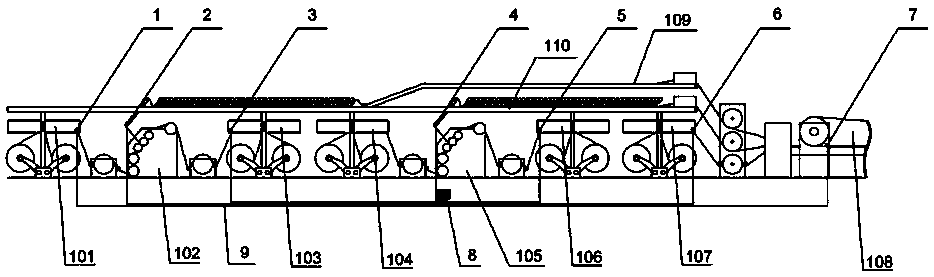

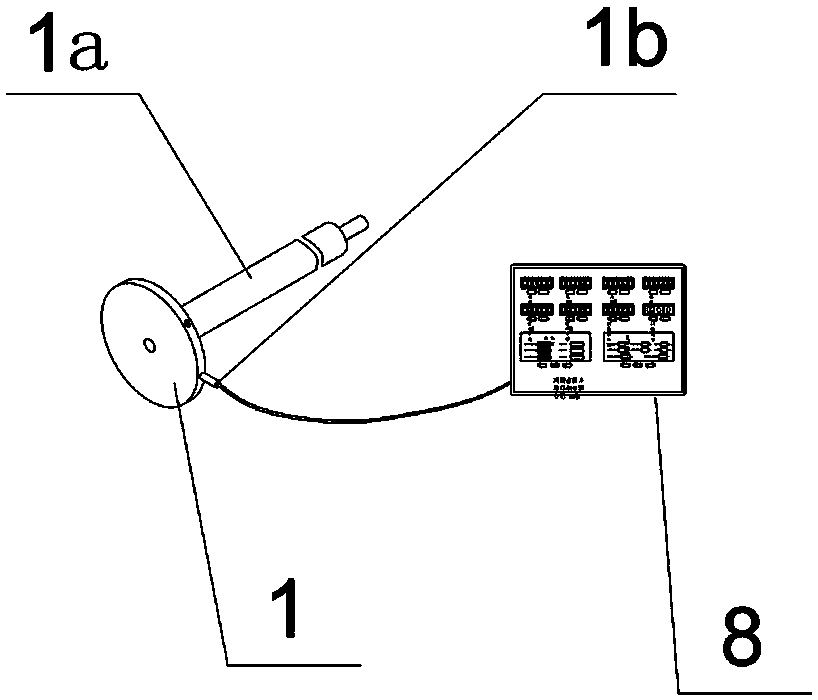

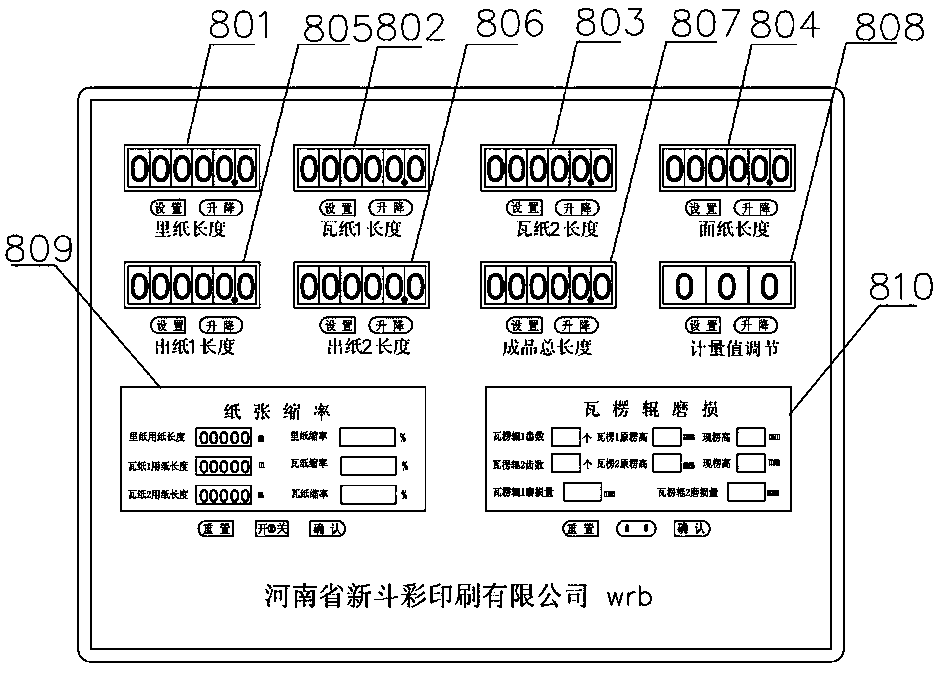

[0018] figure 1 It is the main equipment layout of the five-layer corrugated cardboard production line, including two corrugated main machines, two corrugated paper racks, one inner paper rack, one sandwich paper rack, one face paper rack and one drying tunnel ( Front end part), the arrangement sequence is lining paper frame 101, first corrugated paper frame 102, first corrugated paper frame 103, sandwich paper frame 104, second corrugated paper frame 105, second corrugated paper frame 106, surface Paper rack 107 and drying tunnel 108; semi-finished paper conveying bridges 109 and 110 are respectively set above the first corru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com