Polystyrene foam recovery regeneration buffer packing gasket and production method thereof

A foamed plastic and polystyrene technology, applied in the field of packaging materials, can solve the problems of non-natural degradation of packaging waste, limited buffer performance and strength, energy and resource crisis, etc., to promote the development of circular economy, excellent buffer performance, and social benefits. considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

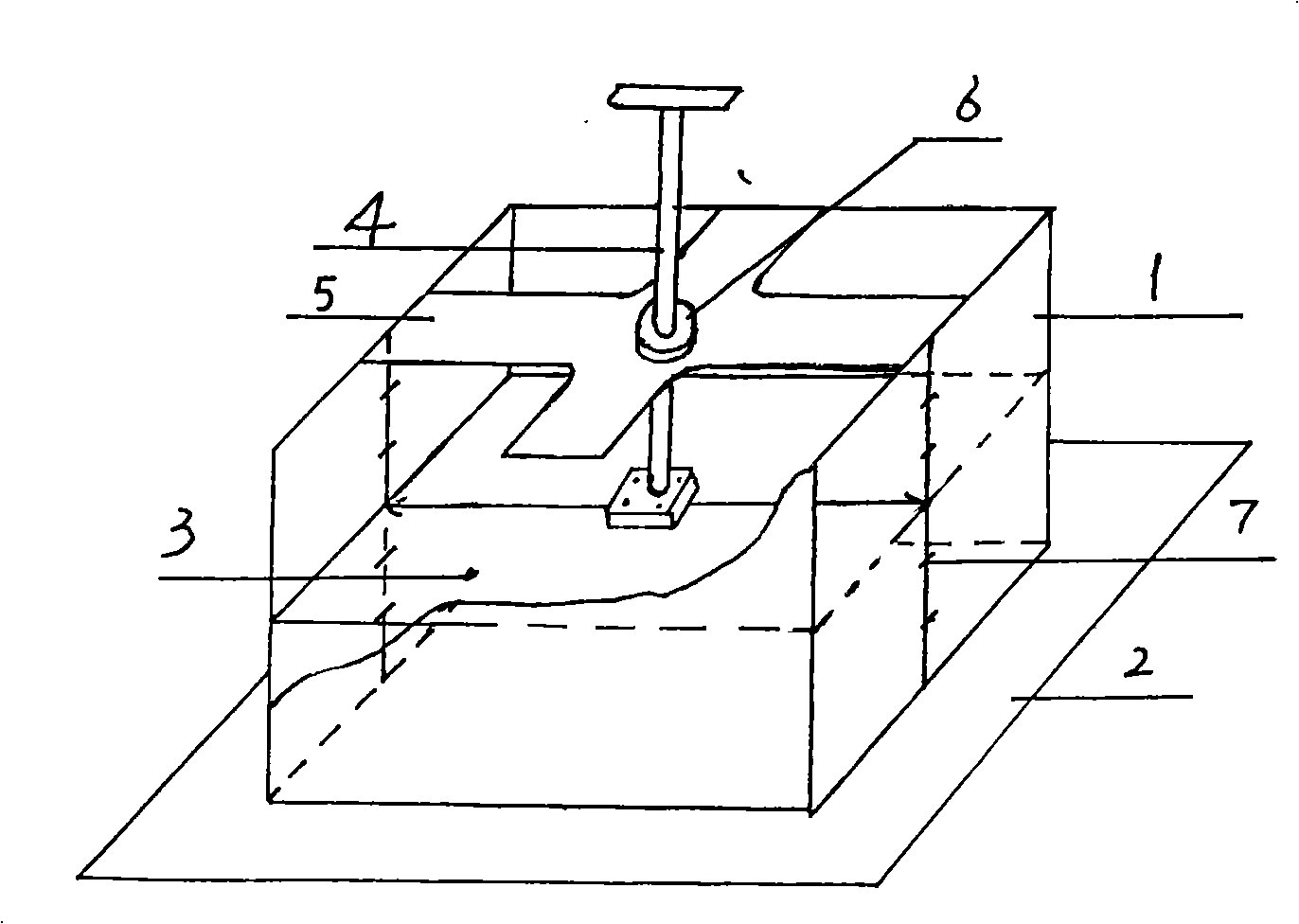

[0016] Further detailed explanation in conjunction with accompanying drawing:

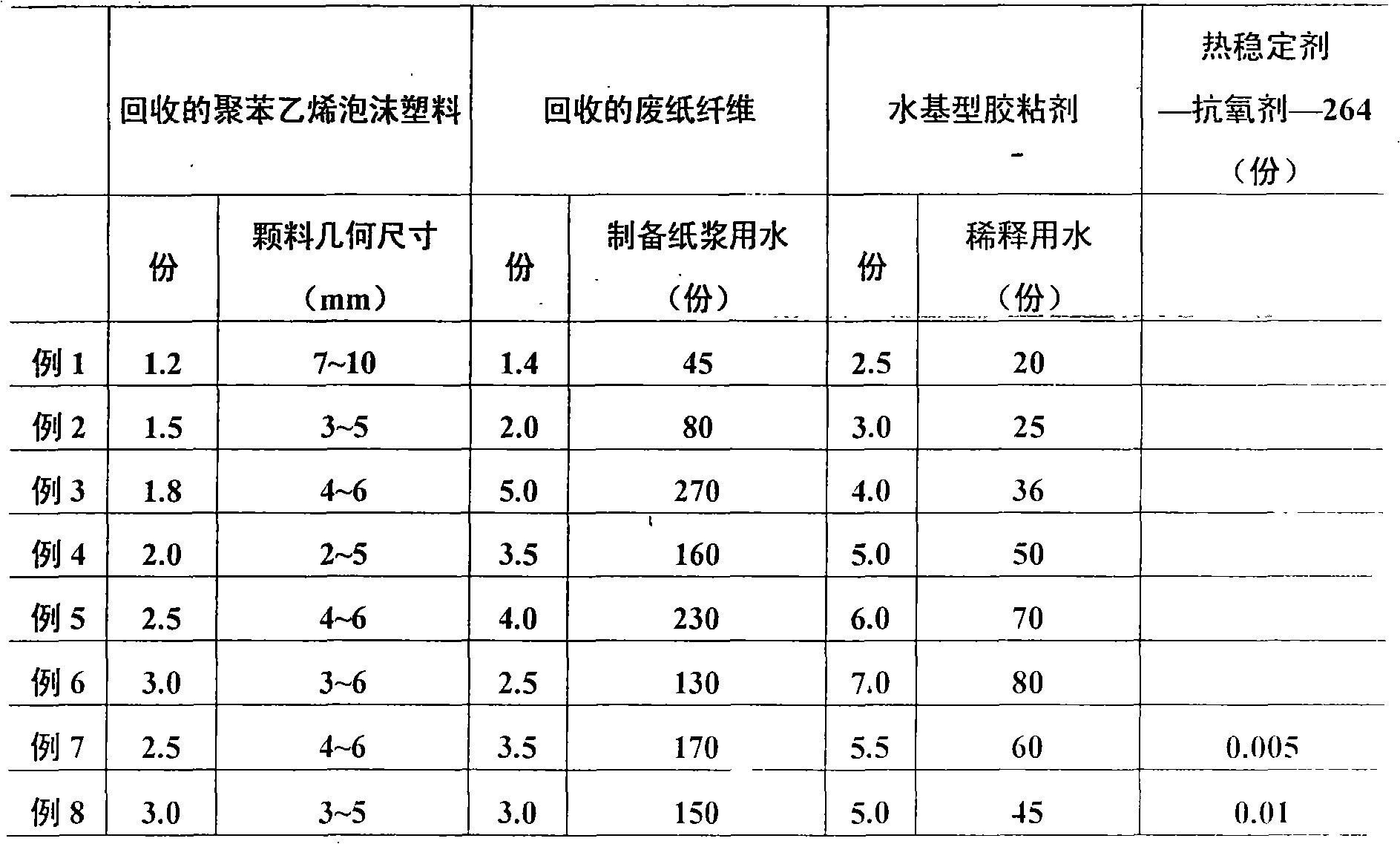

[0017] A. Regarding polystyrene foam recycling and recycled cushioning packaging liners, the components and their mass / part ratios are as follows:

[0018] The mass fraction of the recovered polystyrene foam is 1-3 parts, and the geometric size of the particles made by mechanical crushing is 2-10 mm, preferably 4-6 mm.

[0019] Recycled waste paper fiber—that is, the mass fraction of waste paper is 1 to 5 parts, and the mass fraction ratio of the waste paper to water is 1:30 to 60, preferably 1:45 to 55. Paper fiber pulp; waste paper can be all kinds of waste paper, books, newspapers, cardboard, etc., but does not contain non-paper debris, otherwise it needs to be removed;

[0020] The mass fraction of the water-based adhesive is 2 to 7 parts, and the mass fraction ratio of the water-based adhesive is 1:8-12 by adding water for dilution; the water-based adhesive should be an environmentally friend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com