Full-automatic rail positioning box filling machine

A cartoning machine, fully automatic technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problem that the opening and closing angle of the carton cannot fully meet the packaging requirements, the maximum operating speed of the equipment is limited, and the transmission parts are prone to failure. , to achieve the effect of improving the operating performance of the equipment, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

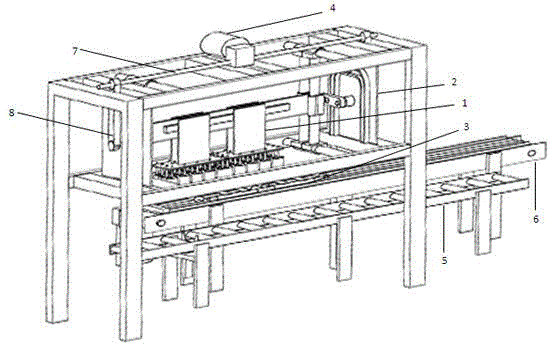

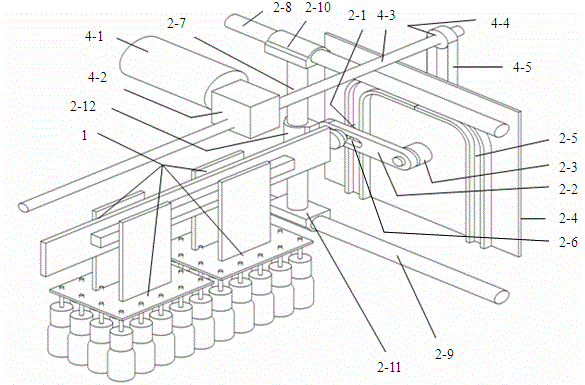

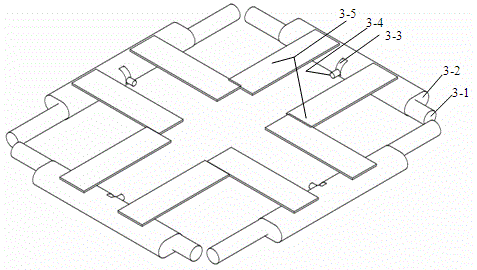

[0039] The invention relates to a simple, quick and accurate automatic track positioning packing machine. Such as figure 1 As shown, it consists of a box packing mechanism 1, two sets of positioning mechanisms 2, at least one set of unpacking mechanisms 3, a power source 4, a roller conveyor 5, a bottle conveyor 6, a power transmission mechanism 7, and two sets of synchronization mechanisms 8.

[0040] Two sets of positioning mechanisms 2 are respectively fixedly arranged on the left and right sides of the box packing machine. Positioning tracks are arranged on the positioning mechanism 2. The box packing mechanism 1 is located in the middle of the two sets of positioning mechanisms 2. The positioning mechanism 2 drives the transmission under the action of the power source. The packing mechanism 1 carries out the packing operation according to the path determined by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com