Optical transducer packaging structure and optical sensing module

A light-sensing module and packaging structure technology, applied in radiation control devices, TVs, color TV components, etc., can solve the problems of glue material flowing to the surface of light-sensing chips, high packaging accuracy requirements, and difficulty in manufacturing. , to avoid overflow to the surface of the light sensor chip, the production yield and quality are stable, and the area and volume are reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

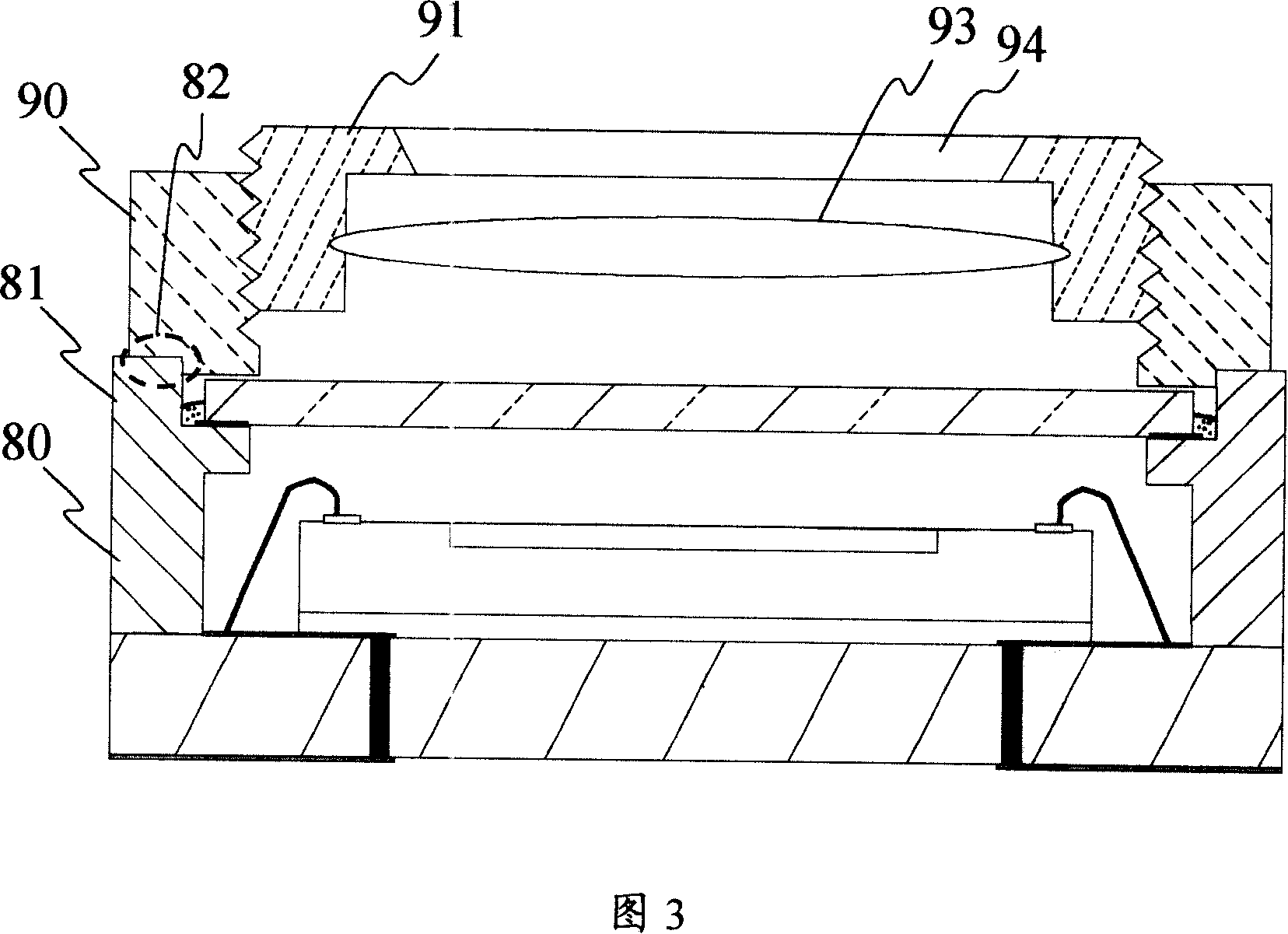

[0033] As shown in FIG. 2 , it is a schematic diagram of the package structure of the light sensor provided by the embodiment of the present invention. The light sensor packaging structure is mainly composed of a substrate 50 , a light sensing chip 60 , a frame 80 and a transparent layer 70 .

[0034] Wherein, the material of the substrate 50 can be BT (Bismaleimide Triazine) resin, FR5 resin or ceramic material, and several metal wirings 51 are arranged on the upper surface and the lower surface of the substrate 50, and these metal wirings 51 are plated through holes passing through the substrate 50. 52 are electrically connected. The light-sensing chip 60 is adhered to the upper surface of the substrate 50 through the adhesive layer 54, and has a light-sensing area 62 on its surface, and is connected to the metal wiring 51 with the metal wire 72 through the wire bonding method, and is formed with the substrate 50. electrical connection. The light-transmitting layer 70 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com