Photocuring liquid adhesive film composition and application thereof

A liquid adhesive film and light-curing technology, which is applied in the direction of film/sheet without carrier, adhesive, photovoltaic power generation, etc., can solve the problem that the lamination curing time cannot be greatly reduced, the production cycle and cost are increased, and the adhesive film and glass are bonded Insufficiency and other problems, to achieve the effect of shortening the production cycle, improving production efficiency, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

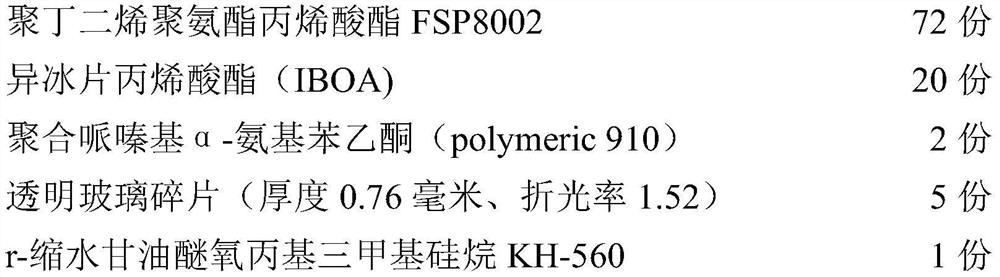

[0055] The formula of photocurable liquid adhesive film is:

[0056]

[0057] Glass shards production method: wash and dry glass with a thickness of 0.76 mm, crush and sieve to obtain glass particles with a particle size of 1-2 mm and a thickness of 0.76 mm.

[0058] Stir the components in the above formula evenly, vacuum defoam to obtain a light-curable liquid film composition, the refractive index is 1.518, preheat to 60°C, first apply the first layer of light-curable liquid film composition on the surface of the glass panel, The thickness of the coating is 0.76 mm. After laying the battery layer, apply the second layer of light-curable liquid adhesive film composition on the surface of the battery layer. The coating thickness is 0.76 mm, covering the glass back plate. After vacuum defoaming, UV light curing, the irradiation time is 110 seconds, irradiation energy 1800mj / cm 2 , get the packaged glass, install the leads and the frame to get the photovoltaic module.

Embodiment 2

[0060] The formula of photocurable liquid adhesive film is:

[0061]

[0062] Stir the components in the above formula evenly, and vacuum defoam to obtain a photocurable liquid film composition. The refractive index is 1.51. Preheat to 60°C. First, apply the first layer of photocurable liquid film composition on the surface of the glass panel. The thickness of the coating is 1.5 mm. After laying the battery layer, apply the second layer of light-curable liquid adhesive film composition on the surface of the battery layer. The coating thickness is 1.5 mm. Cover the glass back plate. Under the environment, the radiation energy is 250eV, and the packaged golden power generation glass is obtained, and the lead wire and frame are installed to obtain the photovoltaic module.

Embodiment 3

[0064] The formula of photocurable liquid adhesive film is:

[0065]

[0066] Stir the components in the above formula evenly, and vacuum defoam to obtain a photocurable liquid film composition with a refractive index of 1.52. Preheat to 60°C for coating. First, apply the first layer of photocurable liquid film composition on the glass On the surface of the panel, the thickness of the coating is 0.38 mm. After laying the battery layer, apply the second layer of photocurable liquid adhesive film composition on the surface of the battery layer. The thickness of the coating is 0.38 mm. , irradiation time 80 seconds, irradiation energy 1300mj / cm 2 , get the packaged power generation glass, install the leads and the frame to get the photovoltaic module.

[0067] Transparent photocurable resin particle D038 production method: the photocurable liquid film composition of Example 3 is coated into a film with a thickness of 0.38, and after vacuum defoaming, UV photocuring and photoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com