Programmed switch type temperature difference engine

A program-controlled switch and switch-type technology, which is applied in the direction of closed gas positive displacement engine factories, machines/engines, mechanical equipment, etc., can solve the problem that the maximum power is less than 200, the heat exchange capacity is limited, and it is difficult to make high power, etc. Problems, achieve high power output, improve energy utilization efficiency, and reduce the cost of solar power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

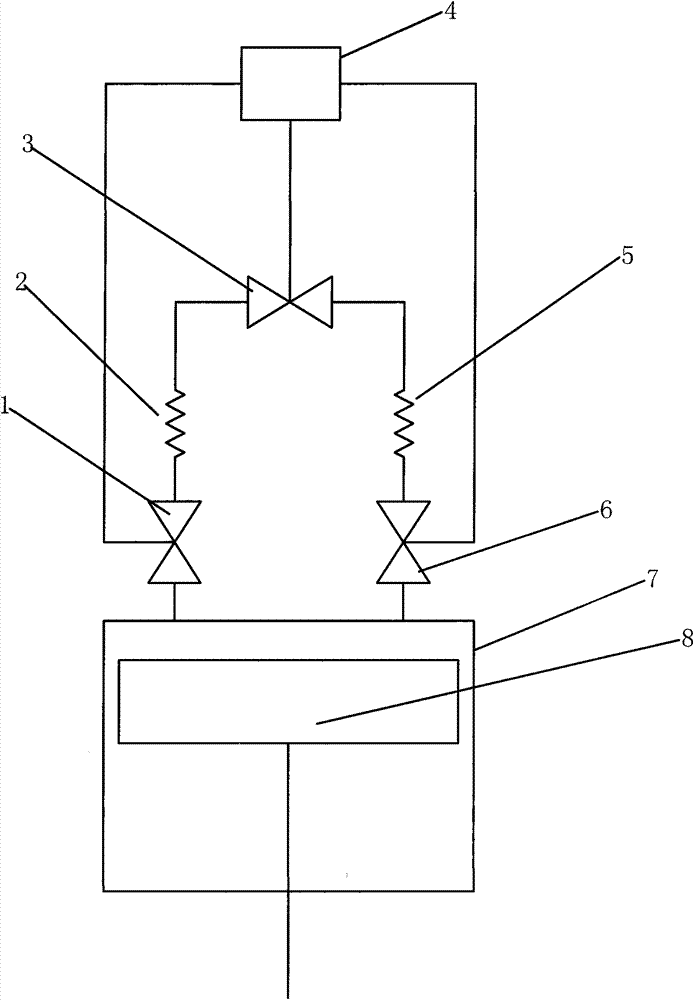

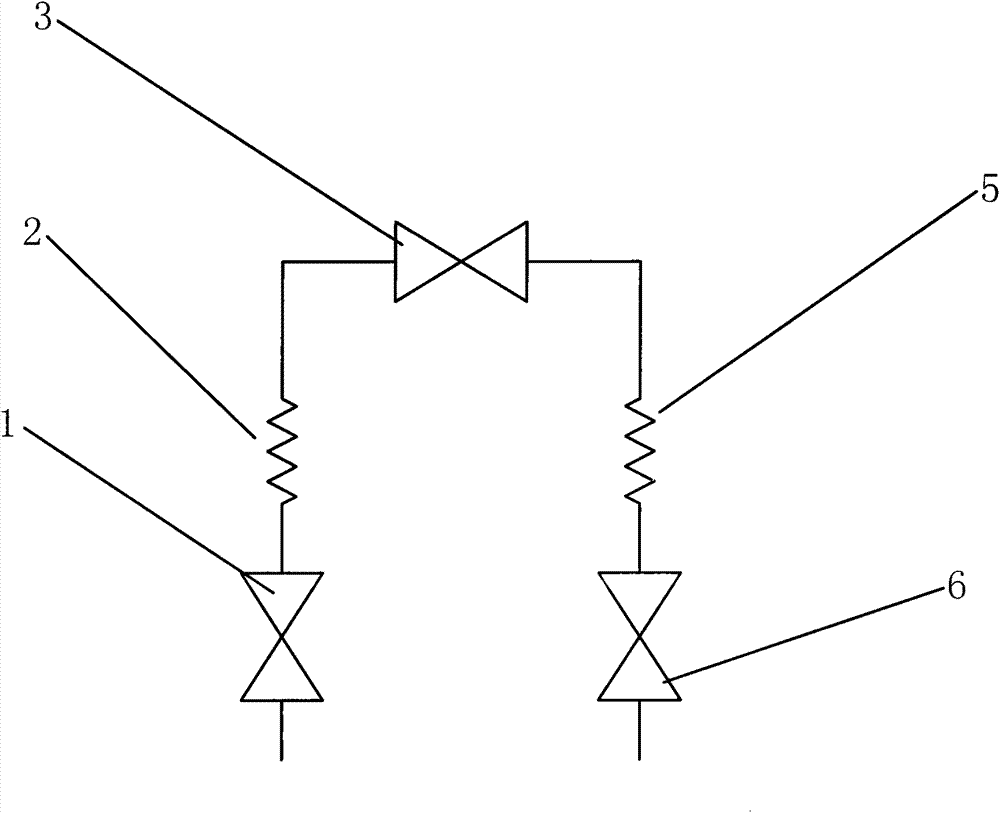

[0026] Embodiment one: see Figure 1-Figure 3 , a program-controlled switch-type thermoelectric engine, including an ECU, a switch-type heat exchange device combination, and a dedicated air motor. One end of the heater is connected to the air inlet of the special air motor through the outlet valve, one end of the cooler is connected to the air outlet of the special air motor through the inlet valve, and the other end of the heater and the cooler are connected together through the exchange valve.

[0027] The intake valve, the exhaust valve and the ventilation valve in the switch type heat exchange device combination are solenoid valves controlled by the ECU.

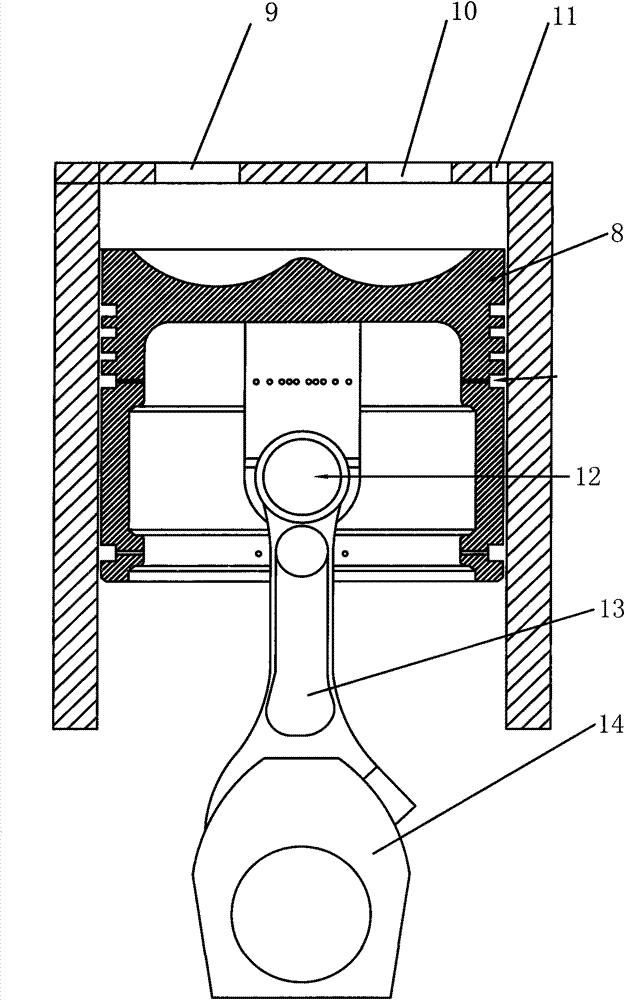

[0028] A kind of described special-purpose air motor is a piston type air motor, comprising a cylinder, a piston, a piston pin, a connecting rod, a crankshaft, a cylinder cover, an air inlet and an air outlet arranged on the cylinder cover, and the cylinder cover is provided with The switch type heat exchange device com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com