A paint packaging machine

A packaging machine and coating technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of unstable weight of the finished product of coating packaging, affecting the outlet flow rate, and unstable weighing, etc., and achieves small weight deviation of the finished product and smooth packaging. The effect of stable flow rate and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

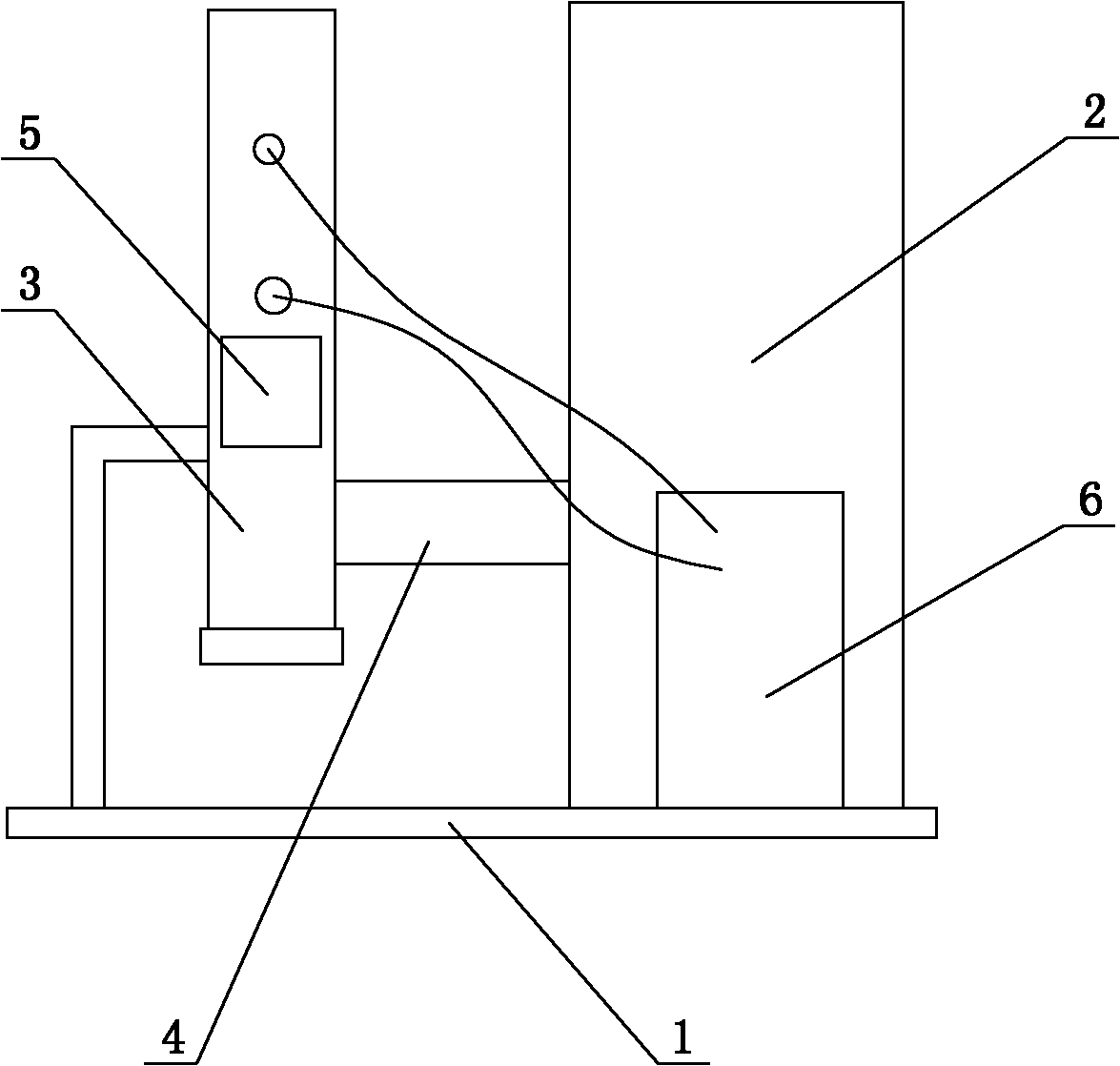

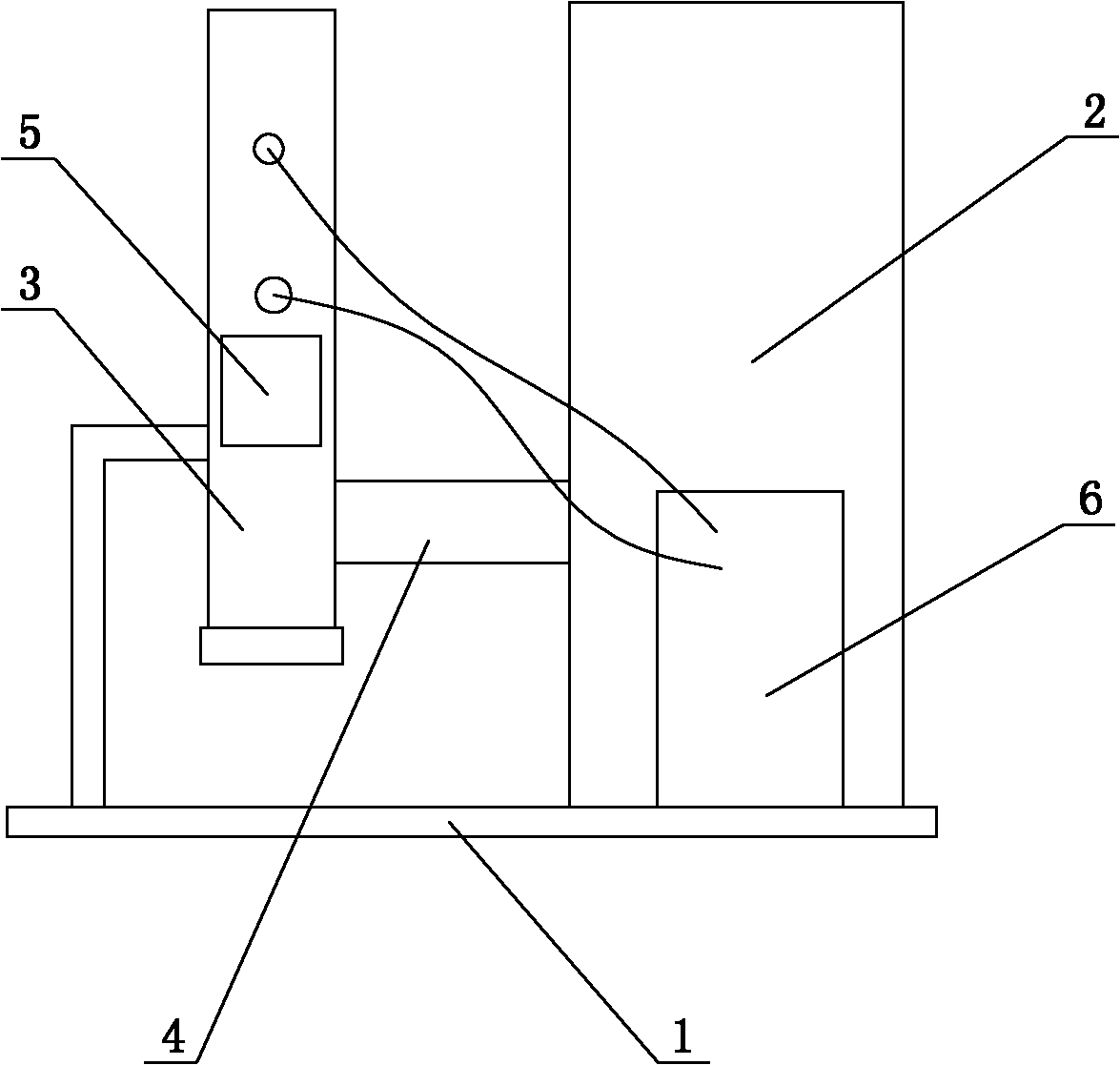

[0009] Such as figure 1 As shown, a paint packaging machine includes a frame 1, a filter set on the frame 1, a packaging outlet 3 set on the frame 1, and a communication tube is passed between the filter 2 and the packaging outlet 3 4 is connected, the packaging outlet 3 is provided with a pneumatic valve 5. The frame 1 is provided with an air cylinder 6 connected with a pneumatic valve 5. The air cylinder 6 acts on the pneumatic valve 5 to stabilize the packaging flow rate of the paint and ensure the accuracy of the finished product weight of the paint packaging, so that the weight deviation of the finished product is small. At the same time, pressure can be directly applied at the packaging outlet 3 to increase the packaging flow rate of the paint. The previous 1.5 kg per second has been increased to 2.5 kg per second, which improves packaging efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com