Cavity casting and liner removing technique

A process and cavity technology, which is applied in the field of cavity casting and de-billing process, can solve the problems of increased cost, weight deviation, unqualified parts performance, etc., and achieves the effects of good cost, small weight deviation and cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

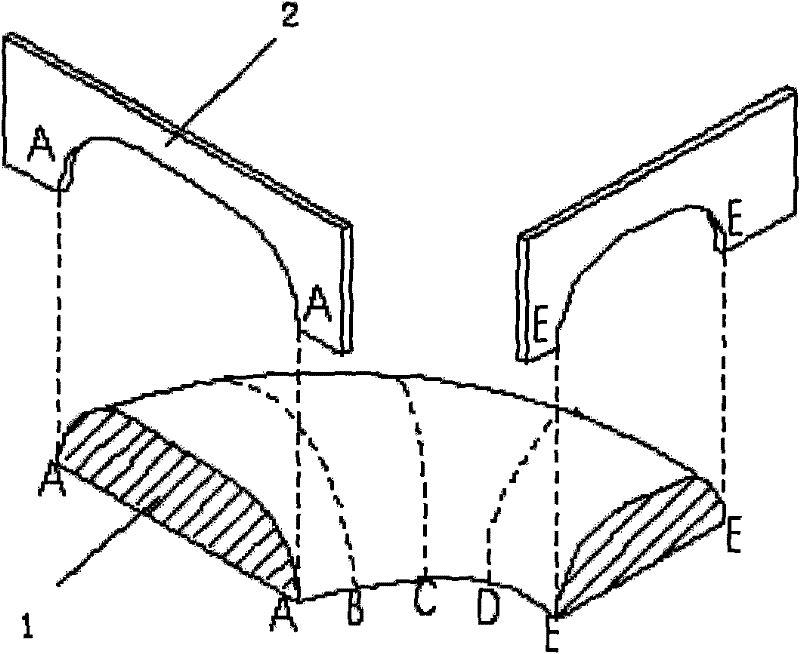

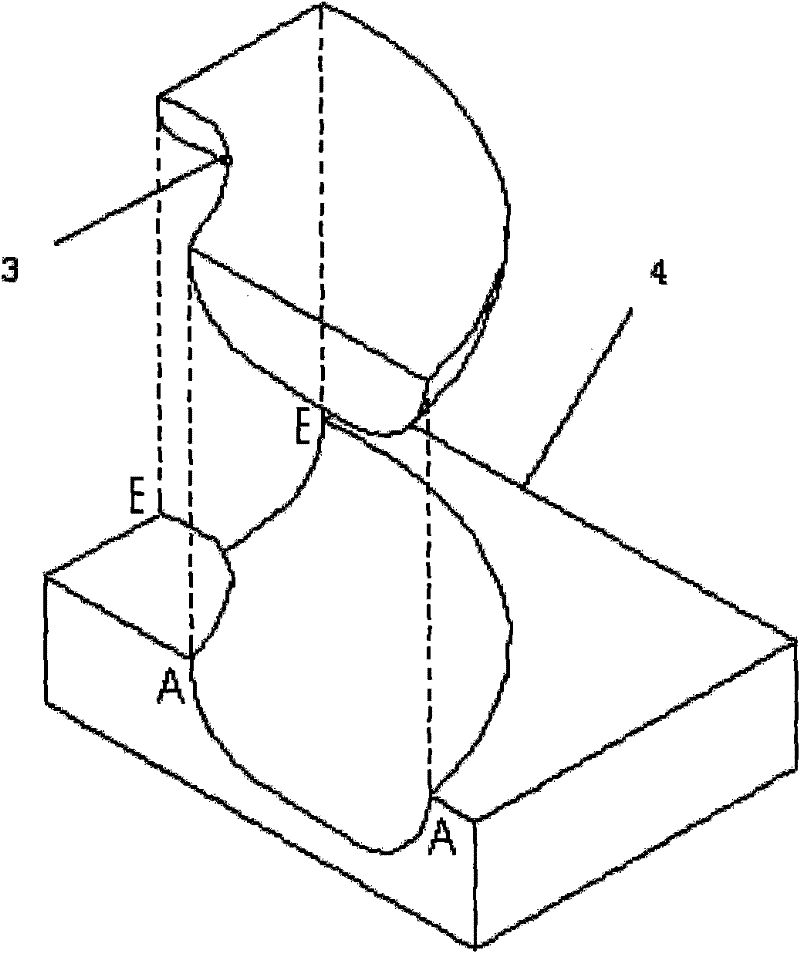

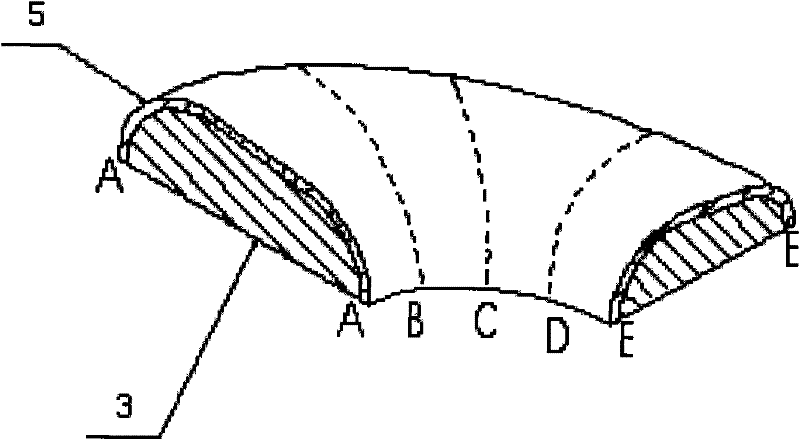

[0013] Bile removal is to make complex wooden molds with simple wooden molds. Figure 4 Parts shown, step 1, see figure 1 According to the shape of the inner cavity of the part 6 to be cast, a set of concave templates 2 for each section of A~E is made, and the parts are positioned according to the size direction of the part drawing. The shape of each section is shoveled on the dry wood with the template 2, and the sections are smoothly connected to form a wood. Entity 1; Step 2, see figure 2 , use the wooden entity 1 to make a master mold in the plastic core box 4, and then make a plastic entity 3 on the master mold; the third step, see image 3 , on the plastic entity 3, nail the material with the same thickness as the part 6 to be cast, and connect it smoothly with plastic to form the outer mold pattern 5.

[0014] The mechanical parts pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com