Multi-axis glass cutting apparatus

A glass cutting and equipment technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of uneven quality of pellets, large weight deviation of glass blocks, increased loss of raw materials, etc., to achieve good quality, operation and use. Simple, loss-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

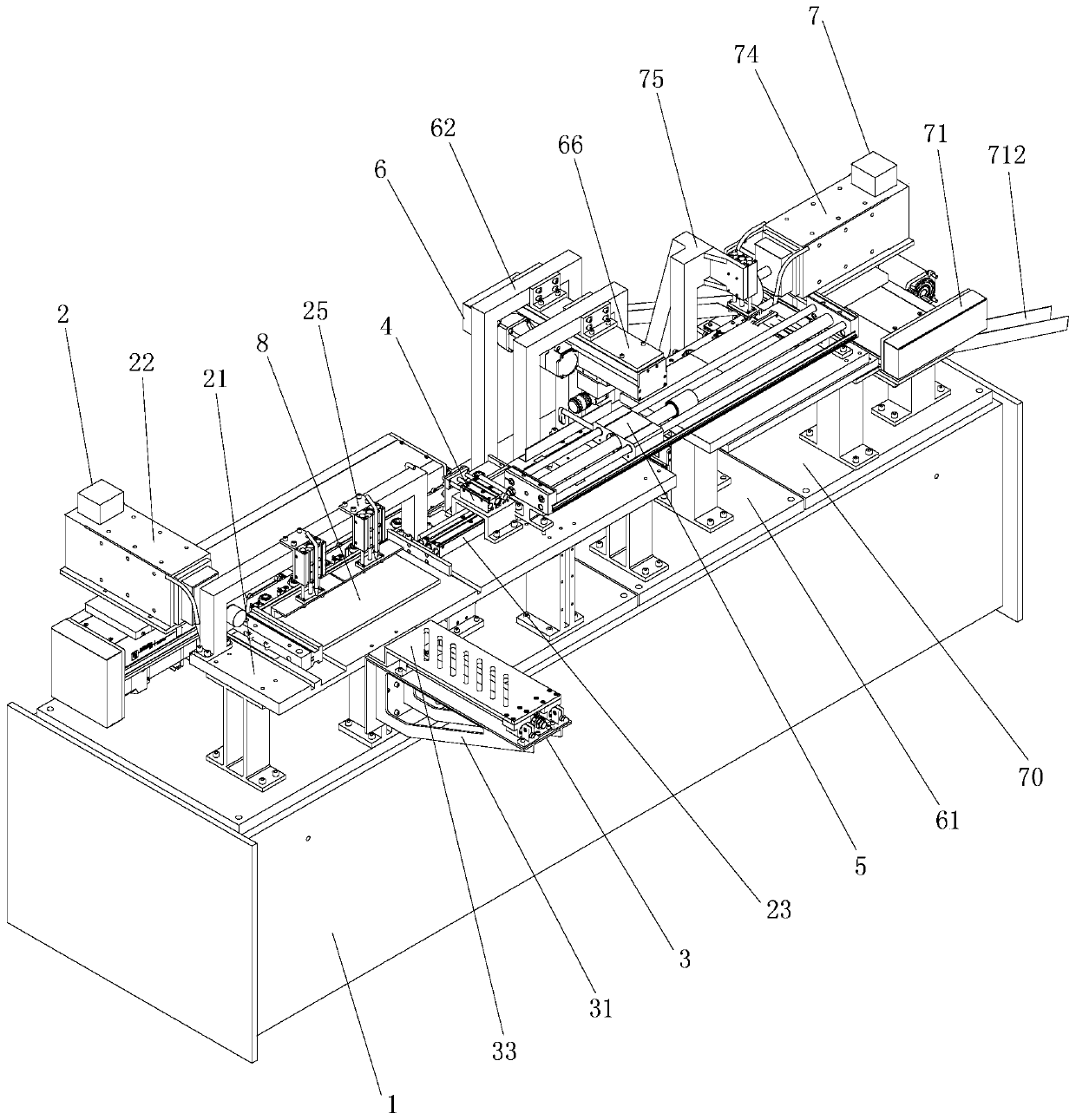

[0035] Such as Figures 1 to 9 As shown, the multi-axis glass cutting equipment of the present invention includes a base 1, a strip opening mechanism 2, a feeding mechanism 3, a strip opening setting mechanism 4, a glass strip pushing mechanism 5, a detection mechanism 6, a cutting mechanism 7, a PLC control system and Air source system connected with PLC control system.

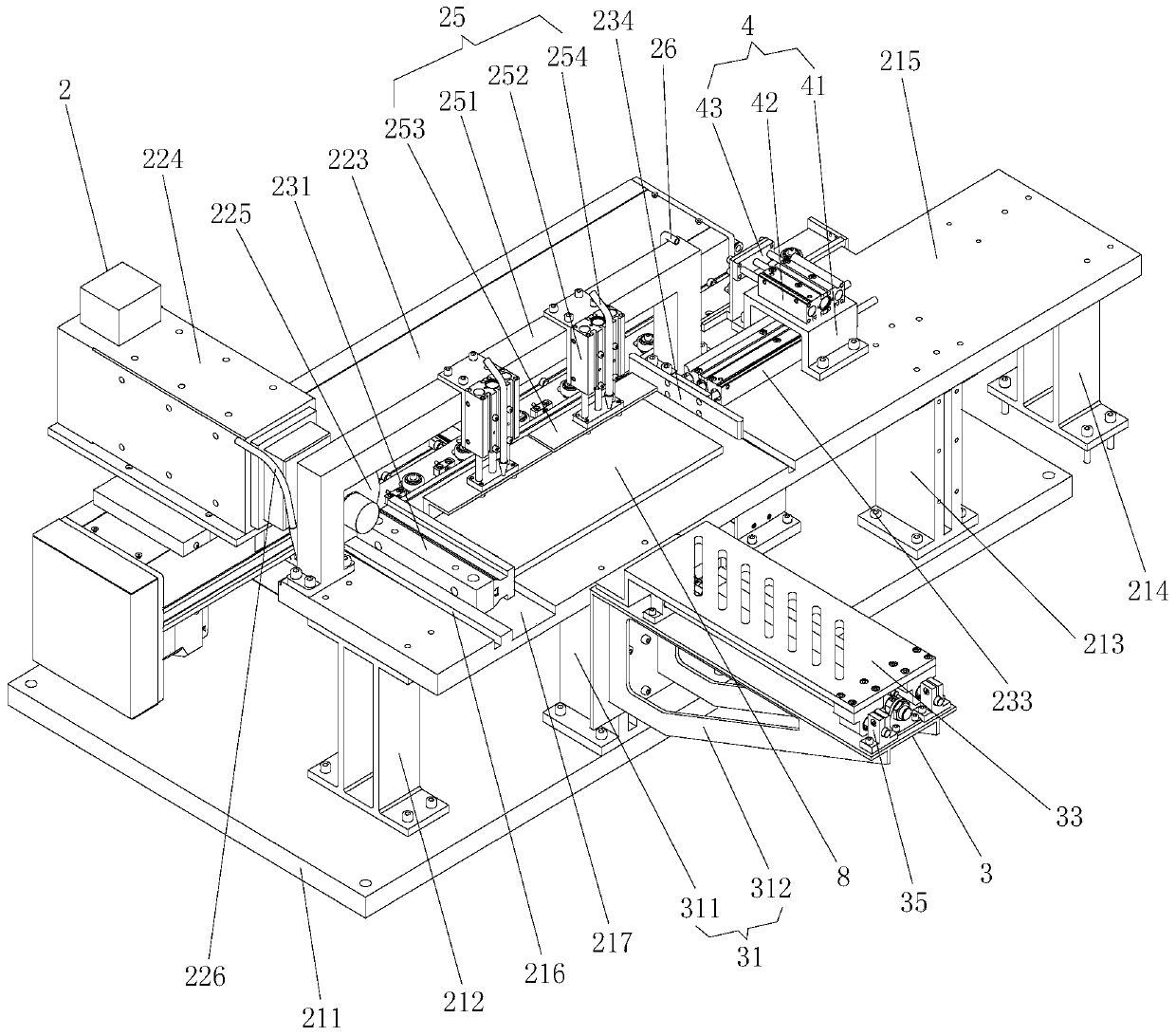

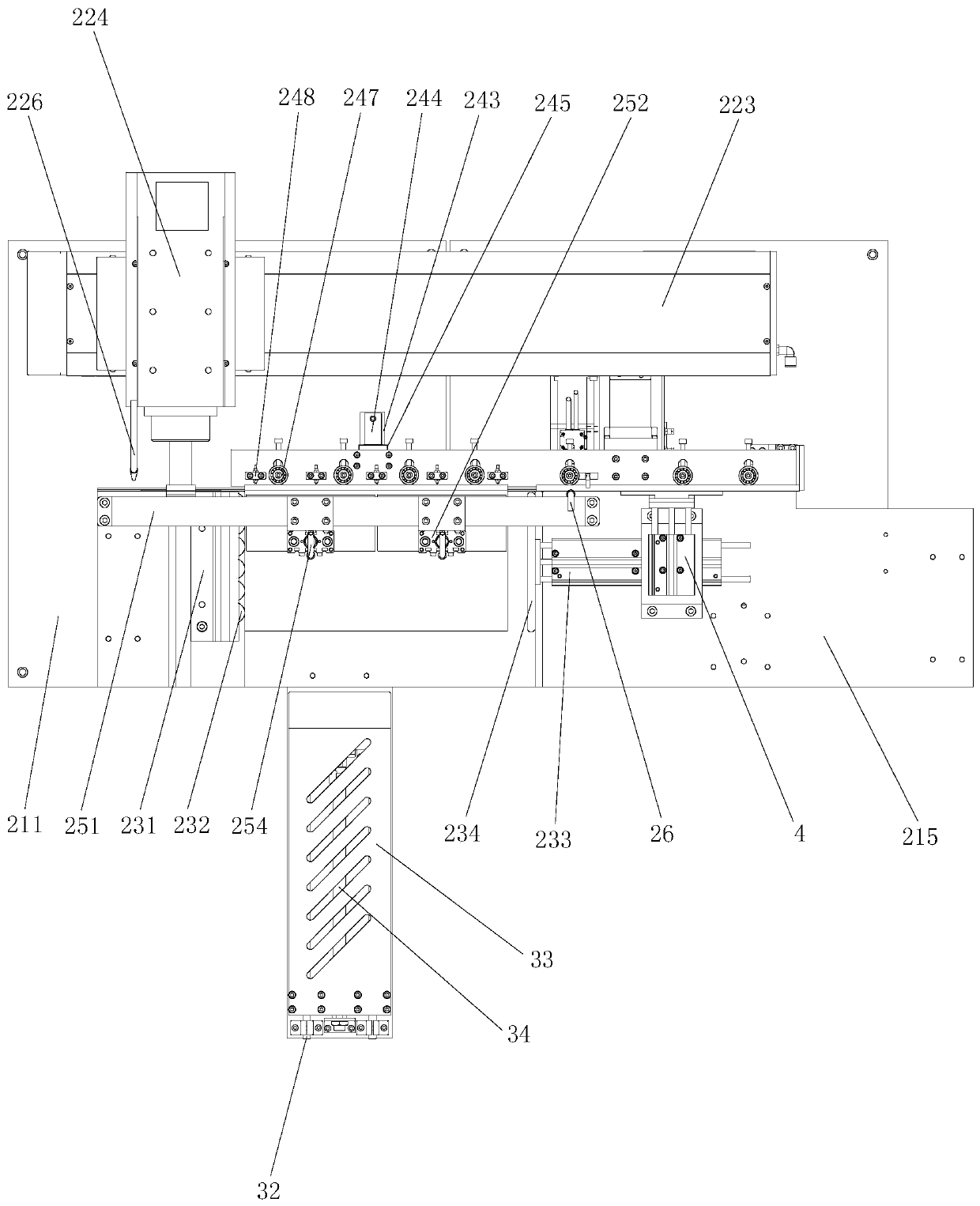

[0036] The base 1 is placed on the ground, such as Figure 2-4 As shown, the opening mechanism 2 is installed on the top surface of the base 1 and includes an opening table 21, an opening cutting device 22, an X-direction positioning device 23, a Y-direction positioning device 24, a Z-direction pressing device 25, and a blowing device. 26 and tail positioning device 27.

[0037] The strip workbench 21 is installed on the top surface of the base 1 and includes a strip lower base plate 211, an X-direction head support frame 212, an X-direction middle support frame 213, an X-direction tail support frame 214 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com