Feeding system for magnet rotor pressing process

A feeding system and rotor technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of unstable product size, difficulty in controlling the amount of feeding, and unequal feeding, achieving small weight deviations, The effect of uniform weight and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

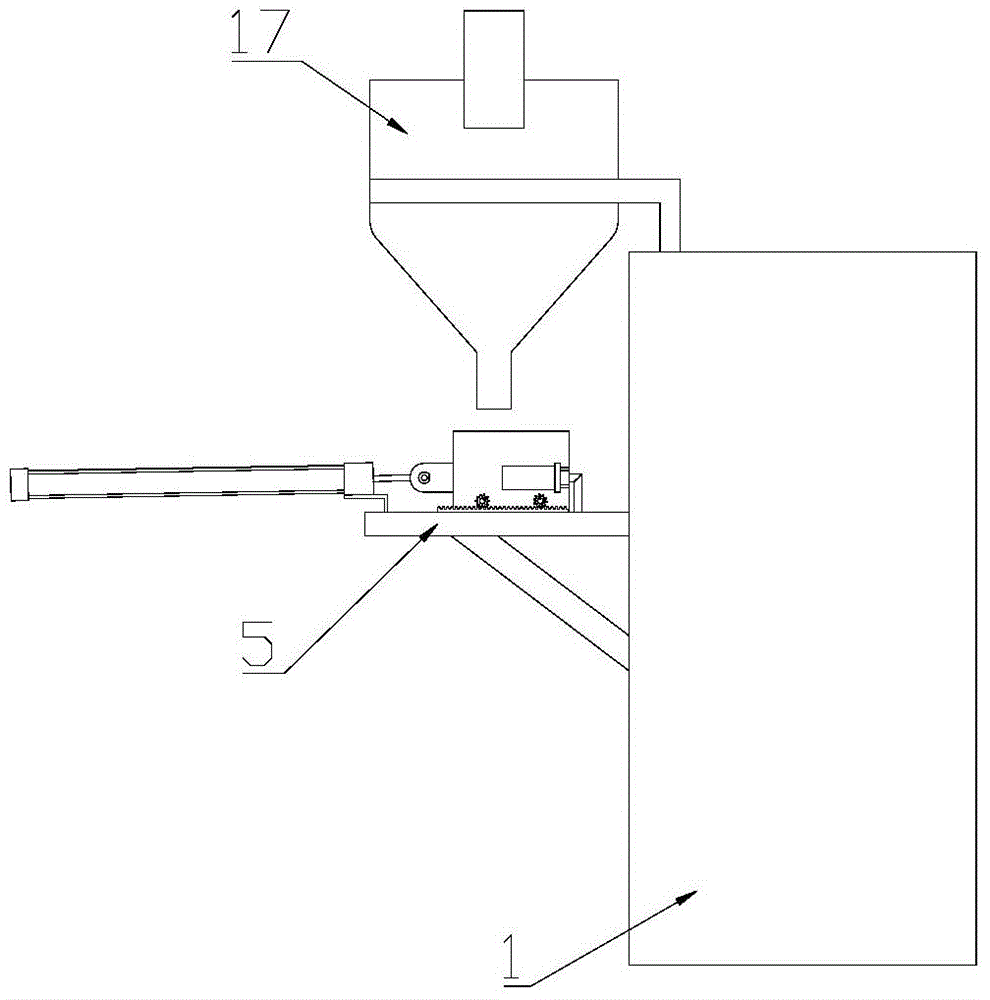

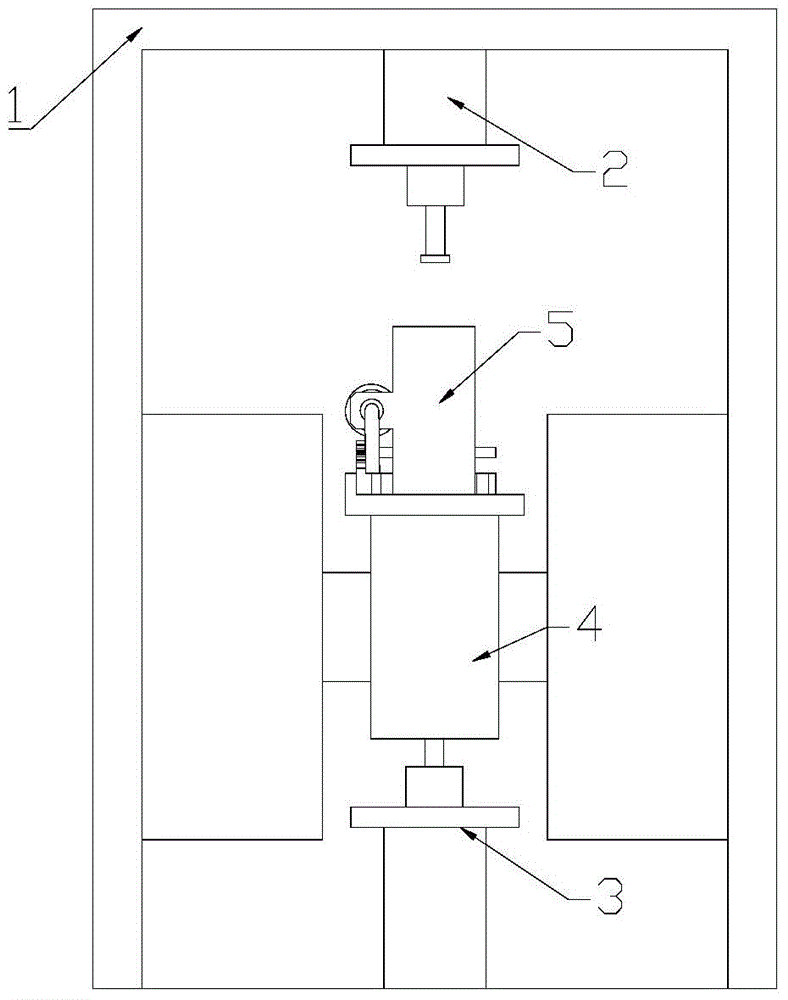

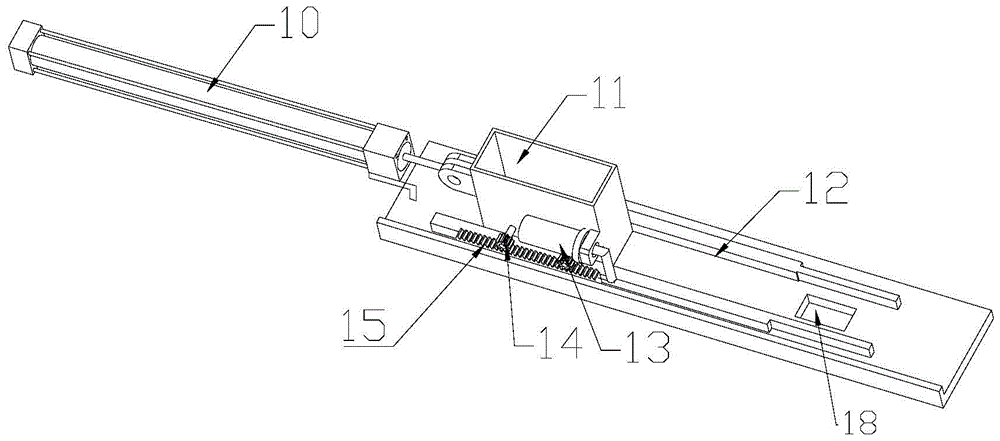

[0020] Such as figure 1 Shown is the feeding system of the magnet rotor pressing process of the present invention, as the most basic structure, it includes a storage funnel 17 and a feeding device 5 . Such as Figure 2~3 As shown, the feeding device 5 includes a material box 11, a bottom plate 12, a slide rail fixed on the bottom plate, and a forward drive device for pushing the material box 11 to move along the slide rail. Such as Figure 5 As shown, the material box 11 is a rectangular box with upper and lower openings, and one end of the material box is provided with a hanging ear for connecting the driving device. When magazine 11 is in such as figure 2 and image 3 When the first position of the slide rail is shown, it is facing directly below the outlet of the storage hopper 17 and can receive materials from the storage hopper. When the material box 11 is delivered to the second position of the other end of the slide rail, facing the material inlet of the mould, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com