Method for producing olefin by catalytically cracking

A catalytic cracking, olefin technology, applied in catalytic cracking, bulk chemical production, chemical instruments and methods, etc., can solve the problem of low catalyst activity, and achieve the effect of high activity, high sphericity, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 500 grams of kaolin and 2 grams of safflower powder, mix evenly, add 2000 grams of distilled water, shear at high speed with a high-speed shear for 30 minutes, then add 100 grams of aluminum sol containing 20% by weight of aluminum oxide and 40% by weight of silicon oxide % of aluminum sol 400 grams, continue high-speed shearing for 30 minutes, then add 1 gram of triammonium citrate, 4 grams of calcium carbonate, continue high-speed shearing for 30 minutes, measure the particle size of this suspension with a laser particle size analyzer, the average The particle size is 2 microns. Spray molding with a spray dryer, the spray molding conditions are: inlet temperature 240°C, outlet temperature 120°C, centrifugal speed 10000 rpm, cyclone pressure difference at the outlet is 0.7KPa, feed rate is 1 kg / hour, and the formed micro Ball Catalyst Precursor I. The catalyst precursor I was calcined by temperature programming at 400° C. for 3 hours, and then at 650° C. for 3...

Embodiment 2~10

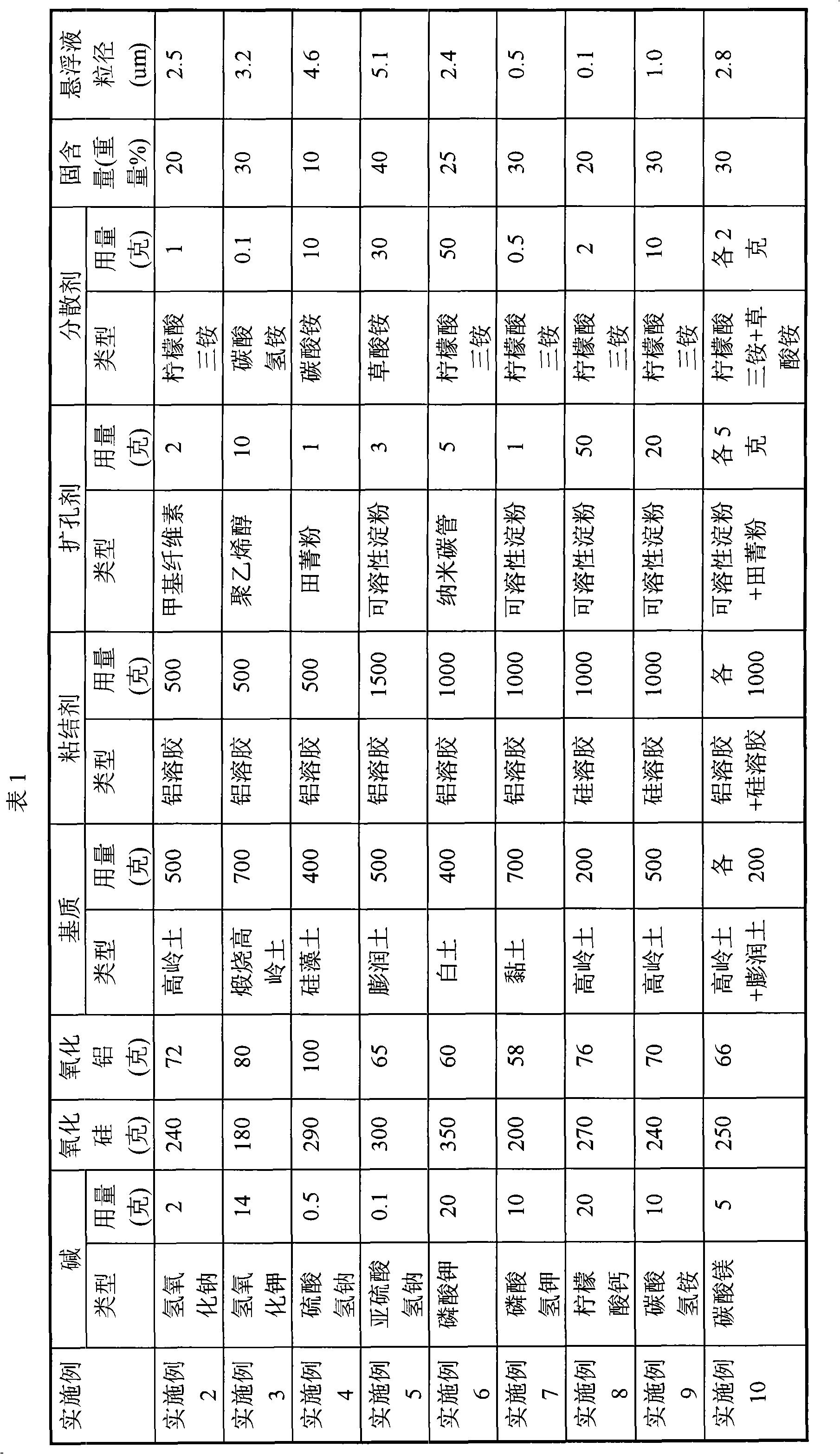

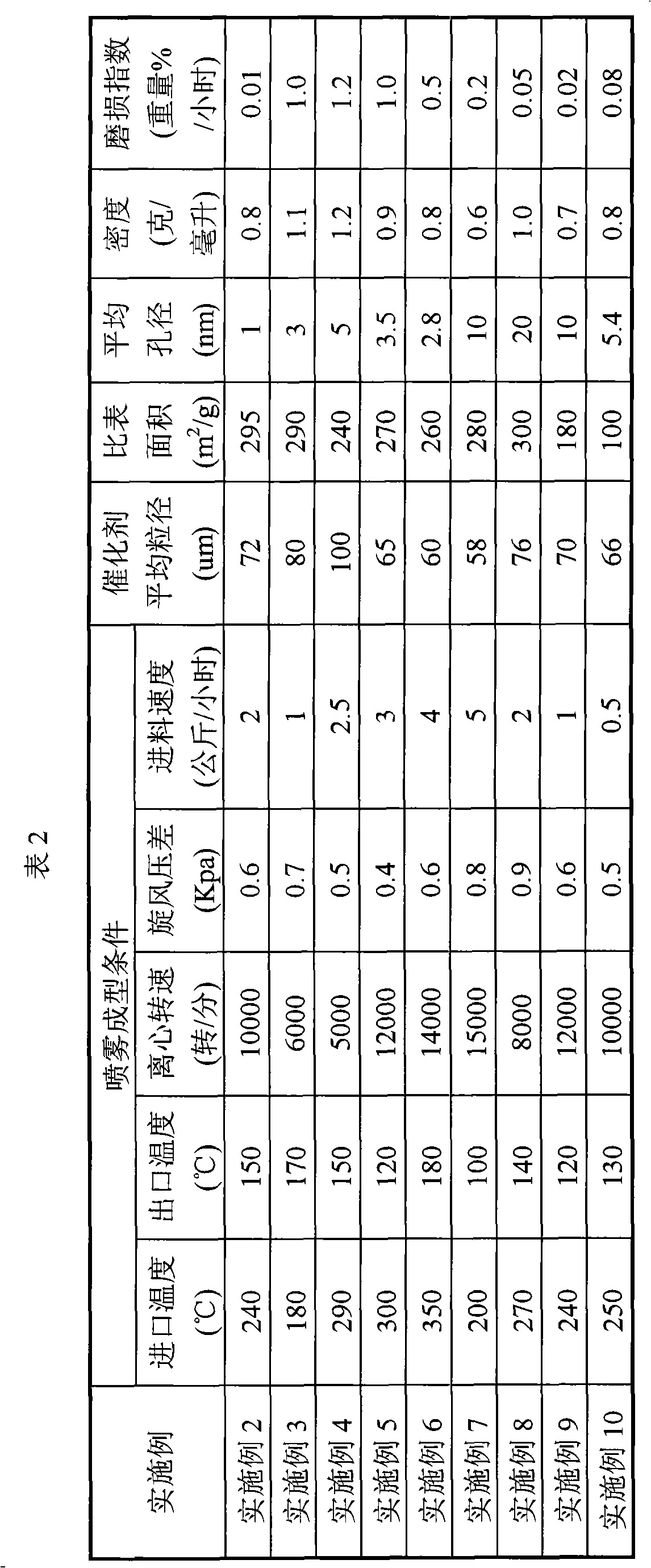

[0036] According to the method of Example 1, using the ingredients and preparation conditions in Table 1 and Table 3, wherein the silica sol contains 40% by weight of silicon dioxide, the performance of the prepared fluidized bed catalyst is shown in Table 2.

[0037]

[0038]

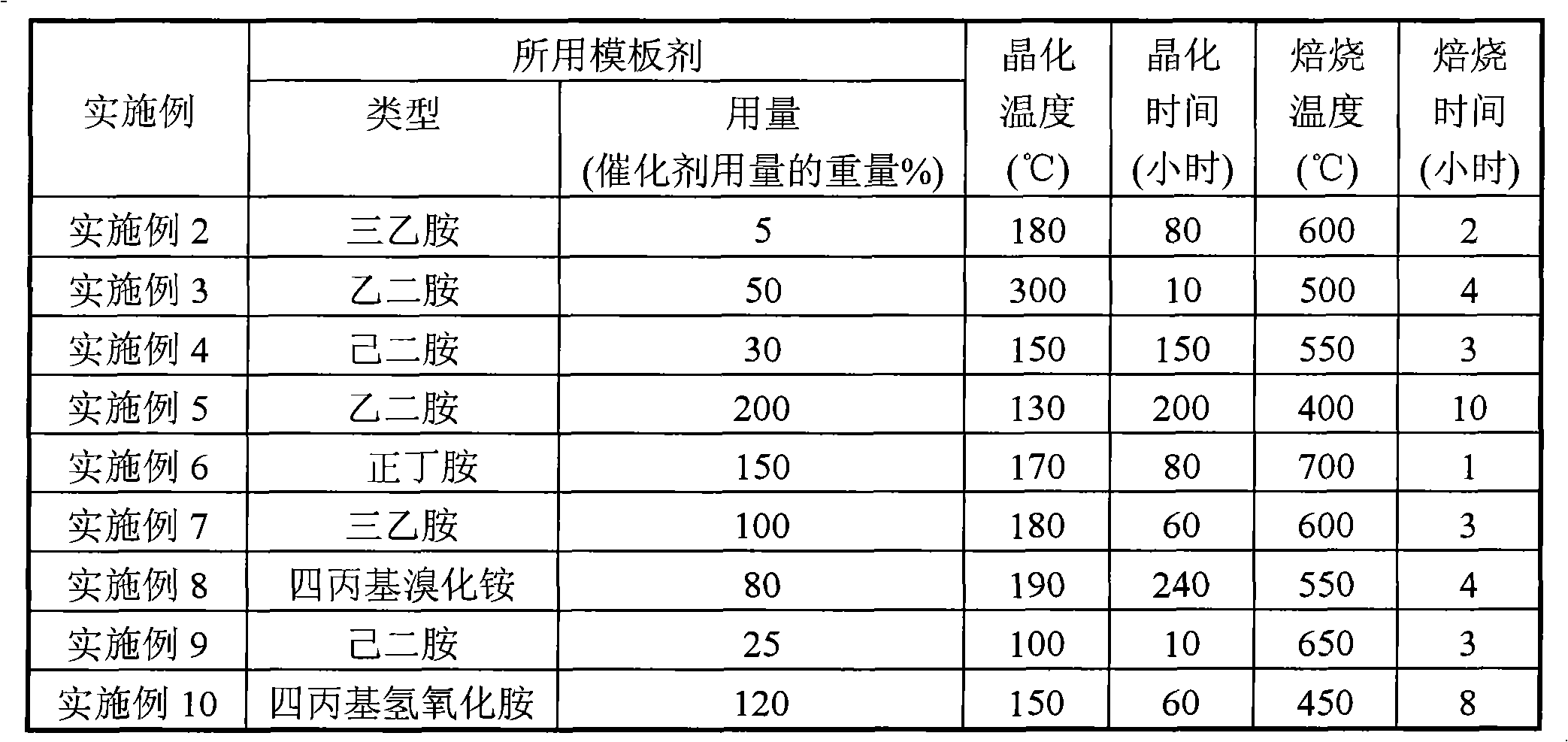

[0039] table 3

[0040]

Embodiment 11

[0042] Get the method for 200 grams of embodiment 1 to make fluidized bed ZSM-5 / mordenite intergrowth molecular sieve catalyst, put into internal diameter and be the fluidized bed reactor of 50 millimeters, adopt the component that Shanghai Gaoqiao petrochemical company produces is C 4 ~C 10 The light oil is used as the raw material (see Table 4 for the physical properties of the raw material), and the activity of the catalyst is evaluated. The reaction temperature range is 680 ° C, the reaction pressure is 0.02 MPa, and the weight space velocity is 1 hour -1 , Water / feedstock oil weight ratio is 1: 1 under evaluation, product distribution is shown in Table 5, obtains ethylene weight yield and is 28%, and propylene weight yield is 22%, and diene weight total yield is 50%.

[0043] Table 4 Light Oil Raw Material Indicators

[0044] project data Density(20℃)kg / m 3 704.6 Distillation Range Initial Distillation Range °C 40 Final boiling range °C 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com