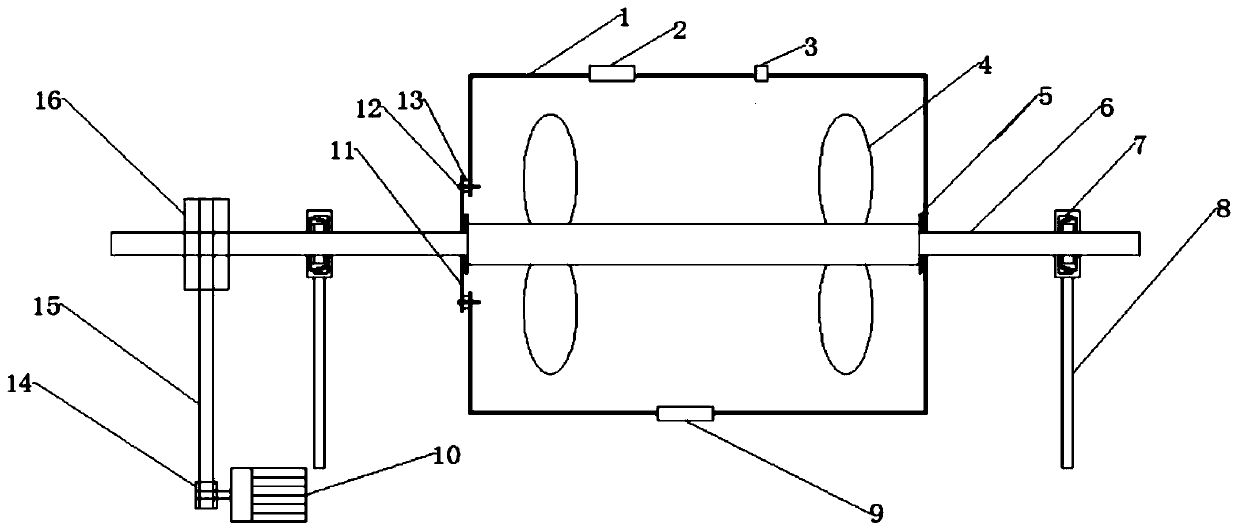

Cement stirring machine

A technology of cement mixer and mixing barrel, which is applied to cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve the problems of long mixing cycle, low production efficiency, low mixing uniformity, etc., and achieves convenient manufacturing, installation and maintenance. Simple structure and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

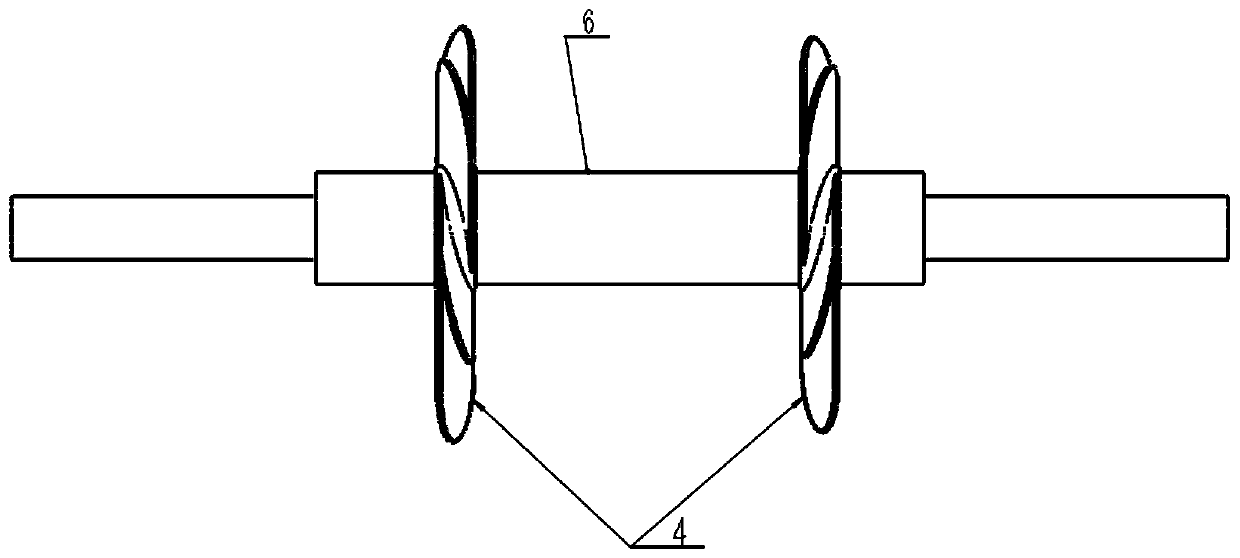

[0019] In the embodiment of the present invention, such as figure 1 , figure 2 As shown, the cement mixer includes a cylindrical and hollow mixing tank 1, which is a working space for mixing and stirring the mud-water mixture; the side of the mixing tank body is provided with a feed hole 2, a water inlet 3, and a discharge port 9. To inject lime, water and flow out the stirred cement; place the sealing ring 5 where the stirring shaft 6 contacts the end face of the mixing drum 1 and the end face cover to ensure the sealing; one of the end faces of the barrel body is equipped with a detachable end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com