Method for producing propylene by oxygen-containing compound conversion

A compound and propylene technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low catalyst activity and achieve high activity, high sphericity, and difficult to agglomerate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take by weighing 500 grams of kaolin and 2 grams of fennel powder, after mixing evenly, add 2000 grams of distilled water, shear at a high speed for 30 minutes with a high-speed shearing machine, then add 500 grams of silica sol containing 40% by weight of silicon oxide, and continue high-speed shearing for 30 minutes Minutes, then add 1 gram of triammonium citrate, 2 grams of sodium carbonate, after continuing high-speed shearing for 30 minutes, measure the particle size of this suspension with a laser particle size analyzer, and its average particle diameter is 2 microns. Spray molding with a spray dryer, the spray molding conditions are: inlet temperature 240°C, outlet temperature 120°C, centrifugal speed 10000 rpm, cyclone pressure difference at the outlet is 0.7KPa, feed rate is 1 kg / hour, and the formed micro Ball Catalyst Precursor I. The catalyst precursor I was calcined by temperature programming at 400° C. for 3 hours, and then at 650° C. for 3 hours to obtain...

Embodiment 2~10

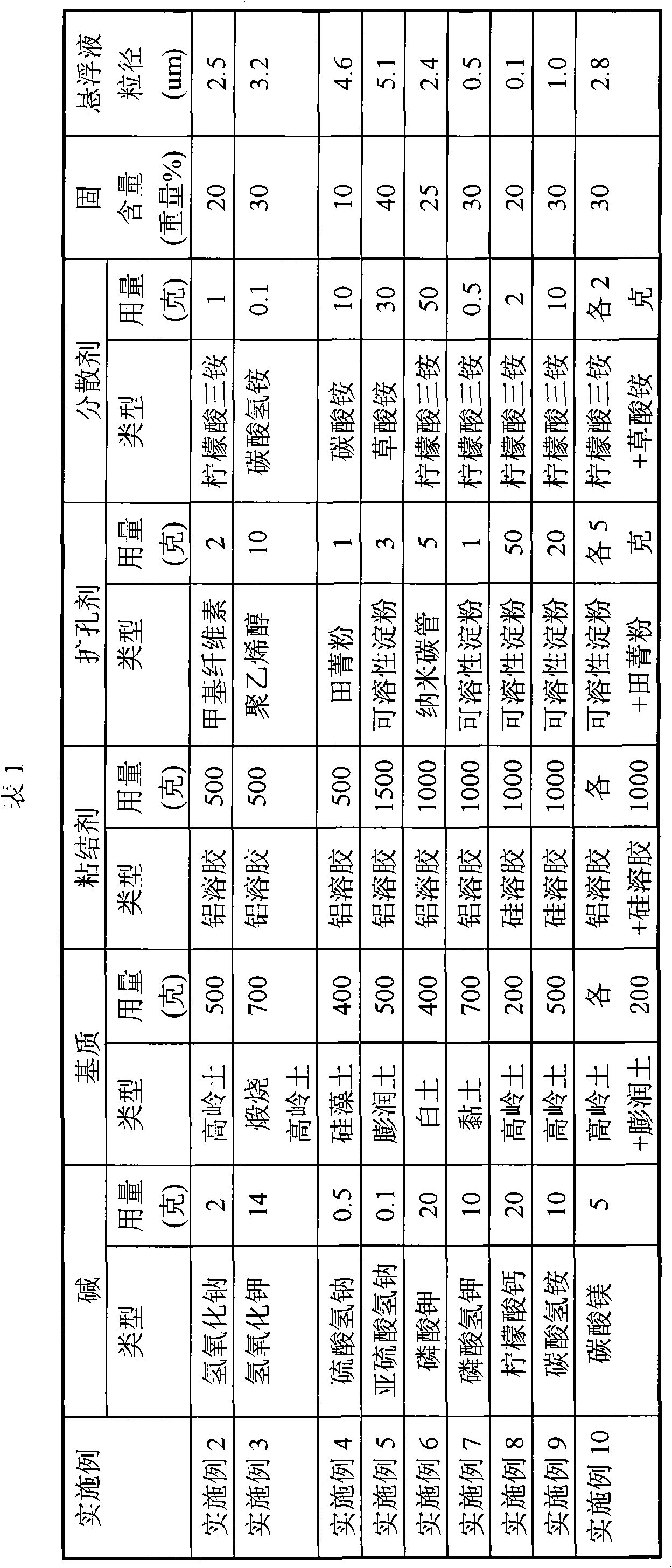

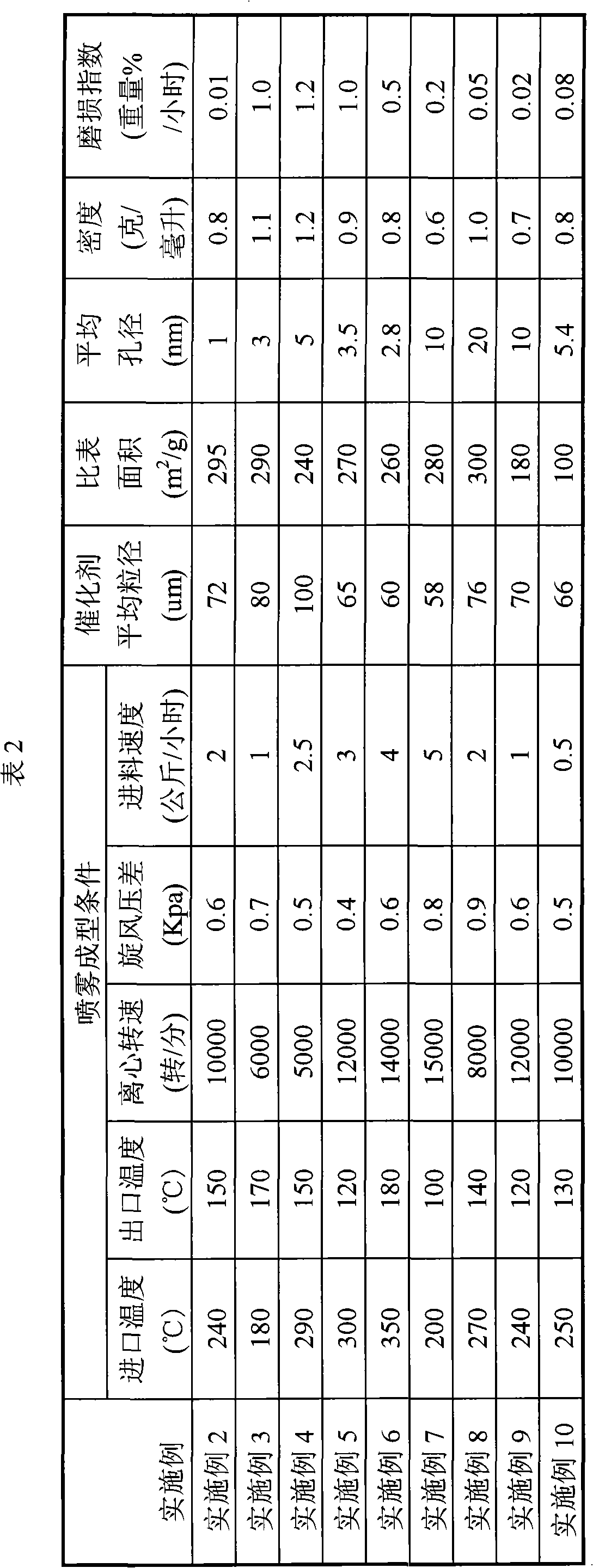

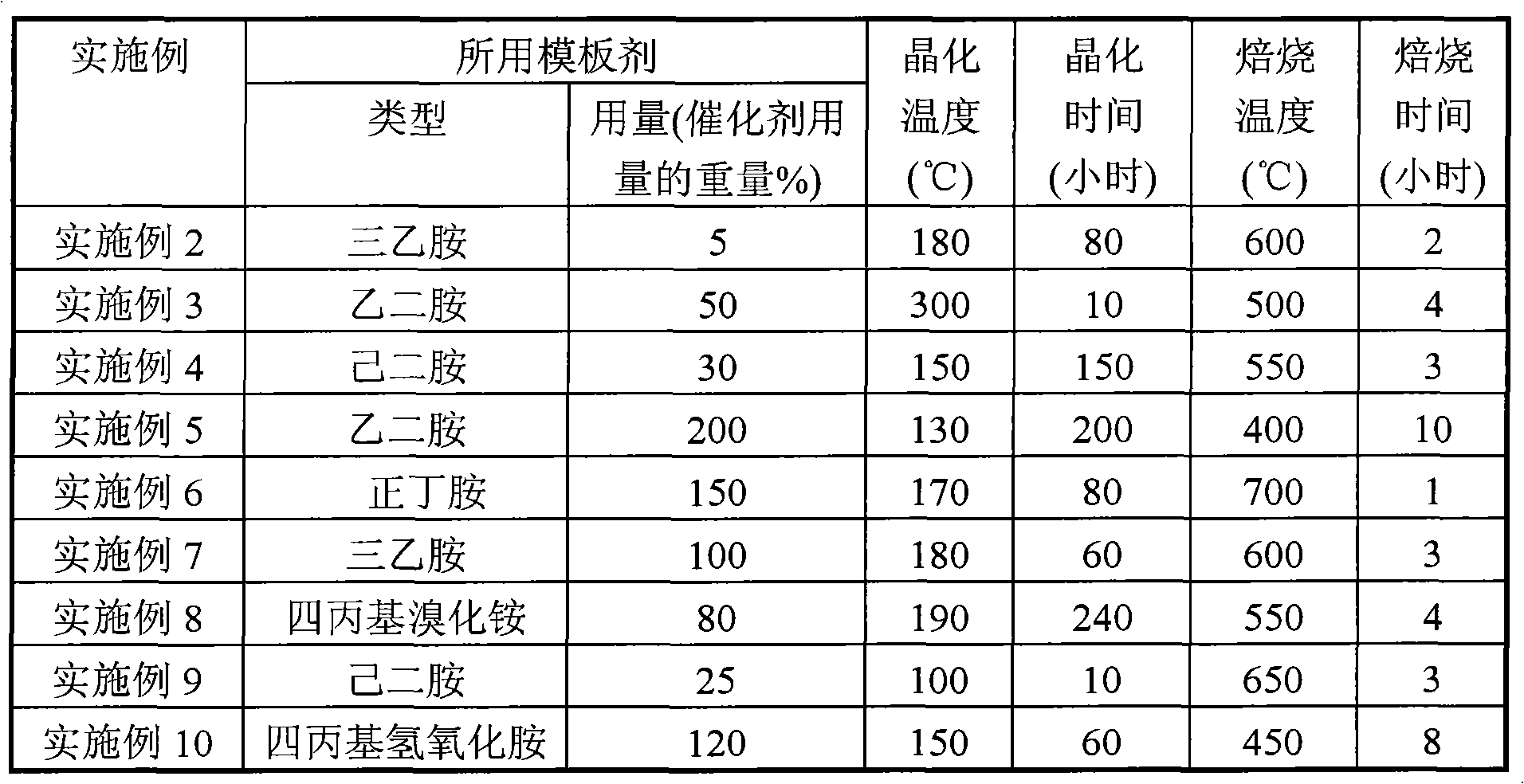

[0026] According to the method of Example 1, using the ingredients and preparation conditions in Table 1 and Table 3, wherein the silica sol contains 40% by weight of silicon dioxide, the performance of the prepared fluidized bed catalyst is shown in Table 2.

[0027]

[0028]

[0029] table 3

[0030]

Embodiment 11

[0032] Get 200 grams of the method of embodiment 1 to make the fluidized bed ZSM-5 catalyst, put into the fluidized bed reactor that internal diameter is 50 millimeters, take methanol as raw material, at 480 ℃, weight space velocity 1h -1 , Water / methanol weight ratio 1: 1, pressure under the condition of 0.02MPa evaluation, the weight yield of ethylene reaches 25%, the weight yield of propylene reaches 50%, the product distribution is shown in Table 4, and the total yield of diene weight is 75%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com