Method for preparing lithium ion battery negative pole piece

A lithium-ion battery and negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of time-consuming, increase equipment investment and energy consumption, affect production efficiency, etc., achieve a wide range of applications and save equipment investment. and energy consumption, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a negative electrode sheet of a lithium ion battery. The preparation method comprises the following steps:

[0035] S1, dry mixing the negative electrode active material and the conductive agent to obtain a dry blend;

[0036] S2, adding negative electrode additives, thickeners and a first solvent to the dry mixture to obtain a first mixture;

[0037] S3, adding a binder and a second solvent to the first mixture to obtain a second mixture;

[0038] S4, adding a third solvent to the second mixture to obtain a prefabricated slurry, and coating the prefabricated slurry to obtain a lithium ion battery negative electrode sheet.

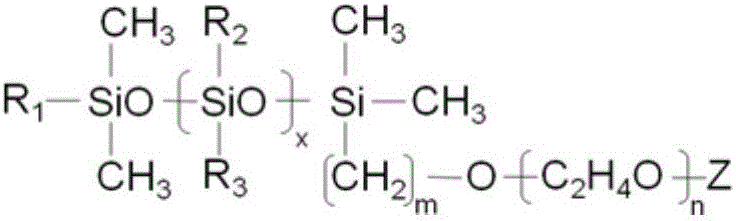

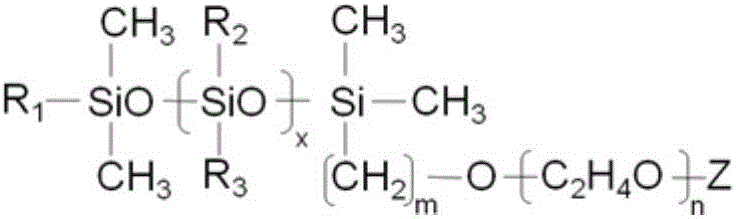

[0039] Wherein, the negative electrode additive is a polyether-modified silicone oil, and the general chemical formula of the polyether-modified silicone oil is:

[0040]

[0041] Wherein, x is an integer of 2 to 8, m is an integer of 5 to 8, n is an integer of 5 to 8, R 1 , R 2 , R 3 C for hyd...

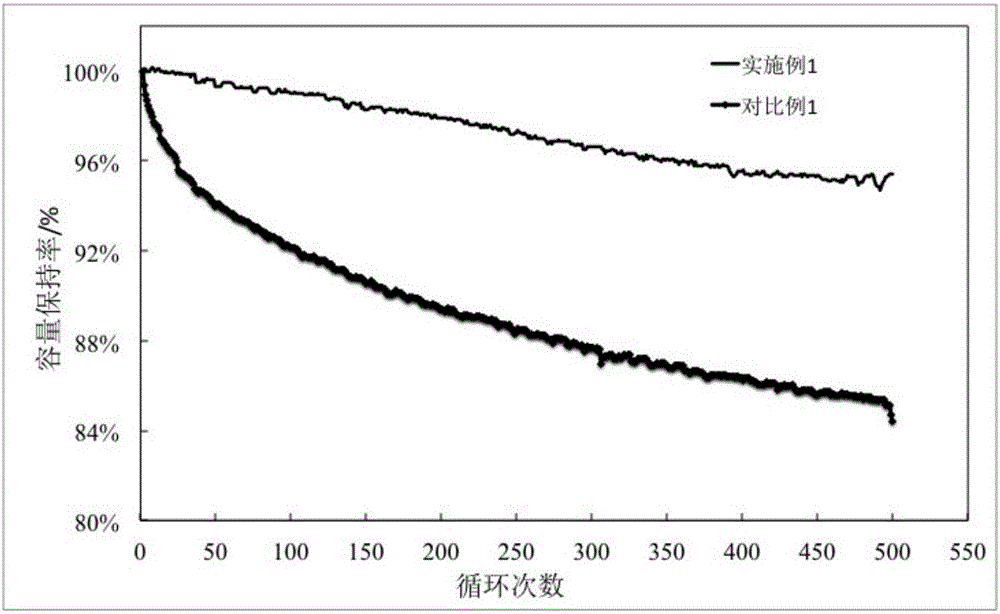

Embodiment 1

[0050] 93g of negative electrode active material and 1.5g of conductive agent were dry mixed to obtain a dry blend, wherein the negative electrode active material was artificial graphite, and the conductive agent was Super P.

[0051] Add 2g of negative electrode additive, 2g of CMC and 45g of water to the dry mixture to obtain the first mixture, wherein the negative electrode additive is silicone oil co-modified by allyl group containing epoxy group and polyether.

[0052] 1.5 g of binder and 35 g of water were added to the first mixture to obtain a second mixture in which the binder was .

[0053] 40 g of water was added to the second mixture to obtain a prefabricated slurry, and the prefabricated slurry was coated to obtain a lithium ion battery negative electrode sheet.

Embodiment 2

[0055] 95.5 g of the negative electrode active material and 0.5 g of the conductive agent were dry mixed to obtain a dry mixture, wherein the negative electrode active material was graphite, and the conductive agent was carbon nanotubes.

[0056] 2 g of negative electrode additive and 35 g of NMP were added to the dry mixture to obtain a first mixture, wherein the negative electrode additive was lithiated polyether-modified silicone oil.

[0057] 2 g of binder and 35 g of NMP were added to the first mixture to obtain a second mixture in which the binder was PVDF.

[0058] 50 g of NMP was added to the second mixture to obtain a prefabricated slurry, and the prefabricated slurry was coated to obtain a lithium ion battery negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com