Cooking auxiliary agent for papermaking and pulping

A cooking aid and pulping technology, applied in the field of papermaking, can solve the problems of long lignin decomposition and dissolution time, affecting the quality and yield of pulp, and poor solubility of cooking aids, so as to save steam consumption and shorten cooking The effect of time and slurry drift loss is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The described cooking aid for papermaking and pulping consists of the following components in percentage by weight:

[0033] Fatty alcohol polyoxyethylene ether 12%

[0034] Sodium dodecylbenzenesulfonate 20%

[0035] Sodium Alkyl Sulfonamide Acetate 8%

[0036] Alkylphenol ethoxylates 8%

[0037] Sodium nonylphenol ethoxylate sulfonate 5%

[0038] Dimethylsulfonic acid 3%

[0039] Sodium Carboxymethyl Cellulose 5%

[0040] Oleamide 1.2%

[0041] Sodium pyrophosphate 0.5%

[0042] Deionized water balance

Embodiment 2

[0044] The described cooking aid for papermaking and pulping consists of the following components in percentage by weight:

[0045] Fatty alcohol polyoxyethylene ether 8%

[0046] Sodium dodecylbenzenesulfonate 10%

[0047] Sodium Alkyl Sulfonamide Acetate 3%

[0048] Alkylphenol ethoxylates 3%

[0049] Sodium Nonylphenol Ethoxylate Sulfonate 2%

[0050] Dimethylsulfonic acid 1%

[0051] Sodium Carboxymethyl Cellulose 2%

[0052] Oleamide 0.5%

[0053] Sodium pyrophosphate 0.1%

[0054] Deionized water balance

Embodiment 3

[0056] The described cooking aid for papermaking and pulping consists of the following components in percentage by weight:

[0057] Fatty alcohol polyoxyethylene ether 10%

[0058] Sodium dodecylbenzenesulfonate 15%

[0059] Sodium Alkyl Sulfonamide Acetate 5%

[0060] Alkylphenol ethoxylates 5%

[0061] Sodium Nonylphenol Ethoxylate Sulfonate 3%

[0062] Dimethylsulfonic acid 2%

[0063] Sodium Carboxymethyl Cellulose 3%

[0064] Oleamide 1%

[0065] Sodium pyrophosphate 0.3%

[0066] Deionized water balance

[0067] The present invention will be further described below in conjunction with specific experiments.

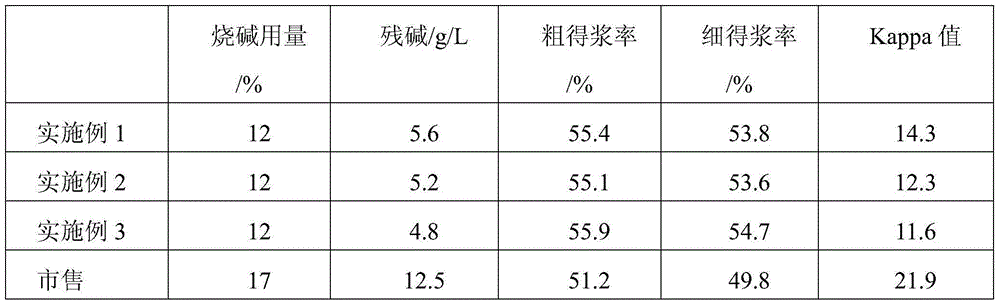

[0068] Table 1 shows the effect of using the cooking aids of Examples 1, 2, and 3 of the present invention and commercially available cooking aids in alkaline pulping under other conditions of the same process.

[0069] Table 1

[0070]

[0071] It can be seen from the above experimental data that the cooking aid for papermaking and pulping of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com