High-strength ultrathin heat-insulation paper, preparation method and application thereof

A heat-insulating paper, high-strength technology, used in papermaking, textiles and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc. The effect of isolating heat convection, improving tensile strength, and maintaining high vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

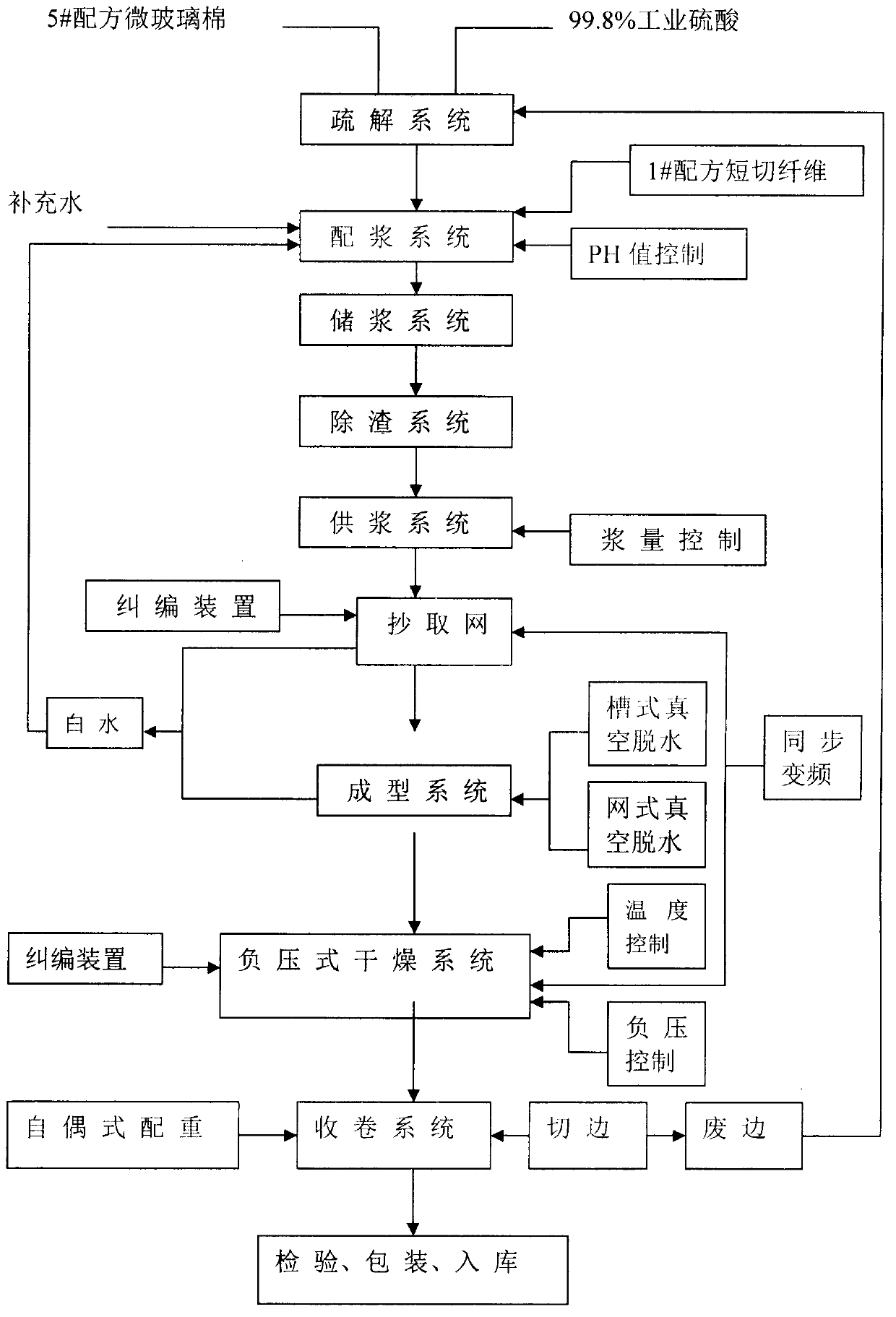

Image

Examples

Embodiment 1

[0024] Embodiment 1: (1) put 19.6 kilograms of micro-glass wool with a diameter of 0.1 to 1.0 mm and a degree of knocking of 49 degrees into the decontamination system, and decompose it in a hydraulic pulping mode, dilute it to 1.2% with water, and add a concentration of 98% to industrial Sulfuric acid, adjusted to a pH value of 2.5; (2) 0.4 kg of 4-5um in diameter and 4-6mm in length 1# formula alkali-free chopped fiber was added, and added water (natural water) or reused white water was further diluted to 0.8 % adjust the pH value to 2.5 (detected by the acidity meter) and stir through the vertical flap turbine agitator; (3) after stirring evenly, use the pump to enter the slurry storage system, and continue to stir by the vertical flap turbine agitator, In order to maintain a relatively stable slurry; (4) The stable slurry is sent to the slurry supply system after being treated by a cone-type slag remover, and then diluted to 0.01% with white water again, and then copied onl...

Embodiment 2

[0026] Embodiment 2: (1) 5.88kg diameter 0.1~1.0um, the micro-glass wool that knocks degree is 45 degrees is put into deflagging system, and deflagging machine adopts hydropulper mode to decompose, add the industrial sulfuric acid that concentration is 99.8%, dilute with water to 1.2%, adjust to PH value of 2.5; (2) drop into 0.4 kilograms of diameter and be 4~5um, the length is the 1# formula alkali-free chopped fiber of 4~6mm and add supplementary water (natural water) or reuse white water to further dilute To 0.8%, adjust the pH value to 2.5, and stir through the vertical folded-leaf turbine agitator; (3) after stirring evenly, use the pump to enter the slurry storage system, and continue to stir by the vertical folded-leaf turbine stirrer to maintain relative Stable slurry; (4) Stable slurry is sent to the slurry supply system after being treated by a cone-type slag remover, and then diluted to 0.02% with white water again, and then copied online; (6) enter the negative pr...

Embodiment 3

[0028] Embodiment 3: A high-strength ultra-thin thermal insulation paper, which is made by mixing micro-glass wool and alkali-free chopped glass fibers. Among them, the micro glass wool is made by the flame method of the all-electric melting furnace, and its diameter is 0.001-0.01mm, and the degree of percussion is 39-450SR; It is made by chopping parallel drums, its diameter is 0.004-0.0055mm, and its length is 4-6mm; All the other preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com