Automatic grease application device and method for bolt

A bolt and automatic technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of low production efficiency, arm weakness, uneven coating of lubricating paste, etc., to ensure the coating effect and reduce labor intensity , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

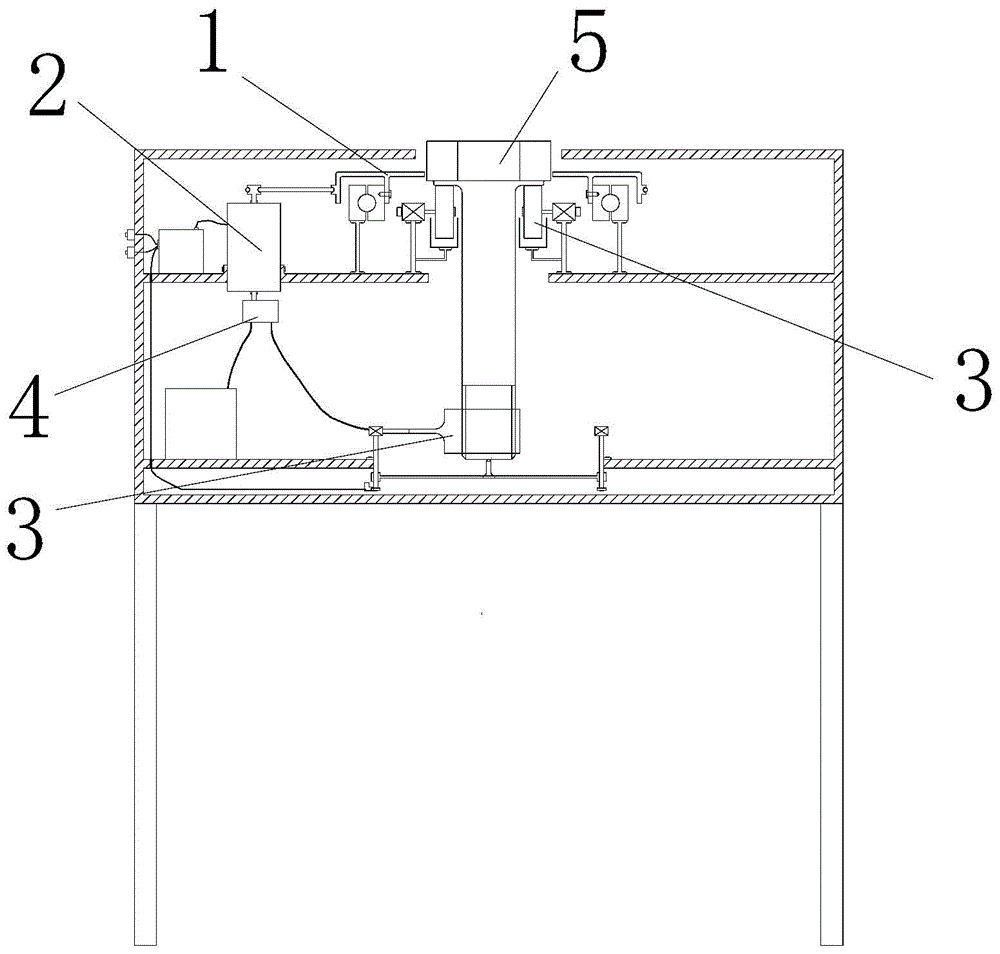

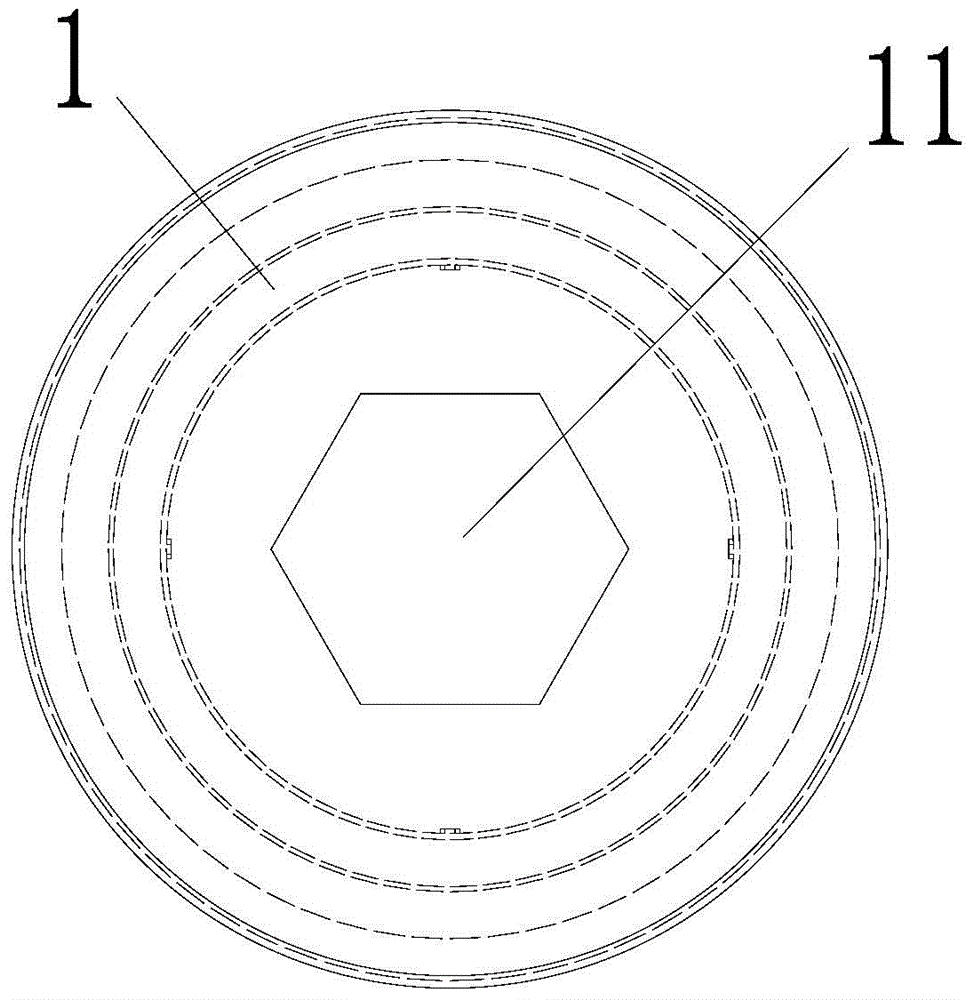

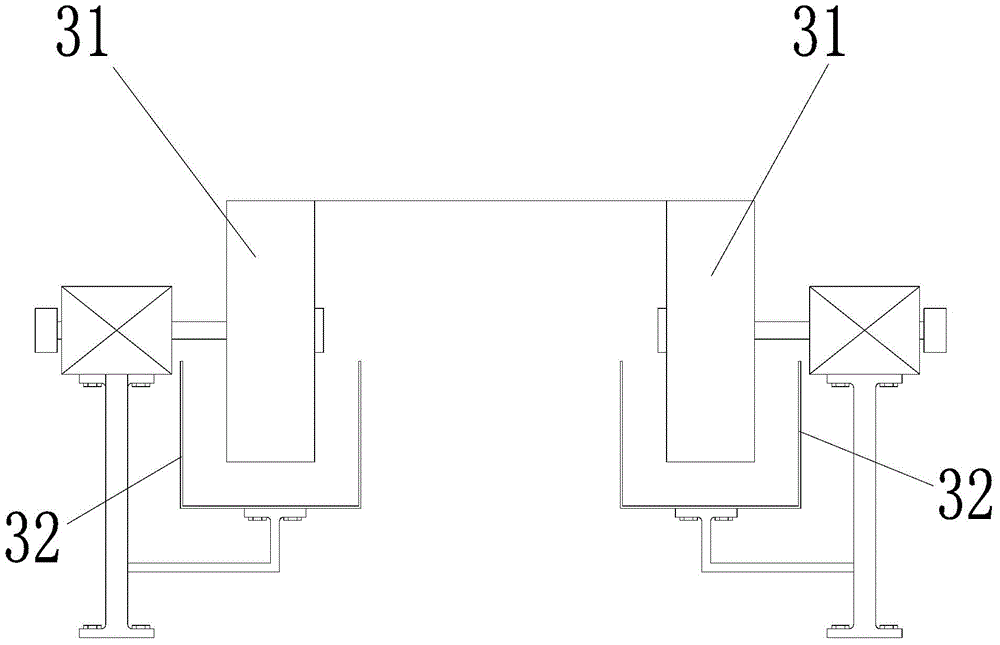

[0051] Such as figure 1 , image 3 and Figure 4 As shown, a bolt automatic paste device includes a drive plate 1, a power mechanism 2 and a coating mechanism 3, the power mechanism 2 and the drive plate 1 are connected by transmission, the bolt 5 to be coated is installed on the drive plate 1, and the power mechanism 2 The driving disk 1 drives the bolt 5 to be coated to rotate around its own axis. The coating mechanism 3 includes a coating wheel 31 and a lubricating paste storage tank 32. The coating wheel 31 is arranged in the lubricating paste storage tank 32, and the coating wheel 31 touches the Connect to the surface to be coated of the bolt head of the bolt 5 to be coated, and roll relative to the surface to be coated of the bolt head, for applying the lubricating paste in the lubricating paste storage tank 32 to the surface to be coated of the bolt head.

[0052]Wherein, the transmission connection between the power mechanism 2 and the driving disk 1 can adopt conven...

Embodiment 2

[0066] Such as Figure 9 As shown, a bolt automatic paste method, using the bolt automatic paste device described in Embodiment 1, includes the steps: A, placing the bolt to be coated on the drive plate; B, driving the drive plate to drive the drive plate to be coated The bolt rotates, and the coating mechanism applies lubricating paste to the bolt to be coated. In this way, by rotating the bolt to be coated relative to the coating mechanism, the coating mechanism can automatically complete the coating operation of the bolt to be coated, which greatly saves manpower and improves work efficiency.

Embodiment approach

[0067] As a possible implementation mode, the use of a power mechanism including a drive motor and a battery automatic paste device for bolts; as Figure 9 As shown, after step A, it includes: step A1, relying on the gravity of the bolt to be coated to drive the position sensing bracket to move; A2, the position sensing bracket triggers the contact sensor to send a control signal; A3, the battery receives the contact sensor. After the control signal, it supplies power to the drive motor.

[0068] Preferably, step A3 includes: the storage battery receives the control signal sent by the contact sensor, and supplies power to the driving motor after a first predetermined time delay. The operator can preset the first predetermined time, such as 2 seconds. When the operator places the bolt to be coated, the battery will not immediately supply power to the drive motor after receiving the control signal from the contact sensor, but will be delayed for 2 seconds. Seconds later, power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com