Wire insulation coating device

An insulating coating and wire technology, which is used in devices for coating liquid on the surface, insulation/armored cable repair equipment, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments.

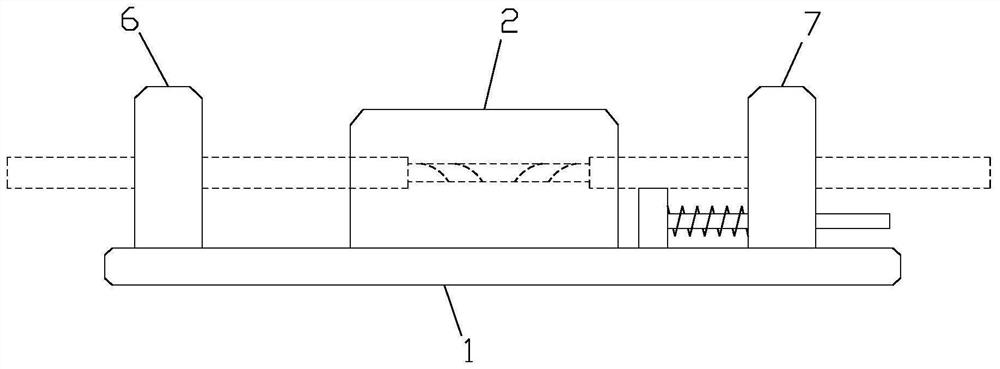

[0053] In order to realize the purpose of the above invention, such as Figure 1-11 As shown, the invention provides a wire insulation coating device, comprising:

[0054] base1;

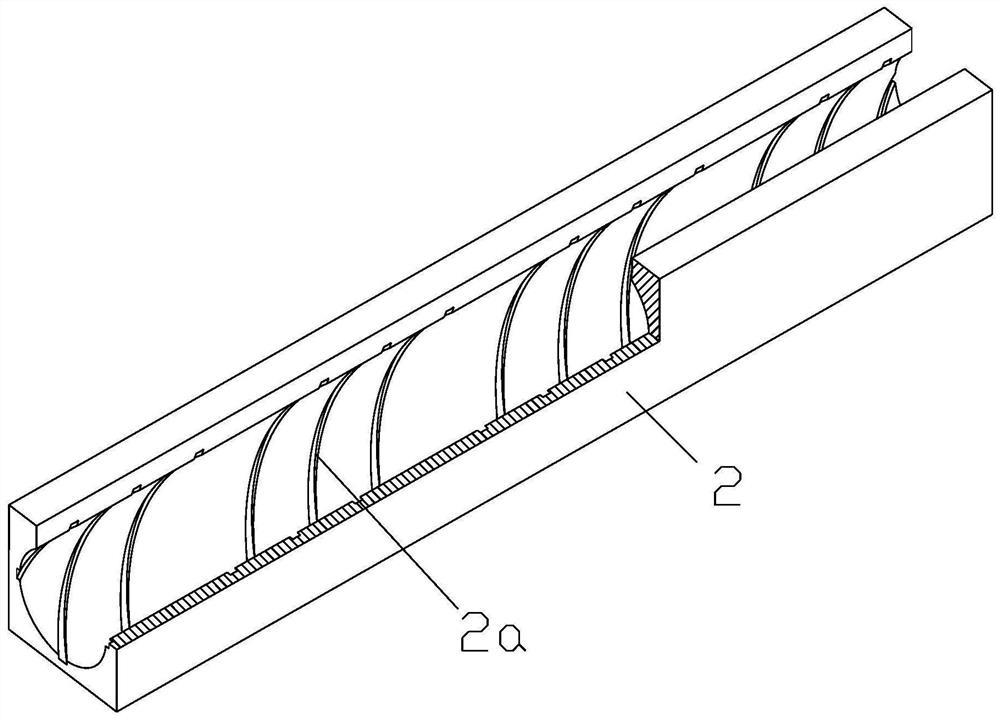

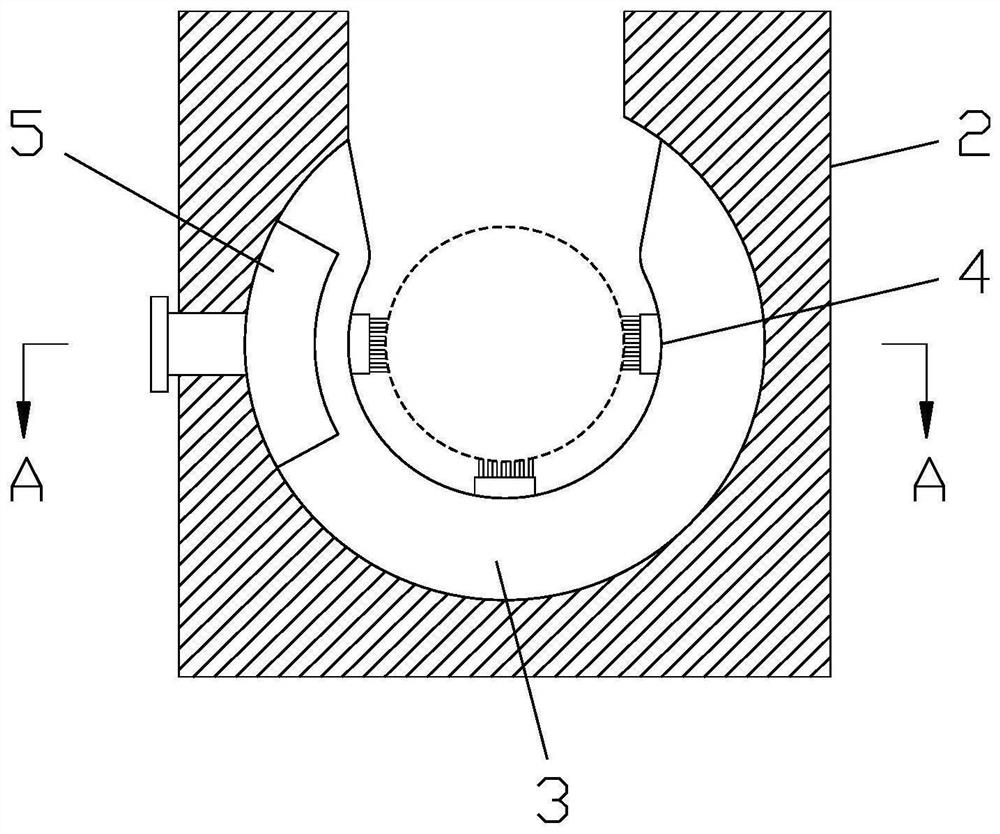

[0055]The fixed bracket 2 is fixedly installed on the base 1, the fixed bracket 2 is horizontally provided with a mounting groove with a first opening at the top, and the inner wall of the mounting groove is provided with a spiral slide rail 2a;

[0056] The movable support 3 is arranged in the installation groove, the outer wall of the movable support 3 is provided with a slide block 34 adapted to the spiral slide rail 2a, and the movable support 3 is horizontally provided with a coating groove, The coating tank has a second opening adapted to the first opening, and the movable suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com