Calibration method for mass flow meters of plate PECVD equipment

A mass flow meter and calibration method technology, applied in the field of mass flow meter calibration, can solve problems such as low precision, deviation between actual flow and set value, inability to accurately control the thickness of SiNx film, etc., to ensure the coating effect, and the operation is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

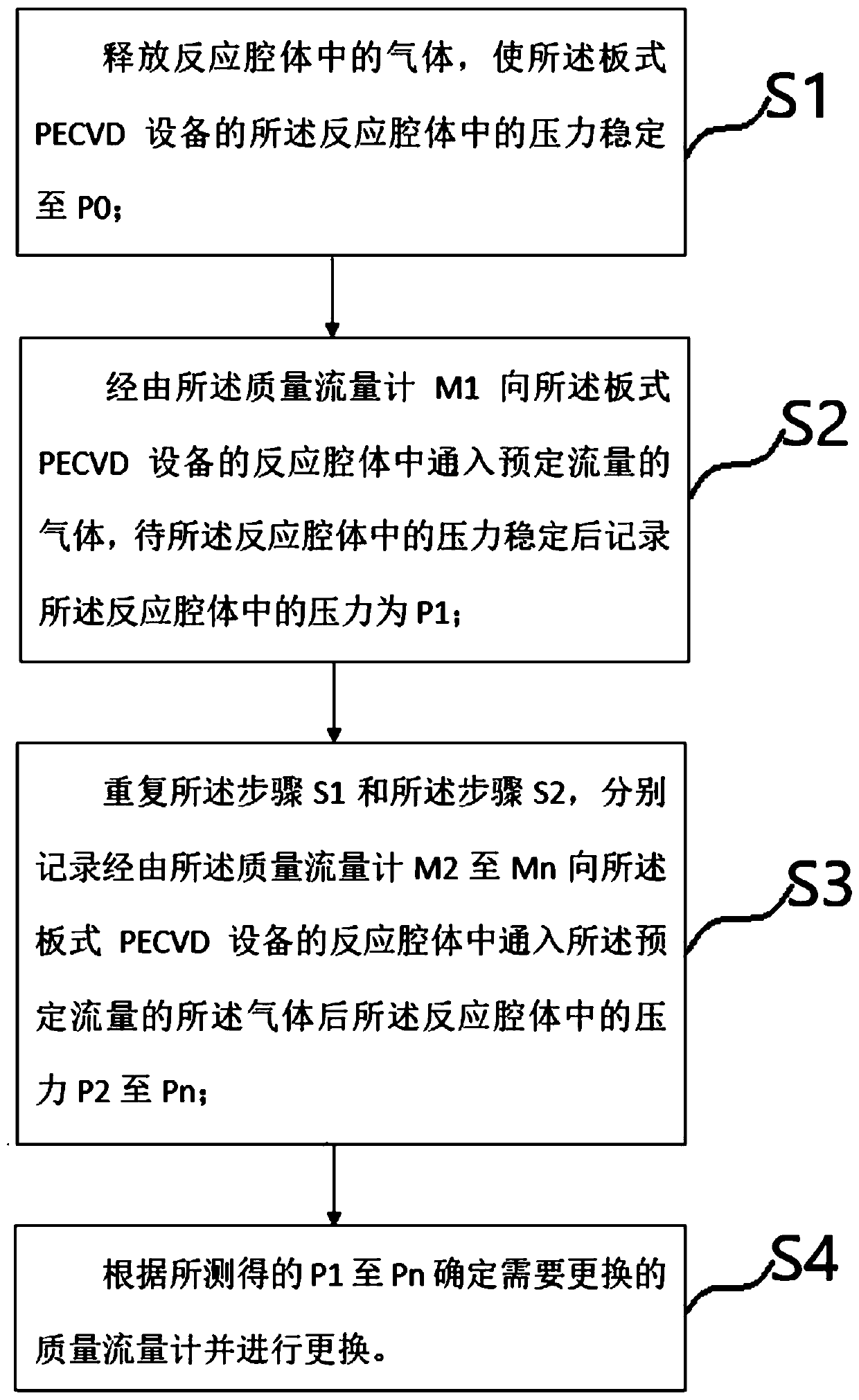

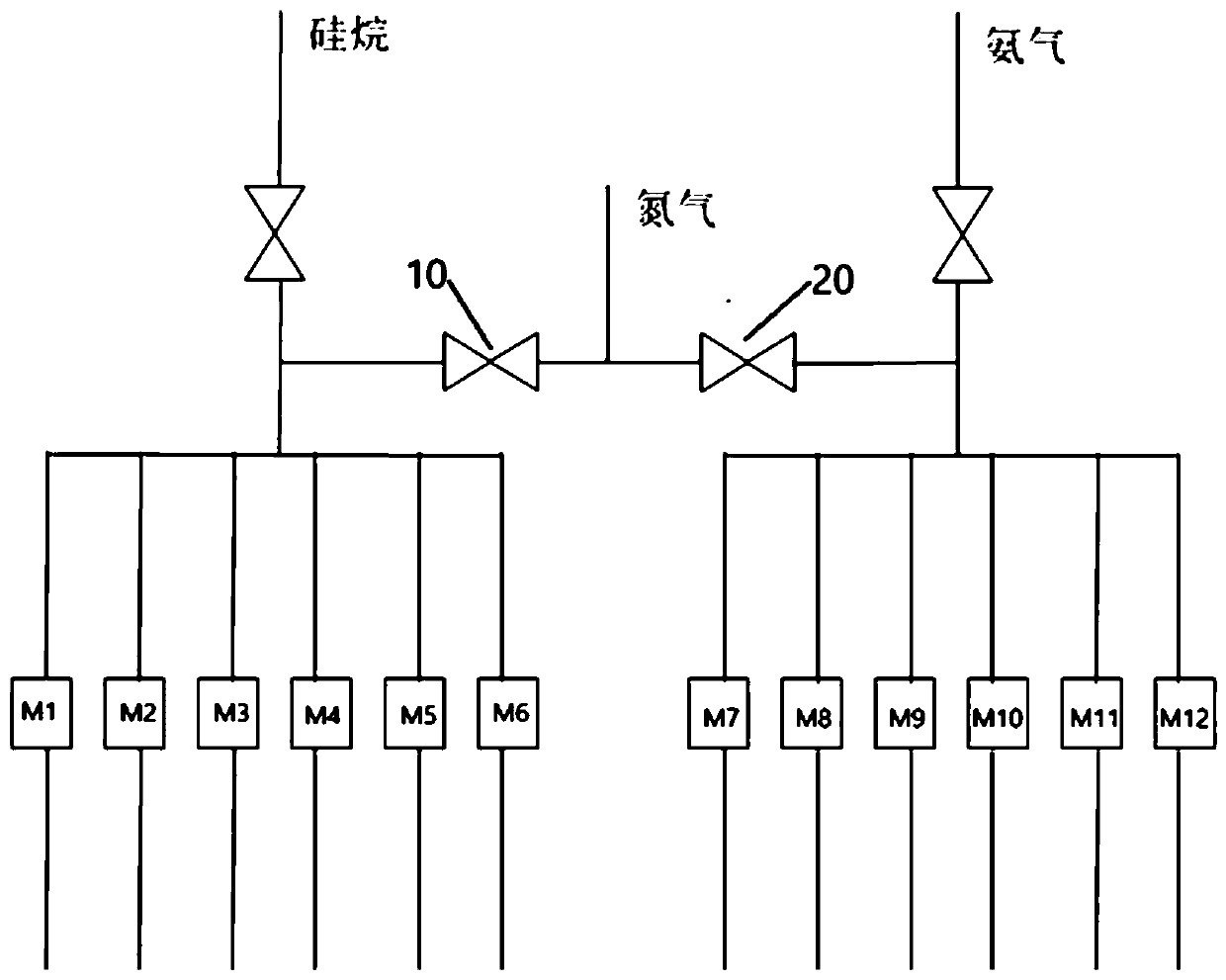

[0027] Such as figure 1 As shown, according to the calibration method of the mass flowmeter of the plate-type PECVD equipment of the embodiment of the present invention, the plate-type PECVD equipment includes mass flowmeters M1 to Mn, wherein, n is a natural number greater than 3, and the calibration method includes the following steps:

[0028] Step S1, releasing the gas in the reaction chamber to stabilize the pressure in the reaction chamber of the plate PECVD equipment to P0;

[0029] According to some embodiments of the present invention, step S1 specifically includes: depressurizing the reaction chamber of the plate-type PECVD equipment, so that the pressure in the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com