Production method for leather-like paper

A production method and leather technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of delamination and high production cost, and achieve the effect of easy cutting, low production cost, and no influence on touch and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

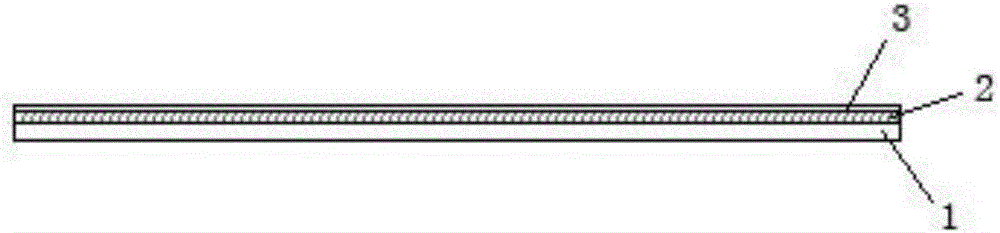

[0038] This embodiment provides a leather-like paper, which has a white board paper layer 1, a carboxylated styrene-butadiene latex layer 2 and a polyurethane synthetic leather layer 3 from bottom to top;

[0039] Prepared by:

[0040] S1: Use white board paper as the bottom layer, and coat carboxylated styrene-butadiene latex on the white board paper;

[0041] S2: heating and drying the coating layer of carboxylated styrene-butadiene latex to form a film, and drying the coating layer of carboxylated styrene-butadiene latex at a temperature of 80°C for 30 minutes;

[0042] S3: Coating polyurethane synthetic leather slurry on the carboxylated styrene-butadiene latex film;

[0043] S4: drying the polyurethane synthetic leather slurry coating layer to obtain imitation leather paper, and drying the polyurethane synthetic leather slurry coating layer at a temperature of 100° C. for 15 minutes.

[0044] In the S1 step, in the preparation monomer of carboxylated styrene-butadiene l...

Embodiment 2

[0048] This embodiment provides a leather-like paper, which has a white board paper layer 1, a carboxylated styrene-butadiene latex layer 2 and a polyurethane synthetic leather layer 3 from bottom to top;

[0049] Prepared by:

[0050] S1: Use white board paper as the bottom layer, and coat carboxylated styrene-butadiene latex on the white board paper;

[0051] S2: heating and drying the coating layer of carboxylated styrene-butadiene latex to form a film, and drying the coating layer of carboxylated styrene-butadiene latex at a temperature of 85°C for 25 minutes;

[0052] S3: Coating polyurethane synthetic leather slurry on the carboxylated styrene-butadiene latex film;

[0053] S4: drying the polyurethane synthetic leather slurry coating layer to obtain imitation leather paper, and drying the polyurethane synthetic leather slurry coating layer at a temperature of 110° C. for 11 minutes.

[0054] In the S1 step, in the preparation monomer of carboxylated styrene-butadiene l...

Embodiment 3

[0058] This embodiment provides a leather-like paper, which has a white board paper layer 1, a carboxylated styrene-butadiene latex layer 2 and a polyurethane synthetic leather layer 3 from bottom to top;

[0059] Prepared by:

[0060] S1: Use white board paper as the bottom layer, and coat carboxylated styrene-butadiene latex on the white board paper;

[0061] S2: heating and drying the coating layer of carboxylated styrene-butadiene latex to form a film, and drying the coating layer of carboxylated styrene-butadiene latex at a temperature of 90°C for 20 minutes;

[0062] S3: Coating polyurethane synthetic leather slurry on the carboxylated styrene-butadiene latex film;

[0063] S4: drying the polyurethane synthetic leather slurry coating layer to obtain imitation leather paper, and drying the polyurethane synthetic leather slurry coating layer at a temperature of 120° C. for 8 minutes.

[0064] In the S1 step, in the preparation monomer of carboxylated styrene-butadiene la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com