Production technique of three-coat color-coated steel plate

A technology of color-coated steel plate and production process, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of reporting and recording the production process of three-coated products, achieve good adhesion, save equipment and space, cost reduction effect

Inactive Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in the literature and patents published at home and abroad, there are no reports and records about the production process of three-coat products produced on two-coat and two-dry units.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

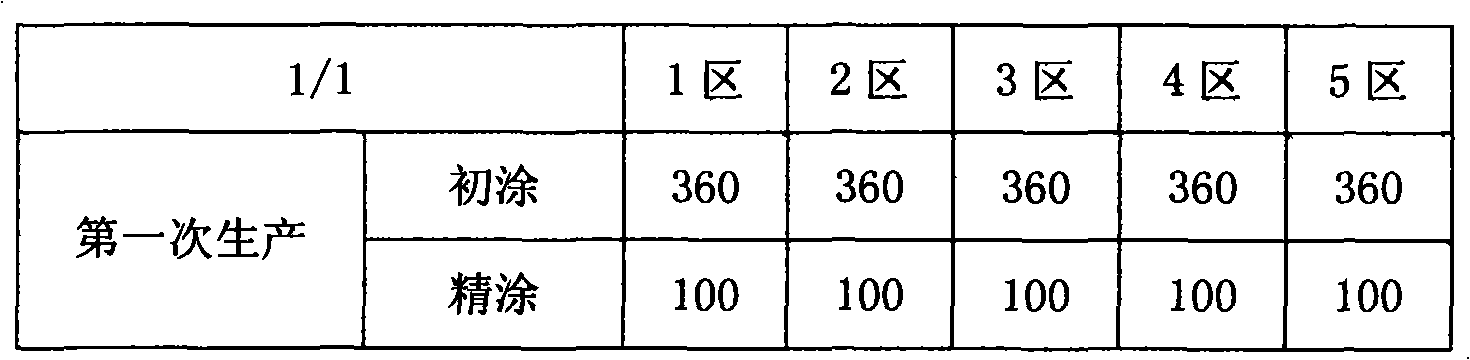

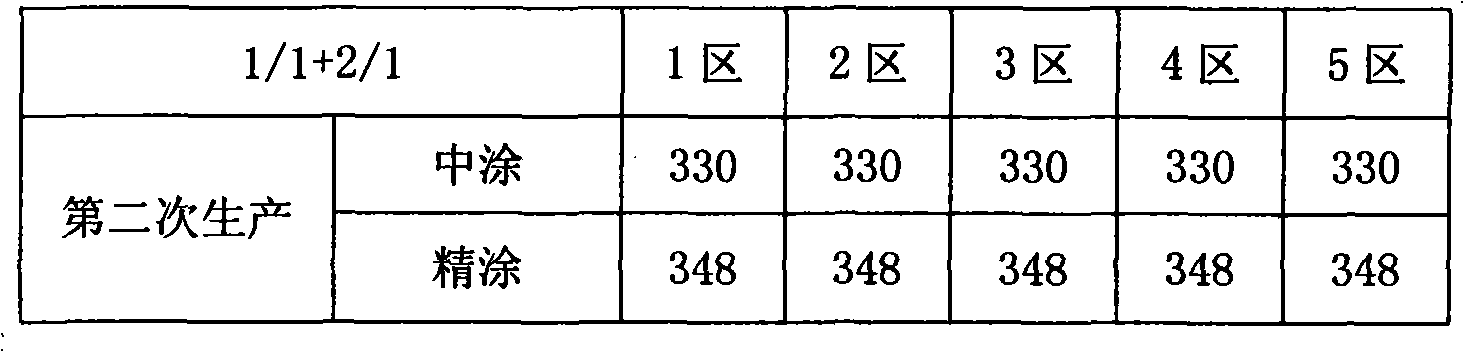

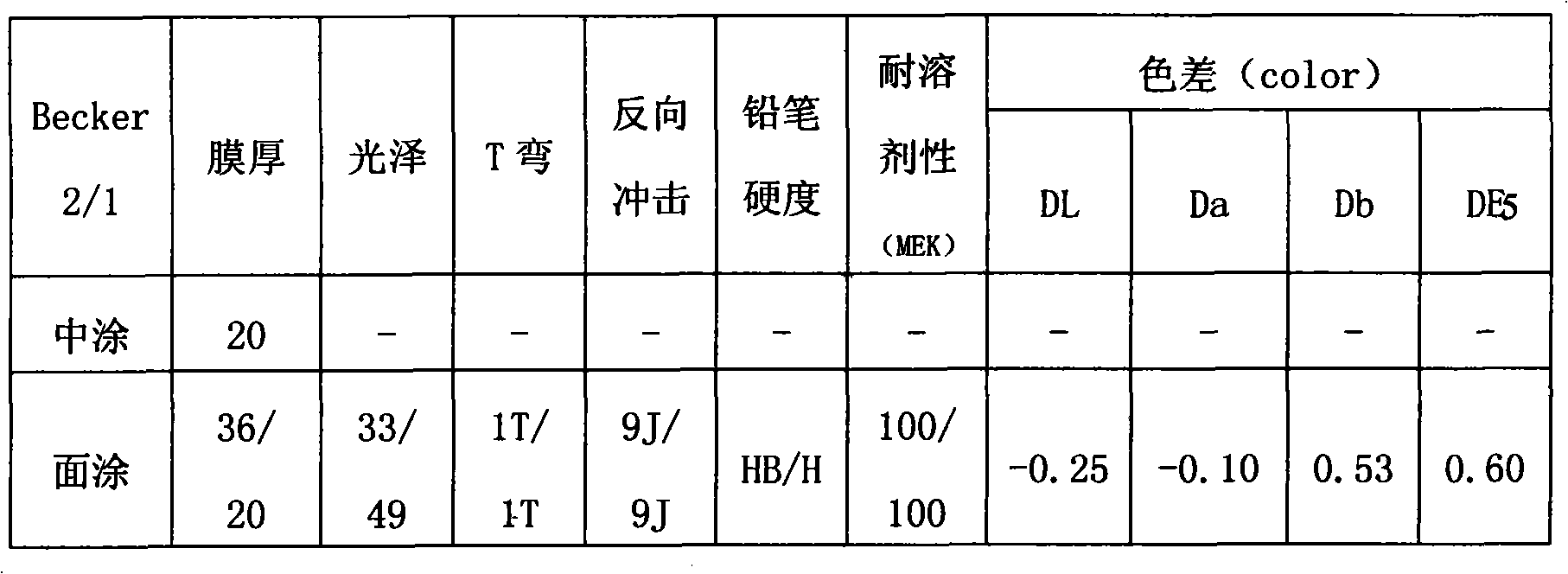

The invention provides a production technique of a three-coat color-coated steel plate, which is characterized in that the steel plate is produced through a double-coat double-bake color-coated machine set by the following steps: (1) primary production: uncoiling a basal plate, seaming, degreasing, preprocessing, coating primer, baking, cooling and coiling to complete the primary coat on the front side and the back side of the steel plate; (2) and secondary production: uncoiling, seaming, coating the intermediate paint, baking, cooling, top coating, baking, coiling and coiling to complete the intermediate coat and the surface coat on the front side of the steel plate, and the surface coat on the back side. The invention utilizes the double-coat double-bake machine set to produce the three-coat product, and does not need a special three-coat three-baking machine set, thereby greatly saving equipment and space and reducing the cost; in addition, the technique can accurately control the thickness of the bottom coat, middle coat and face coat, ensure the surface quality and good binding force among the layers during coating the coat, and ensure the comprehensive coat performance after three-coating.

Description

Technical field The invention relates to a color-coated steel sheet, specifically, the invention relates to a production process of a three-coated color-coated steel sheet. Background technique Color-coated steel sheets are currently widely used in industrial plants, stadiums, airport facilities and other construction fields. As building roofs and exterior walls, they provide a beautiful appearance, long life, and are convenient for construction and maintenance. Color-coated steel sheets are mainly divided into 2 / 2 and 2 / 1 according to the surface coating structure, that is, two layers of coating on the front (primer and topcoat), two layers of coating on the back (primer and topcoat) or one layer of coating ; The total coating thickness on the front is generally 20-25μm, and the total coating thickness on the back is generally 5-15μm (the basic structure is shown in Figure 1). Among steel products, the production process of color-coated products is the longest, which mainly i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05D1/38B05D7/14

Inventor 牟战旗任玉苓秦杰王仲庆

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com