Nonwoven fabric for protective clothing and preparation method of non-woven fabric

A non-woven fabric and non-woven fabric-based technology, applied in the field of non-woven fabrics for protective clothing and its preparation, can solve the problems of inability to produce a cool feeling, single function of non-woven fabrics, and discomfort, etc., and achieve long-lasting cooling effect and strong moisture absorption Long-lasting effects of sexuality and coolness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

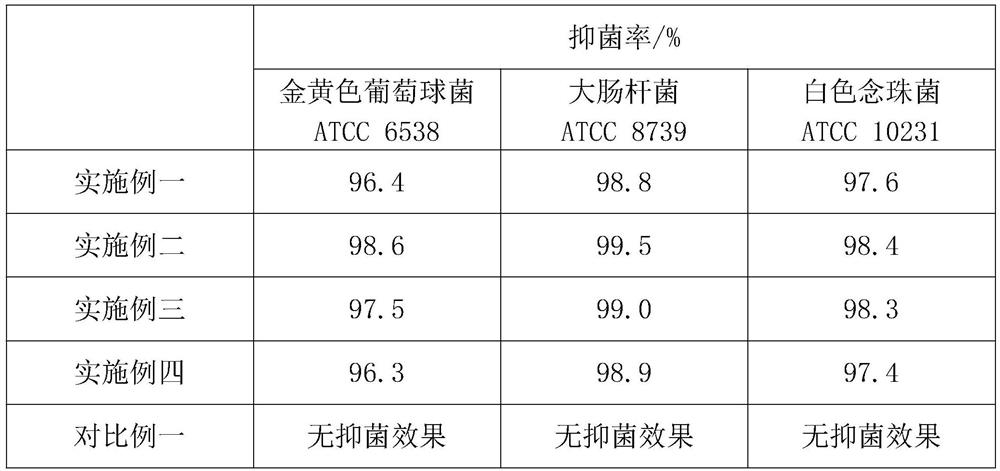

Examples

Embodiment 1

[0023] A non-woven fabric for protective clothing, including a non-woven fabric base material, the non-woven fabric base material is a polypropylene non-woven fabric, and the polypropylene non-woven fabric can be applied to protective clothing after being treated with a microcapsule finishing solution. The microcapsule finishing solution includes the following raw materials in parts by weight: 35 parts by weight of microcapsule emulsion, 6 parts by weight of polycarbodiimide crosslinking agent, 2 parts by weight of carboxymethyl cellulose, and 1.5 parts by weight of fatty alcohol polyoxyethylene ether; Described microcapsule emulsion is to take chitosan and sodium alginate as wall material, xylitol, N-ethyl-L-menthyl formamide, ammonium nitrate are core material, the quality of described chitosan and sodium alginate The ratio is 1:1.8, the mass ratio of the core material to the wall material is 2:1, and the mass ratio of xylitol, N-ethyl-L-menthyl formamide, and ammonium nitrat...

Embodiment 2

[0029] A non-woven fabric for protective clothing, including a non-woven fabric substrate, the non-woven fabric substrate is a polylactic acid non-woven fabric, and the polylactic acid non-woven fabric can be applied to protective clothing after being treated with a microcapsule finishing solution. The microcapsule finishing solution includes the following raw materials in parts by weight: 45 parts by weight of microcapsule emulsion, 9 parts by weight of polycarbodiimide crosslinking agent, 3 parts by weight of carboxymethyl cellulose, and 2 parts by weight of fatty alcohol polyoxyethylene ether; Described microcapsule emulsion is to take chitosan and sodium alginate as wall material, xylitol, N-ethyl-L-menthyl formamide, ammonium nitrate are core material, the quality of described chitosan and sodium alginate The ratio is 1:2.2, the mass ratio of the core material to the wall material is 3:1, and the mass ratio of xylitol, N-ethyl-L-menthyl formamide, and ammonium nitrate is 2...

Embodiment 3

[0035] A non-woven fabric for protective clothing, including a non-woven fabric substrate, the non-woven fabric substrate is a polyvinyl alcohol non-woven fabric, and the polyvinyl alcohol non-woven fabric can be applied to protective clothing after being treated with a microcapsule finishing solution. The microcapsule finishing solution includes the following raw materials in parts by weight: 60 parts by weight of microcapsule emulsion, 12 parts by weight of polycarbodiimide crosslinking agent, 4 parts by weight of carboxymethyl cellulose, and 2.5 parts by weight of fatty alcohol polyoxyethylene ether; Described microcapsule emulsion is to be wall material with chitosan and sodium alginate, xylitol, N-ethyl-L-menthyl formamide is core material, and the mass ratio of described chitosan and sodium alginate is 1 : 2.5, the mass ratio of the core material to the wall material is 4:1, and the mass ratio of xylitol and N-ethyl-L-menthyl formamide is 2:2;

[0036] Wherein the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com