Aqueous two-component wood varnish and application thereof

A water-based two-component, wood varnish technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the high comprehensive cost of two-component water-based wood paint, two-component white varnish thick coating blistering, Increase labor costs and time costs, etc., to achieve the effects of fast drying speed and performance improvement, shortening the construction period, and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

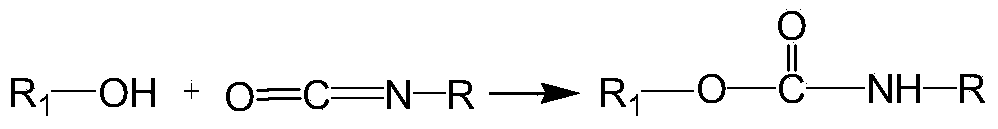

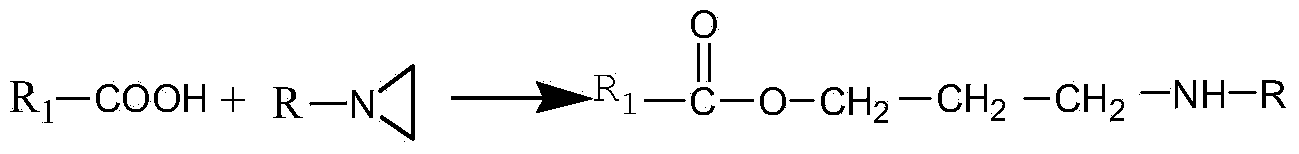

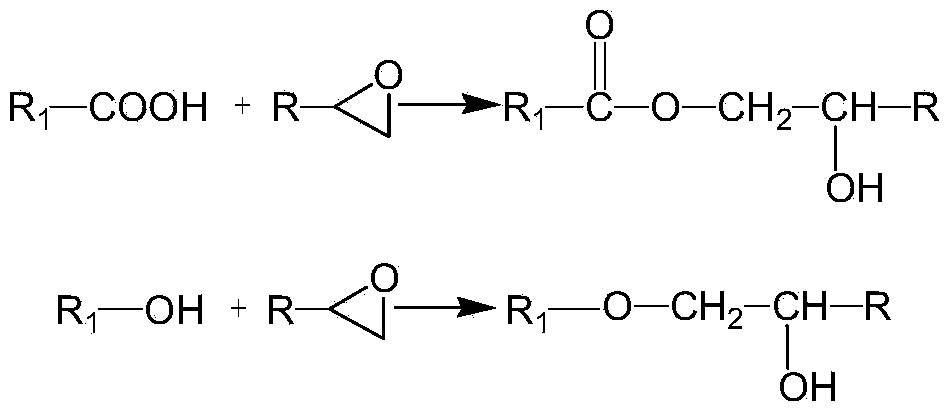

Method used

Image

Examples

Embodiment 1- Embodiment 4

[0082] The formula design of main ingredients is shown in the table below:

[0083]

[0084] Curing agent component formula design is as follows:

[0085]

Embodiment 5- Embodiment 8

[0087] The formula design of main ingredients is shown in the table below:

[0088]

[0089] Curing agent component formula design is as follows:

[0090]

[0091]

Embodiment 1

[0092] Example 1-Example 3 Bayer's Bayhydrol A2427 was used as the film former to prepare the main agent component, and Bayer's Bayhydur XP2655 was used as the curing agent to prepare the curing agent component. The mass ratio of main agent component and curing agent component in each embodiment is as follows in construction: embodiment 1 main agent: curing agent is 100:9, embodiment 2 main agent: curing agent is 100:9, embodiment 3 main agent : The curing agent is 100:10. During construction, mix the main agent components and curing agent components of each example according to the above proportions, and add 0% to 10% of water to adjust the viscosity of the two-component coating to 20″~30″ according to the caliber of the spray gun and other construction conditions. , to spray. The construction base material requirement is the laminated board or solid wood board that has been coated with primer, primer can be common one-component water-based wood varnish primer, also can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com