Flue-cured tobacco mildew preventive

A technology of antifungal agent and flue-cured tobacco, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve problems such as no anti-mold method has been found, achieve good promotion and application value and economic benefits, improve smoldering property, and have good anti-mold effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

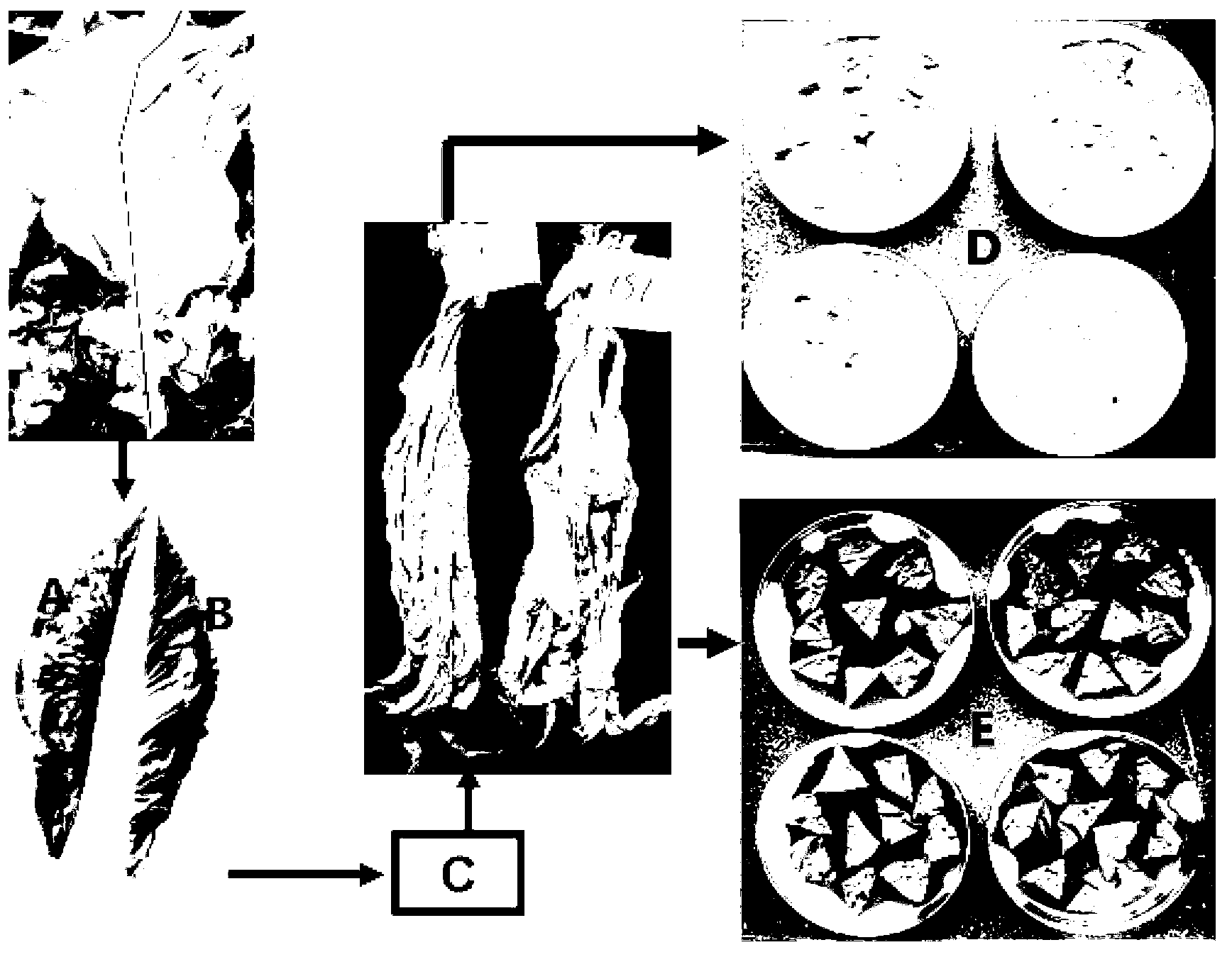

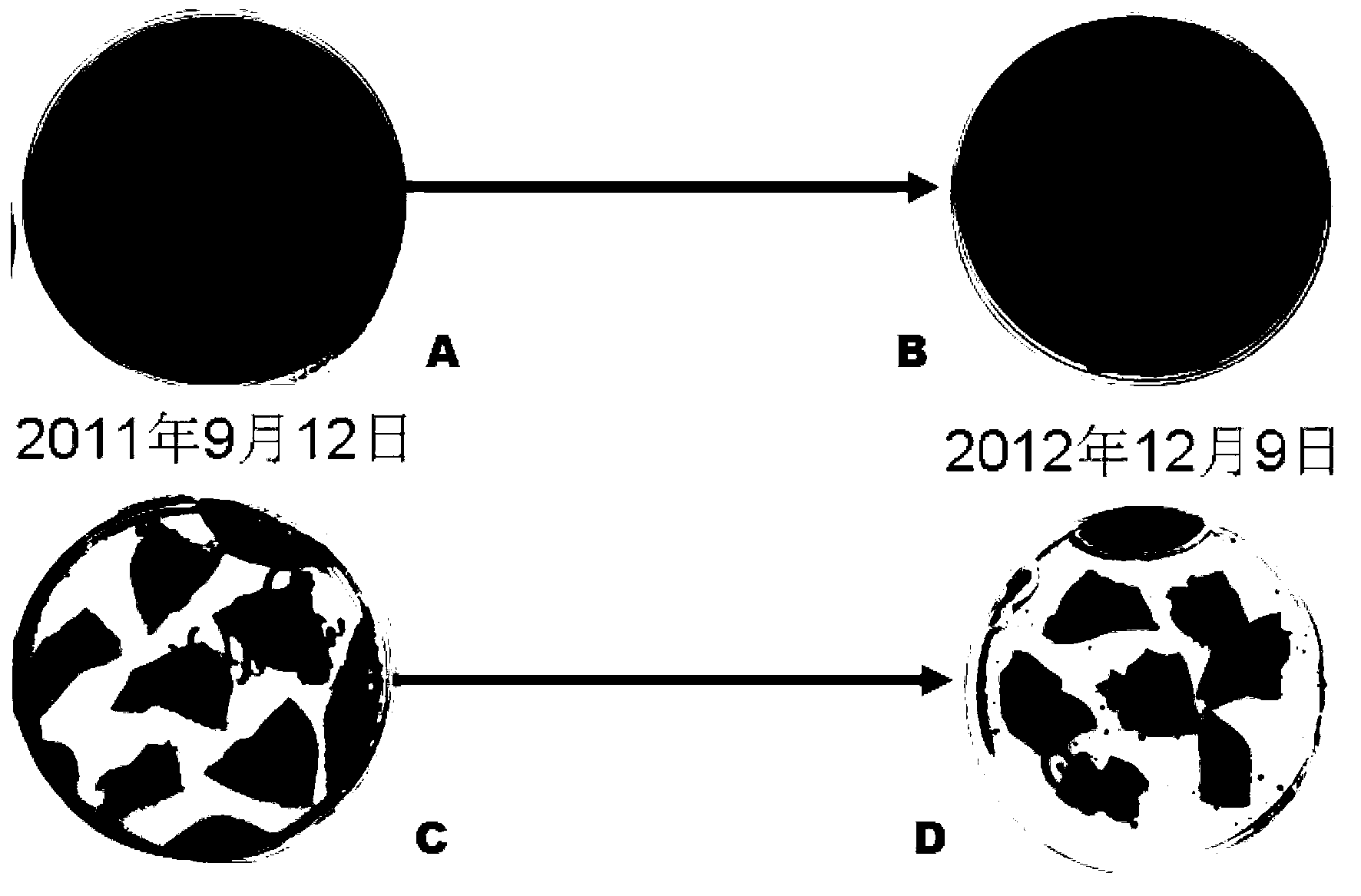

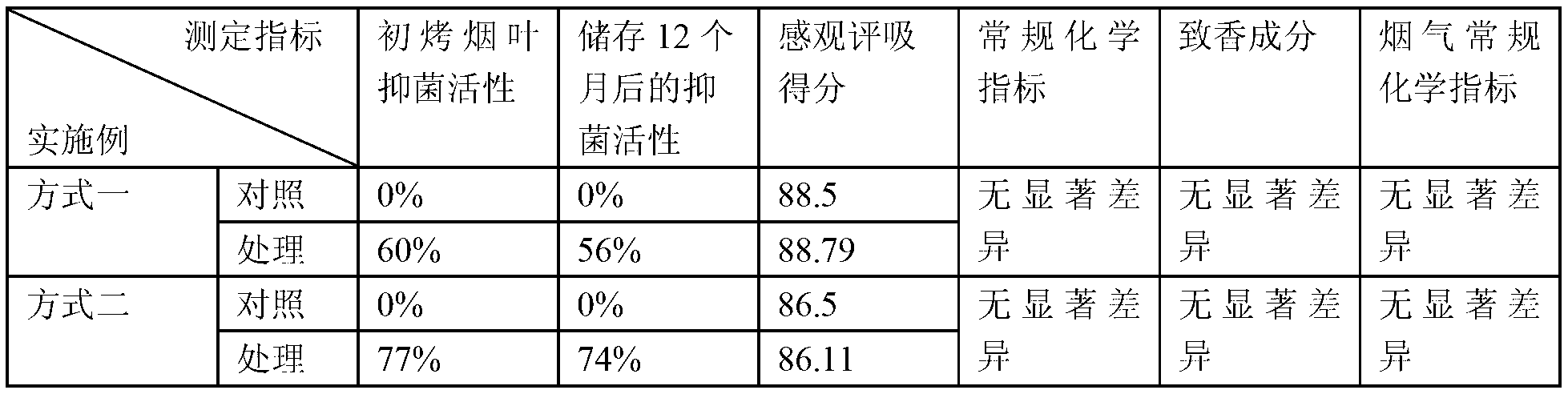

Embodiment 1

[0017] 50 grams of natamycin accounting for 0.005% by weight and 200 grams of potassium citrate accounting for 0.02% by weight were dissolved in 999.75 kg of water and stirred evenly to obtain the required antifungal agent. Use a sprayer to evenly spray the above solution to the fresh tobacco leaves that have been braided and ready to enter the barn. After the kang is installed, the conventional three-step baking process is used for initial baking, so that the tobacco leaves can obtain resistance to mildew microorganisms. sex.

Embodiment 2

[0019] 50 grams of natamycin accounting for 0.005% by weight and 200 grams of potassium citrate accounting for 0.02% by weight were dissolved in 999.75 kg of water and stirred evenly to obtain the required antifungal agent. Soak the fresh tobacco leaves that have been braided and ready to enter the barn in the antifungal agent for 10 minutes. After draining, put them on the kang for initial baking according to the conventional three-step baking process, so that the tobacco leaves can acquire resistance to mildew microorganisms.

Embodiment 3

[0021] Dissolve 250 grams of 0.025% by weight of natamycin and 400 grams of 0.04% by weight of potassium citrate in 999.35 kg of water, and stir evenly to obtain the desired antifungal agent. Use a sprayer to evenly spray the above solution to the fresh tobacco leaves that have been braided and ready to enter the barn. After the kang is installed, the conventional three-step baking process is used for initial baking, so that the tobacco leaves can obtain resistance to mildew microorganisms. sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com