Mildew-proof silane modified polyurethane sealant and preparation method thereof

A technology of polyurethane sealant and silane modification, applied in the field of sealant, can solve the problems of easy mildew, easy yellowing, and anti-mildew failure on the surface of the colloid, so as to improve the oxidation resistance and yellowing resistance, and improve the stability of the molecular structure. , lasting effect of anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

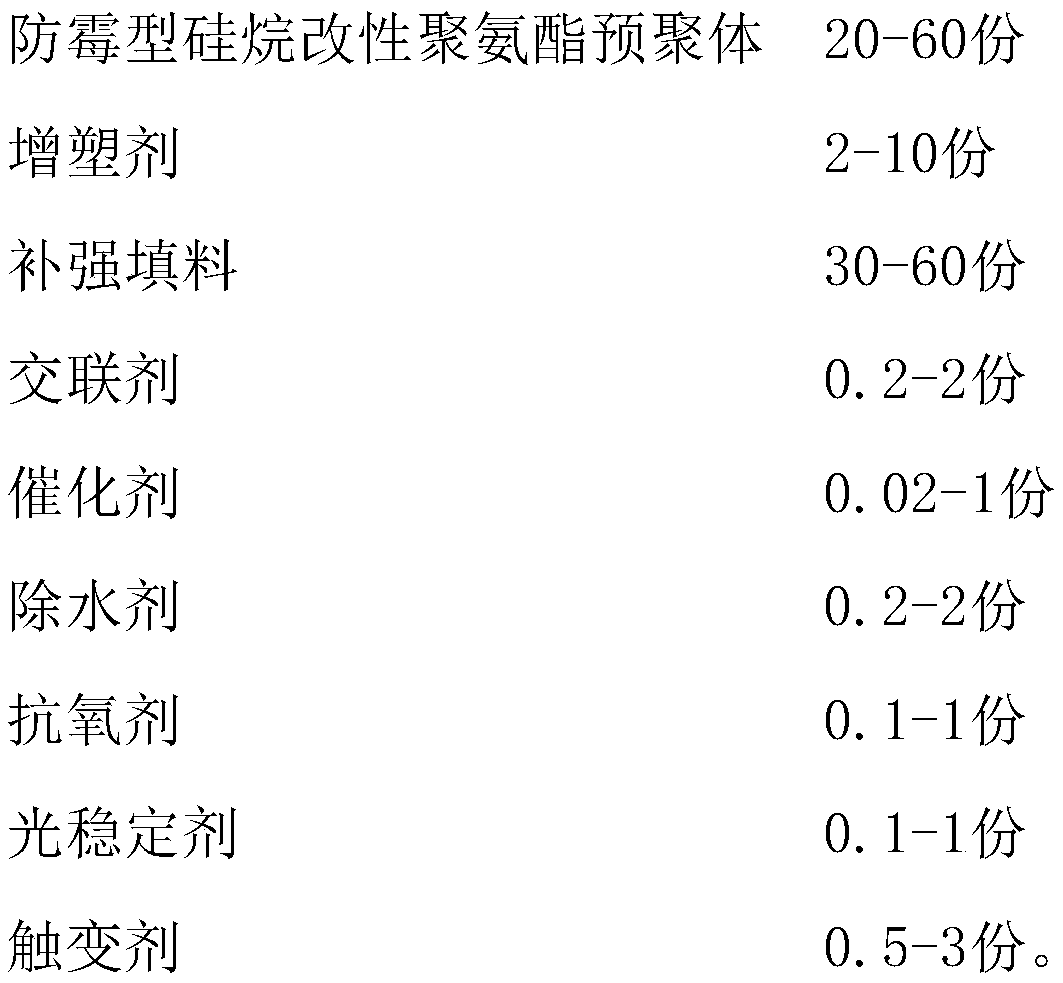

[0039] A mildew-resistant silane-modified polyurethane sealant, comprising the following raw materials in parts by weight:

[0040]

[0041] The reinforcing filler is 12 parts of ground calcium carbonate, 10 parts of talcum powder and 28.5 parts of active calcium carbonate.

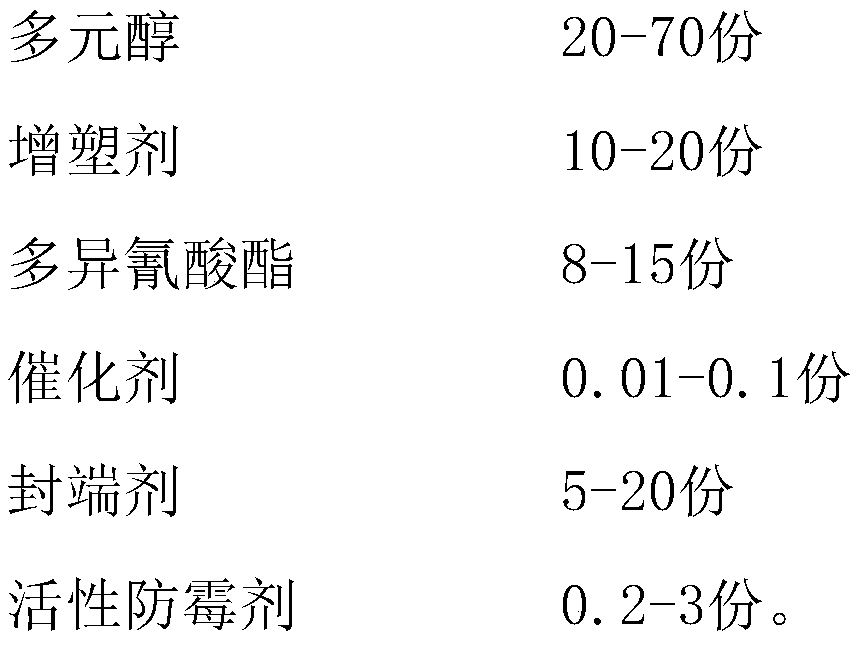

[0042] The mold-proof silane-modified polyurethane prepolymer includes the following raw materials in parts by weight:

[0043]

[0044] The mold-proof silane-modified polyurethane prepolymer is prepared by the following steps:

[0045] In parts by weight, polyoxypropylene diol, polyoxypropylene triol and dioctyl phthalate were added to a vacuum reaction device, dehydrated under vacuum conditions at a temperature of 108°C for 1.5 hours, and the moisture content of the mixture was controlled to be 150ppm; Then lower the temperature to 85°C, add dicyclohexylmethane diisocyanate and stannous octoate under the condition of nitrogen protection, and mix the reaction for 4 hours; finally, at a temperature...

Embodiment 2

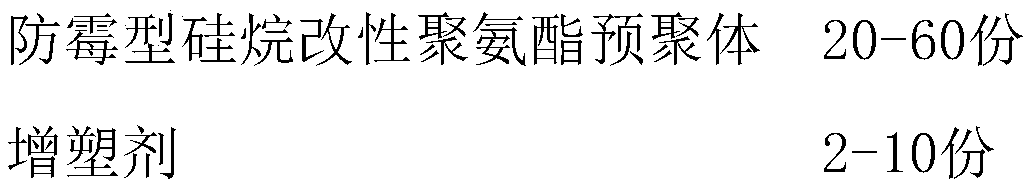

[0049] A mildew-resistant silane-modified polyurethane sealant, comprising the following raw materials in parts by weight:

[0050]

[0051] The reinforcing filler is 10 parts of kaolin, 20 parts of active calcium carbonate and 18 parts of silicon micropowder.

[0052] The mold-proof silane-modified polyurethane prepolymer includes the following raw materials in parts by weight:

[0053]

[0054] The mold-proof silane-modified polyurethane prepolymer is prepared by the following steps:

[0055] In parts by weight, polyoxypropylene diol, polyoxypropylene triol and dioctyl phthalate were added to a vacuum reaction device, dehydrated under vacuum conditions at a temperature of 109°C for 1.8 hours, and the moisture content of the mixture was controlled to be 135ppm; Then lower the temperature to 90°C, add dicyclohexylmethane diisocyanate and stannous octoate under the condition of nitrogen protection, and mix and react for 5.5 hours; finally, at a temperature of 94°C, add γ...

Embodiment 3

[0059] A mildew-resistant silane-modified polyurethane sealant, comprising the following raw materials in parts by weight:

[0060]

[0061] The reinforcing filler is 11 parts of heavy calcium carbonate, 23 parts of light calcium carbonate and 17 parts of silicon micropowder.

[0062] The mold-proof silane-modified polyurethane prepolymer includes the following raw materials in parts by weight:

[0063]

[0064]

[0065] The mold-proof silane-modified polyurethane prepolymer is prepared by the following steps:

[0066] In parts by weight, polyoxypropylene diol, polyoxypropylene triol and dioctyl phthalate were added to a vacuum reaction device, dehydrated under vacuum conditions at a temperature of 108°C for 2 hours, and the moisture content of the mixture was controlled to be 185ppm; then Cool down to 93°C, add hexamethylene diisocyanate and dibutyltin diacetate under nitrogen protection conditions, mix and react for 5 hours; finally add γ-aminopropyltrimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com