Patents

Literature

74results about How to "Eliminate pinholes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane anti-corrosion priming paint sprayed on steel structure in abyssal environment

InactiveCN102676029AEliminate pinholesAvoid damageAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention relates to a polyurethane anti-corrosion priming paint sprayed on a steel structure in an abyssal environment. The priming paint is polyurethane modified epoxy solvent-free priming paint; after being subjected to polyurethane modification, the epoxy solvent-free priming paint has higher compressive strength than a common solvent-free epoxy coating, and has higher adhesion strength with the steel structure and sprayed polyurethane. After the matching of the polyurethane modified epoxy solvent-free priming paint and the spray polyurethane, the drawing strength between the whole coating and the steel structure is tested to be larger than or equal to 10 MPa. The polyurethane modified epoxy solvent-free priming paint solves the problems of low compressive strength and polyurea adhesion strength of the common solvent-free epoxy priming paint used in the abyssal environment, and also solves the problem of low steel structure adhesion strength of a polyurethane type priming paint in the abyssal environment.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Method for recovering nickel in chemical nickel-plating ageing liquid

ActiveCN102212842AImprove wettabilityConvenient and quick escapePhotography auxillary processesThioureaPolyethylene glycol

The invention discloses a method for recovering nickel in a chemical nickel-plating ageing liquid, and the method comprises the following steps: (1) adding 1100-1300 parts by weight of the chemical nickel-plating ageing liquid into an electrolytic cell, and regulating the pH value of the ageing liquid to 8-10 by use of solid sodium hydroxide; (2) dissolving 0.01-0.03 part by weight of polyethylene glycol, 0.01-0.02 part by weight of 2-mercapto benzimidazole, 0.03-0.06 part by weight of thiourea, 0.005-0.03 part by weight of hide glue and 0.3-0.5 part by weight of sodium hypophosphite into 40-70 parts by weight of water, adding the mixture into the electrolytic cell, and adding 1-3 parts by weight of 5mol / L hydrochloric acid solution; (3) at normal temperature, on the basis of taking a stainless steel plate as a cathode and a reticular plate plated with iridium oxide titanium alloy as an anode, reacting for 8-10 hours at constant reaction current of 0.6-1.0A, thus obtaining a recoveredmetal nickel on the cathode. The method has the advantages of high recovery rate, simple equipment, low cost and the like, works at normal temperature and is easy to realize.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Preparation method of intermediate-temperature magnesium strengthening porcelain and product prepared from intermediate-temperature magnesium strengthening porcelain

The invention relates to a preparation method of an intermediate-temperature magnesium strengthening porcelain and a product prepared from the intermediate-temperature magnesium strengthening porcelain. The formula of the strengthening porcelain comprises the following billet materials and glaze materials by weight percent: the billet materials: 30% to 45% of sintered talc, 20% to 35% of raw talc, 5% to 15% of feldspar, 10% to 18% of kaolin, 3% to 5% of bentonite and 0% to 15% of quartz; the glaze materials: 20% to 40% of feldspar, 5% to 15% of calcite, 4% to 8% of kaolin, 0% to 15% of quartz, 3% to 5% of ZnO, 3% to 5% of BaCO and 20% to 35% of glass materials. The preparation method comprises the following steps: carrying preparation, molding, drying, billet biscuiting, glazing, drying and intermediate-temperature glaze firing on the billet materials and the glaze materials under the conditions that the biscuiting temperature of a billet is controlled within 1240 DEG C to 1260 DEG C, the heat preservation time of the billet is 30 minutes, the firing time of an intermediate-temperature glaze is 1100 DEG C and the firing time of the intermediate-temperature glaze is 30 minutes, thereby obtaining the strengthening porcelain with a good glaze surface quality and a high glossiness. Thus, the method has a wide application prospect.

Owner:JIANGXI GALOBAL CERAMIC CO LTD

Polyurethane resin for high-density shoe leather and preparation method thereof

ActiveCN102181034ALow costGood softness at low temperatureTextiles and paperN dimethylformamidePolymer science

The invention relates to wet-process polyurethane resin for high-density shoe leather. The polyurethane resin is prepared from isocyanate, a polyether polyol mixture, a chain extender and N, N-dimethylformamide serving as an organic solvent. Polyoxytetramethylene-ethylene epoxide copolyether diol and polyoxypropylene diol are taken as macromolecular polylol raw materials for reacting, the raw materials have high hydrolysis resistance and the polyurethane resin can be endowed with high low-temperature flexibility and rebound resilience, so that the prepared high-density shoe leather has finer folds, high durability and high low-temperature adaptability, and recovers quickly. On the aspect of synthesis technology, a special process for stepwise reaction of two polyether polyols is designed,so that a macromolecular structure is more regular, and advantages of the two polyether polyols can be brought into play.

Owner:SHANGHAI HUIDE TECH CO LTD

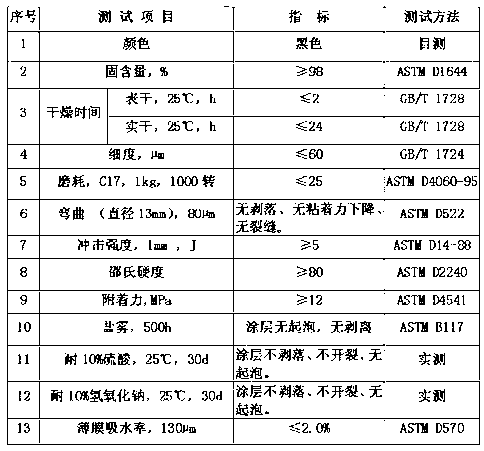

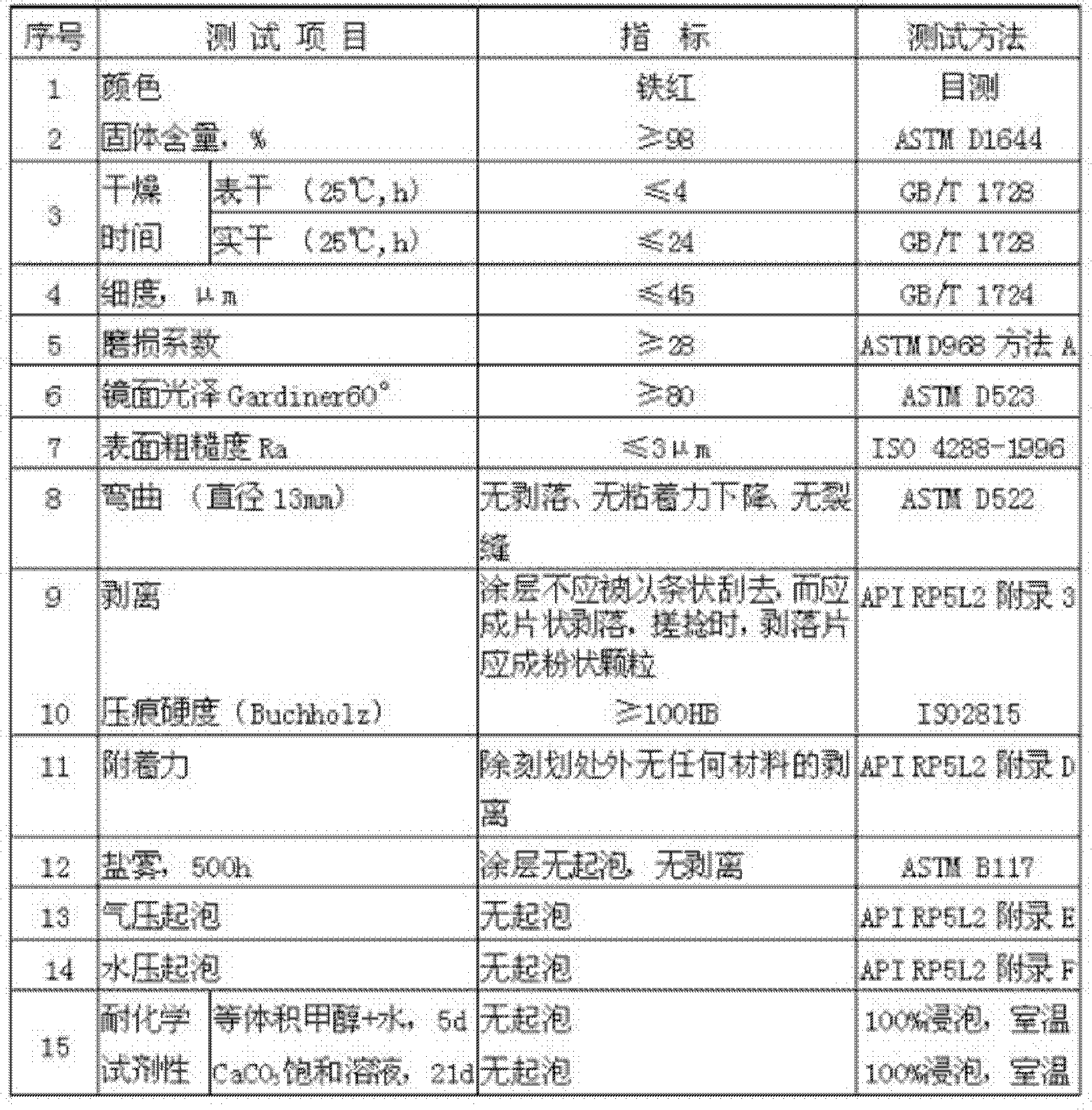

Solvent-free anticorrosive coating for directionally-drilled pipelines and preparation method for same

ActiveCN102993913AImprove wear resistanceImprove scratch resistanceAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention relates to a solvent-free anticorrosive coating for directionally-drilled pipelines and a preparation method for the same, wherein the solvent-free anticorrosive coating comprises a constituent A and a constituent B; the raw materials of the constituent A contain epoxy resin, an activated thinning agent, an anti-settling thickening agent, a levelling agent, a defoaming agent, a dispersing agent, polytetrafluoroethylene wax, ultrahard wear-resistant powder, graphite, molybdenum disulfide, talcum powder, zinc aluminium orthophosphate hydrate and strontium aluminium polyphosphate hydrate; the raw materials of the constituent B contain home-made amine which is a phenolic modified fatty amine epoxy resin curing agent, and a thixotropic thickening agent; the constituent A and the constituent B are used together in a ratio of (4 to 6): 1 by mass; and the preparation method comprises the following steps of: (1) preparing raw materials, (2) proportioning and dispersing, (3) grinding, and (4) filtering and packaging. The solvent-free anticorrosive coating disclosed by the invention is free from a volatile solvent, easy to coat, capable of eliminating the pinholes of the coating, improved in permeability resistance, wear resistance and corrosion resistance, and suitable for being applied to directionally-drilled pipelines.

Owner:海隆石油产品技术服务(上海)有限公司

Investment casting pouring method of thin-wall aluminum alloy casting

InactiveCN104493090AEliminate pinholesEliminate shrinkage defectsFoundry mouldsFoundry coresInvestment castingAlloy

The invention discloses an investment casting pouring method of a thin-wall aluminum alloy casting. In the method, before casting pouring, a formwork is heated to a relatively high temperature (700+ / -50 DEG C), so that the cooling speed of alloy liquid is reduced, and the alloy liquid can completely fill a formwork cavity for sure so as to obtain a casting with a qualified shape; and moreover, the poured casting is taken out of the formwork and then immediately put on a cooling bracket to be forcibly and quickly cooled, and thus the defects of pinholes and shrinkage porosity of the casting can be eliminated.

Owner:GUIZHOU HONGLIN MACHINERY

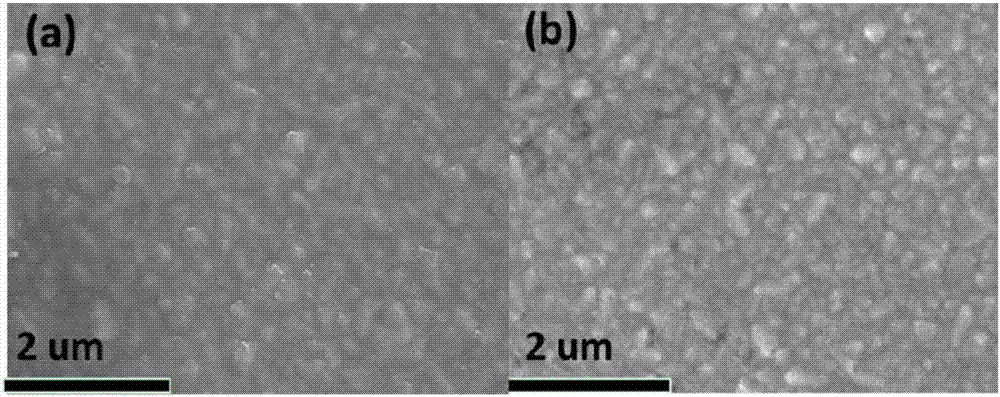

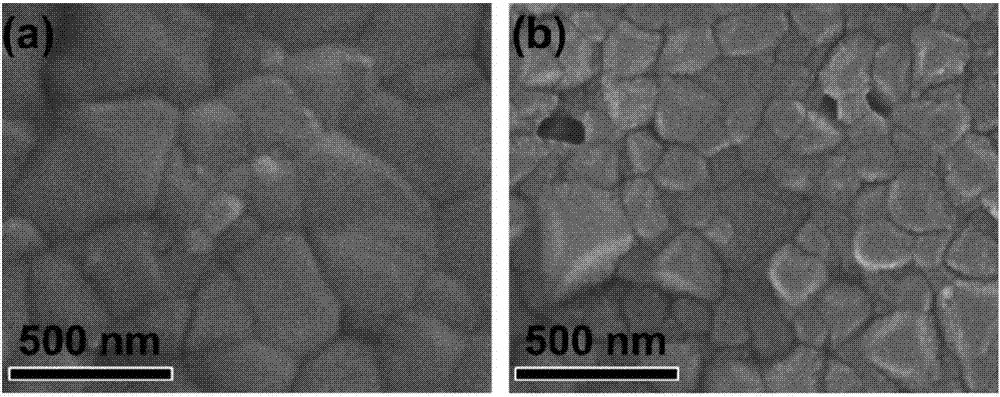

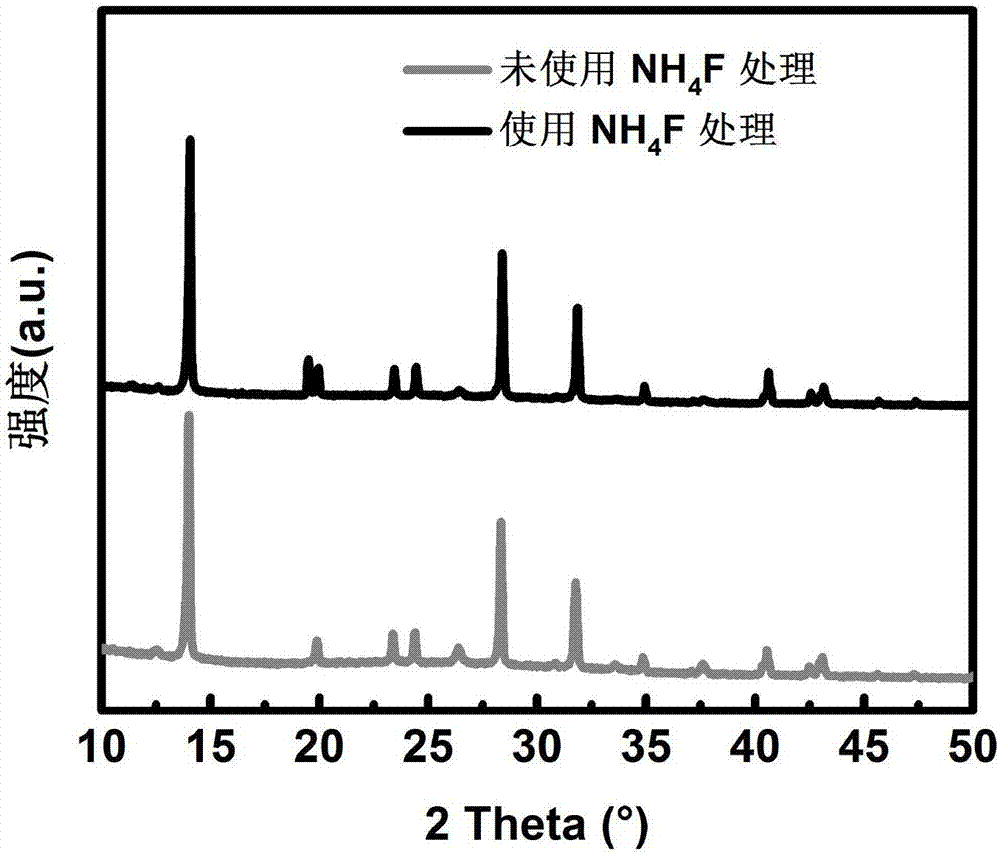

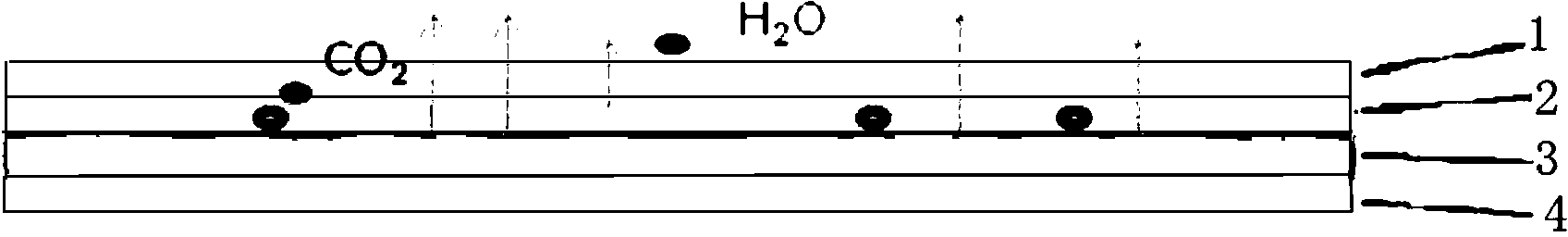

Method utilizing ammonium fluoride solution to treat electron transmission layer of perovskite cell

ActiveCN107068874AImprove photoelectric conversion performanceImprove electron extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellIodide

The invention provides a method utilizing ammonium fluoride solution to treat an electron transmission layer of a perovskite cell and belongs to the treatment method technology field of the electron transmission layer of the cell. Prepared titanium dioxide precursor solution is coated on conductive glass, a coated film is transferred to a muffle furnace with temperature of 450-550 DEG C, sintering is carried out for 25-35 min, the prepared titanium dioxide film is dipped in solution for 0.1-3min to carry out ammonium fluoride surface modification treatment, the treated film is cleaned through utilizing ion water for 3-5 times and is then dried for 18-23 min under the temperature of 95-105 DEG C, and a titanium dioxide film treated through ammonium fluoride is acquired; isopropanol solution of methylamino iodide is coated on a prepared lead iodide film to prepare a perovskite film, a device coated with a cavity transmission layer material is disposed in the air for non-light oxidation for 24 hours, vapor plating of a 60nm Au electrode is carried out through utilizing vacuum vapor plating, and the acquired perovskite cell is then tested.

Owner:HARBIN INST OF TECH

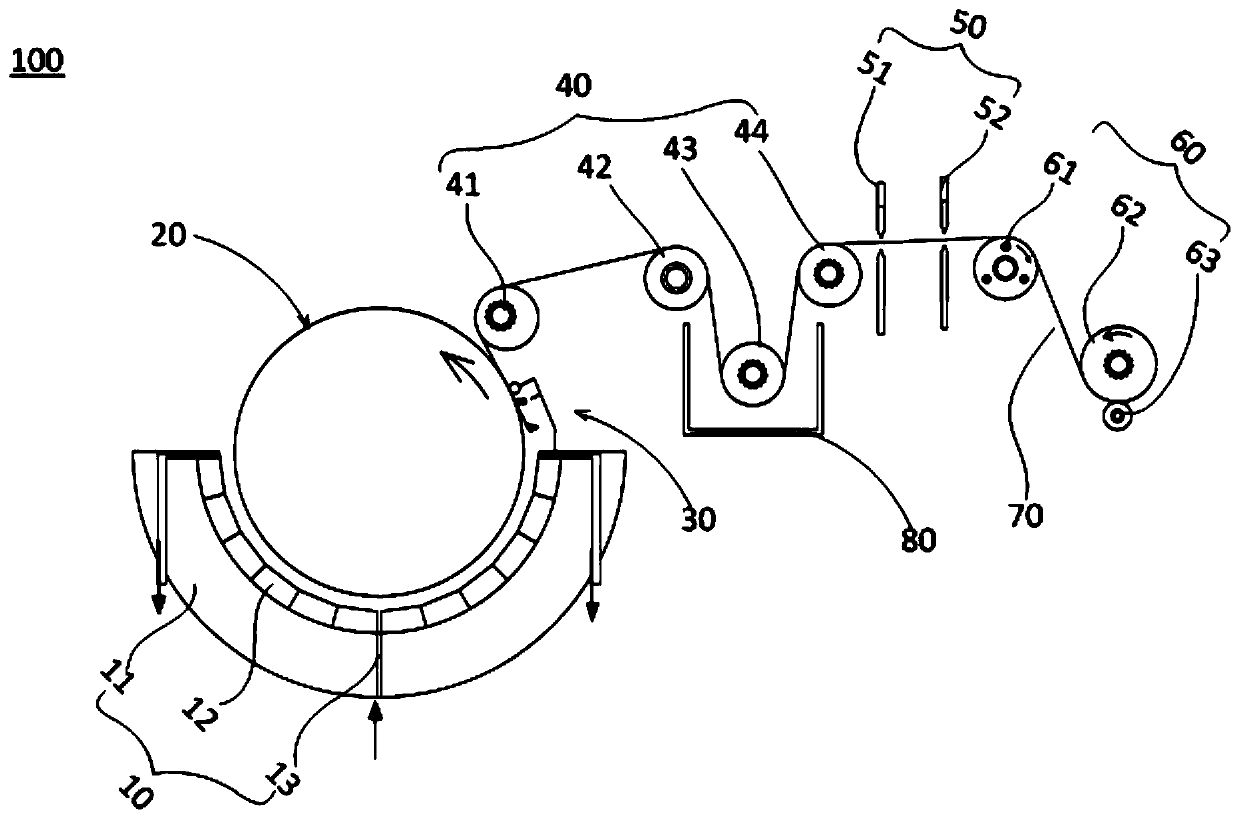

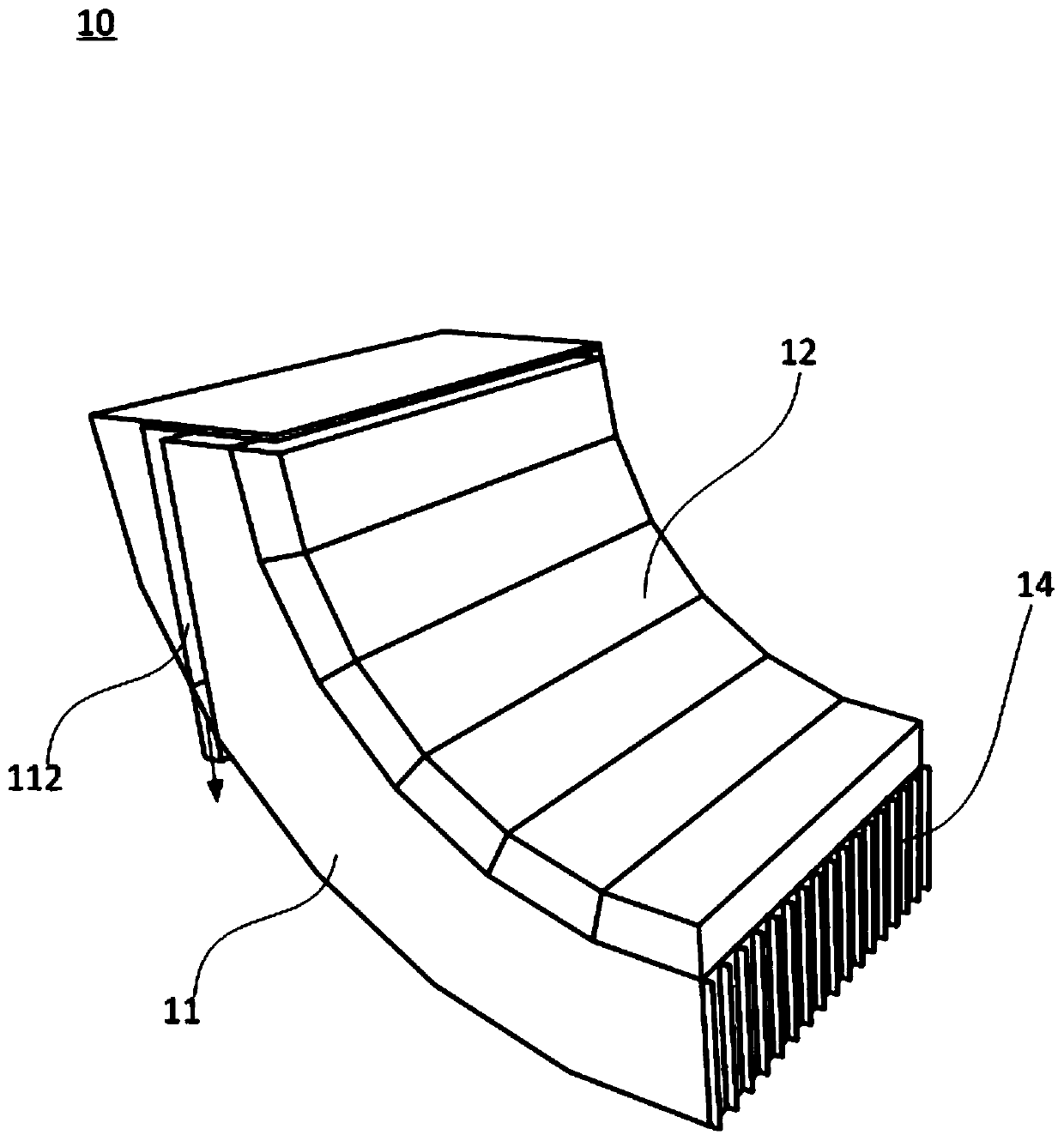

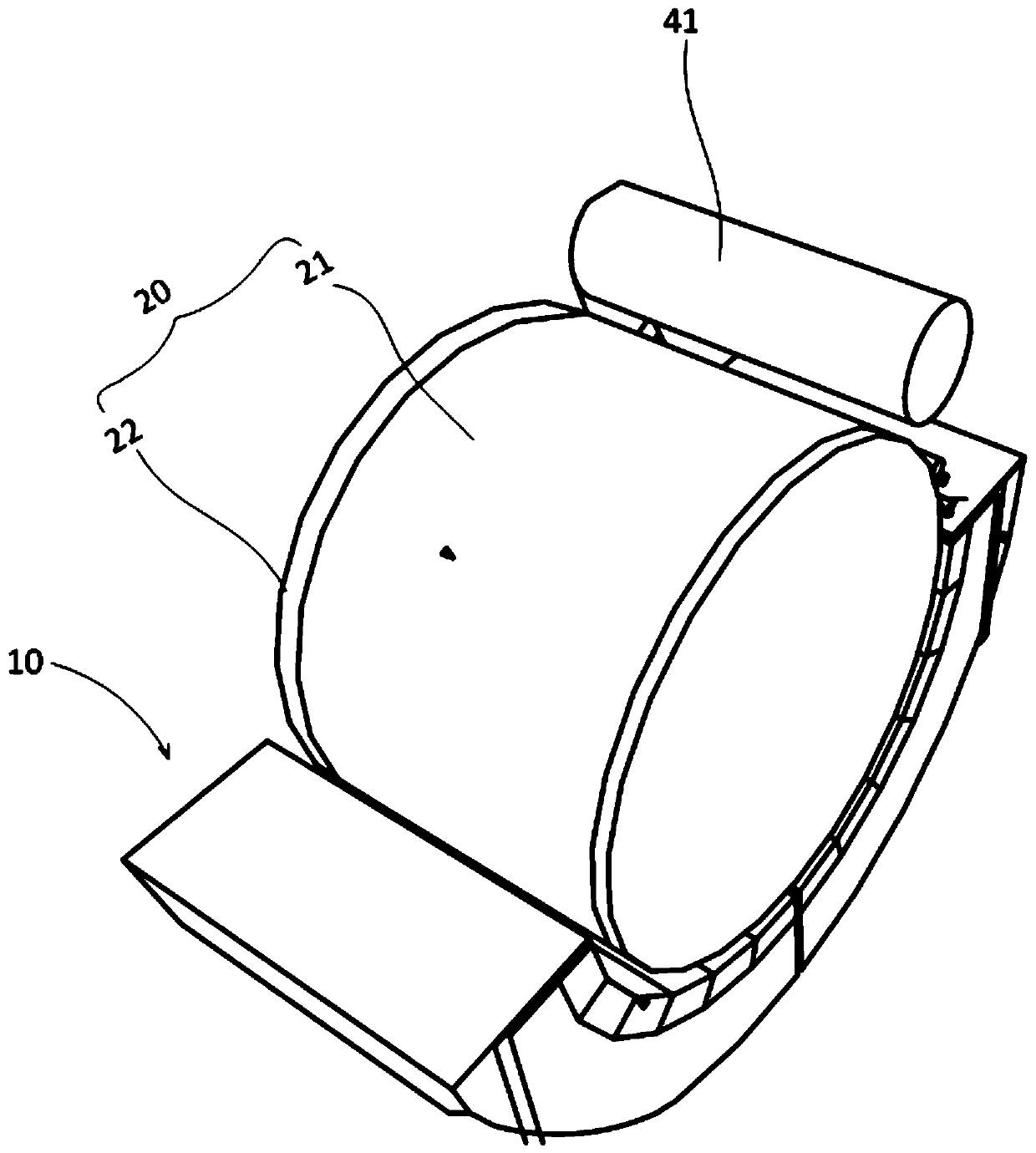

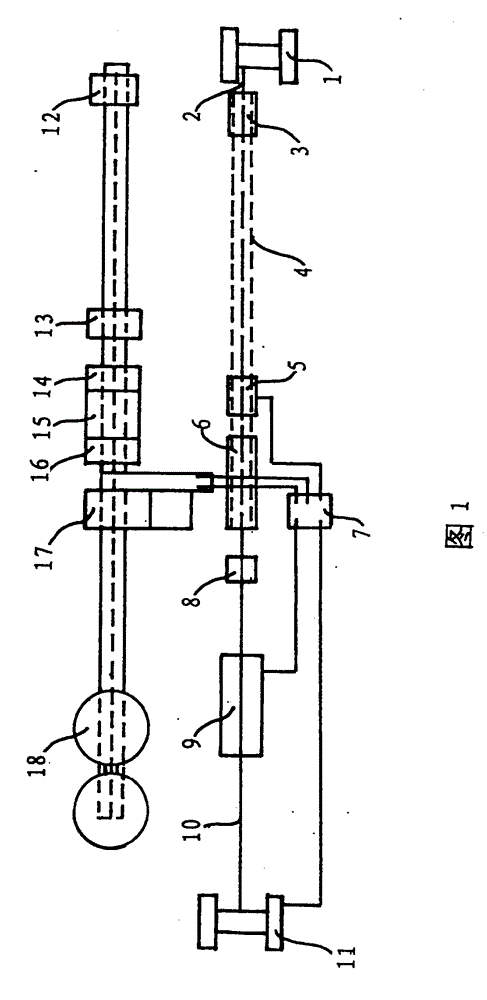

Novel foil producing device for electrolytic copper foil and preparation method of cathode roller

ActiveCN110055560AEliminate pinholesEasily brokenMetallic material coating processesElectroforming processesElectricityElectrolysis

The invention provides a novel foil producing device for an electrolytic copper foil. The novel foil producing device for the electrolytic copper foil comprises a foil producing machine anode unit (10) which is electrically connected with a positive electrode and a cathode roller (20) which is electrically connected with a negative electrode, wherein the cathode roller (20) comprises a roller surface (21) which is used for producing the foil and edge portions (22) which are arranged on the two sides of the roller surface (21), the surface roughness of the roller surface (21) meets the following requirements that Ra is less that 0.2 mm, Rz is less than 1.5 mm, and the edge portions (22) are formed by performing oxidation treatment through hydrogen peroxide.

Owner:FUJIAN QINGJING COPPER FOIL

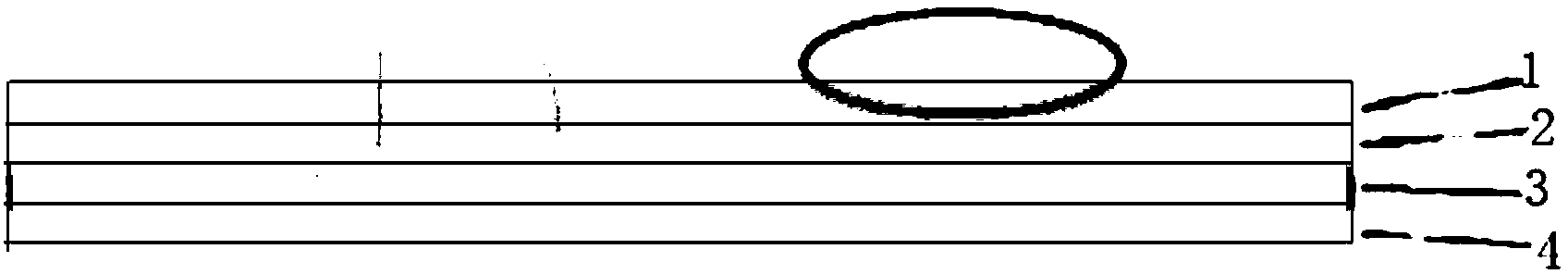

Production method of multi-layer composite adhesive fabric

ActiveCN103360982AGuaranteed compactnessImprove the protective effectNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementChemistry

The invention relates to a production process of an adhesive fabric, particularly relates to a production method of a multi-layer composite adhesive fabric, and solves the technical problem that the adhesive fabric is loose and coarse in surface and extremely poor in protection property due to the fact that bubble, pinhole and sponge phenomena often exist on the surface of the adhesive fabric as a result of identical curing points of each adhesive layer in the multi-layer adhesive fabric production process in the prior art. The production method of a multi-layer composite adhesive fabric comprises the following steps: 1, component preparation: preparing components of two adhesives; 2, compounding: respectively compounding the two adhesives; 3, adhesive cement preparation: preparing adhesive cements of the two adhesives; 4, adhesive coating: coating the adhesive cement of a second adhesive on two faces of a nylon fabric, and then coating the adhesive cement of a first adhesive on one face of the nylon fabric; and 5, curing to obtain the multi-layer composite adhesive fabric. According to the formula of the process provided by the invention, the quality of the product is greatly improved; and the product is smooth and beautiful in surface, and has very good protection property against various corrosive substances.

Owner:SHANXI XINHUA CHEM

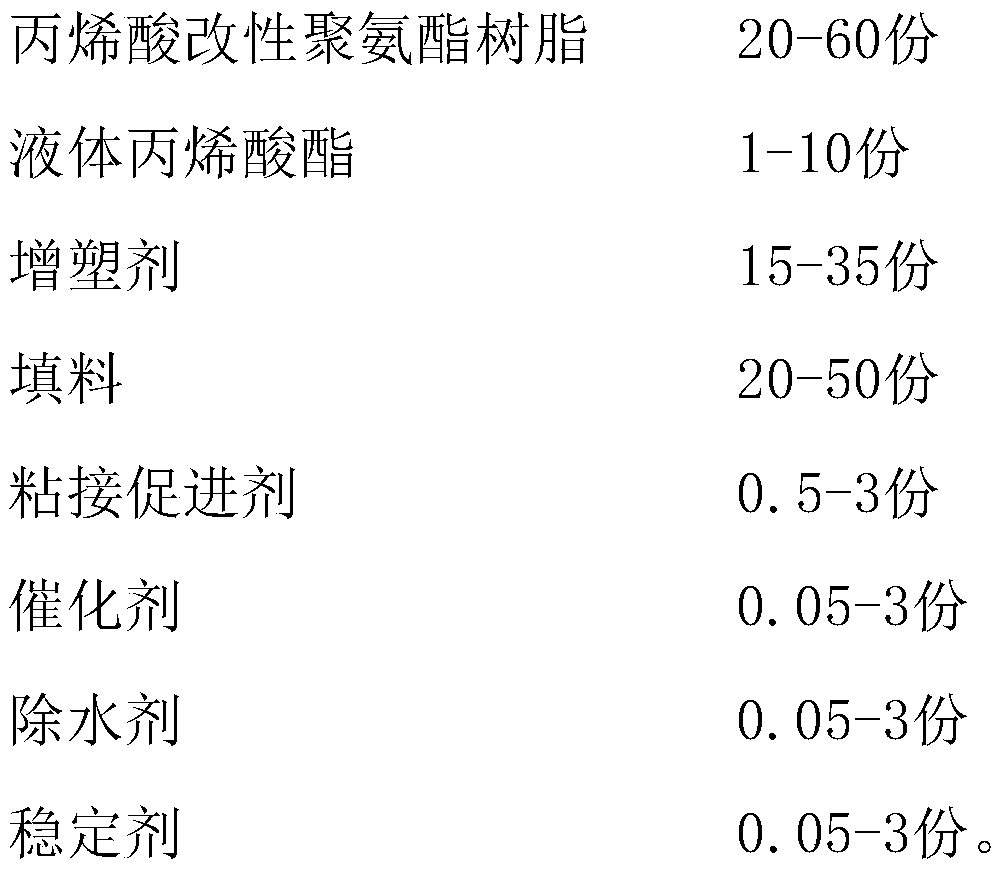

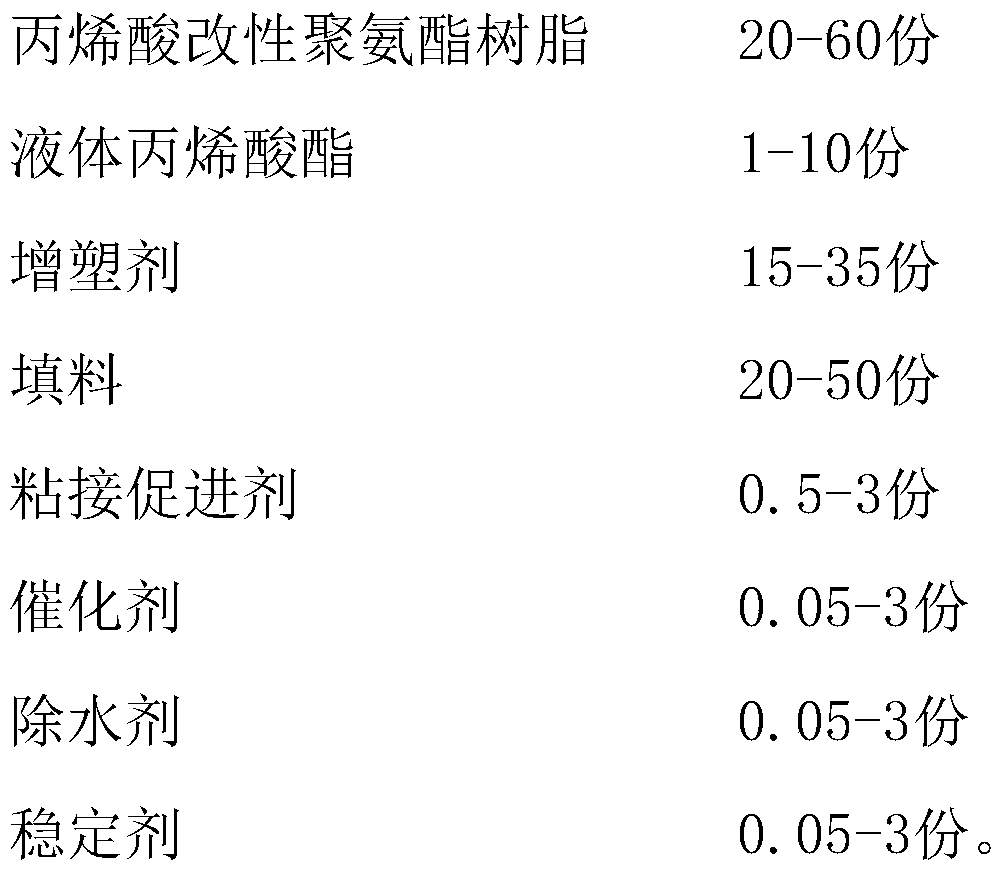

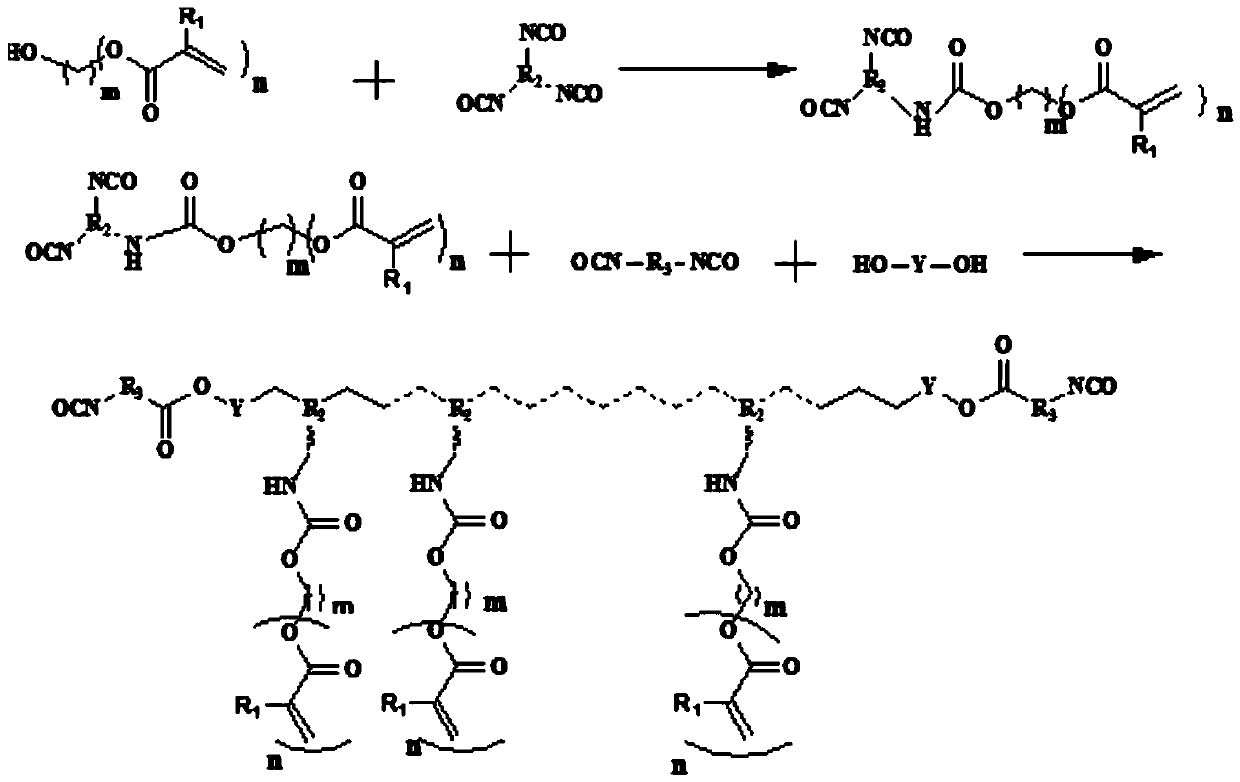

Acrylate modified polyurethane sealant and preparation method thereof

ActiveCN110791251AExtended service lifeGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

The invention relates to the technical field of sealants, more specifically relates to a sealant, in particular to an acrylate modified polyurethane sealant and a preparation method thereof. The acrylate modified polyurethane sealant is prepared from the following raw materials in parts by weight: 20 to 60 parts of acrylic acid modified polyurethane resin, 1 to 10 parts of liquid acrylate, 15 to 35 parts of a plasticizer, 20 to 50 parts of filler, 0.5 to 3 parts of an adhesion promoter, 0.05 to 3 parts of a catalyst, 0.05 to 3 parts of a water removal agent and 0.05 to 3 parts of a stabilizer.According to the invention, the acrylate modified polyurethane resin is adopted; the addition type liquid acrylate resin is matched; the prepared sealant is used in a later natural environment; the energy of ultraviolet irradiation can be transferred to acrylate bonds, so that the acrylate bonds are slowly crosslinked, carbamate bonds in a sealant system are protected, meanwhile, due to crosslinking of acrylate, the weather resistance of the sealant is further improved, the cohesiveness is wide, and the outdoor service life of the polyurethane sealant is prolonged.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Aluminium ware special-purpose noctilucence paint and application

InactiveCN104893492AGood dispersionImprove adhesionLuminescent paintsSpecial surfacesAdditive ingredientLight extinction

The invention discloses an aluminium ware special-purpose noctilucence paint and application, the aluminium ware special-purpose noctilucence paint is characterized by including the following ingredients by weight: 20-80% of resin, 5-60% of a curing agent, 0.1-20% of a levelling agent, 0.01-20% of a gloss enhancer, 1-40% of a pigment, 0.1-10% of a spice, 1-50% of barium sulfate, 0-50% of a light extinction curing agent, and 1-50% of noctilucent powder. Compared with the existing technology, th aluminium ware special-purpose noctilucence paint has low manufacturing cost, strong adhesion, good pigment dispersion and other characteristics, the prepared coating has the characteristics that the surface is smooth, and may not be too bright and blinkering, and is especially suitable for processing of aluminum curtain walls, aluminum doors, aluminum windows and sun room frames.

Owner:何炳贵

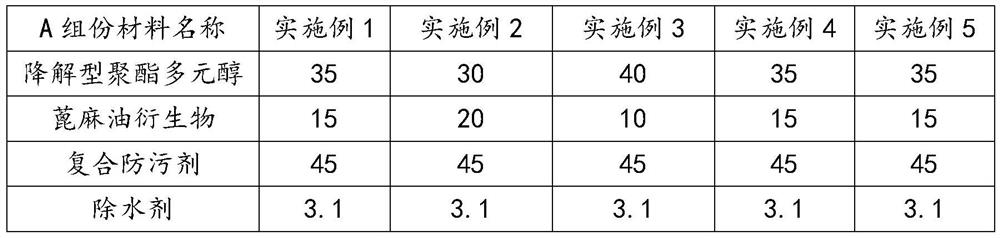

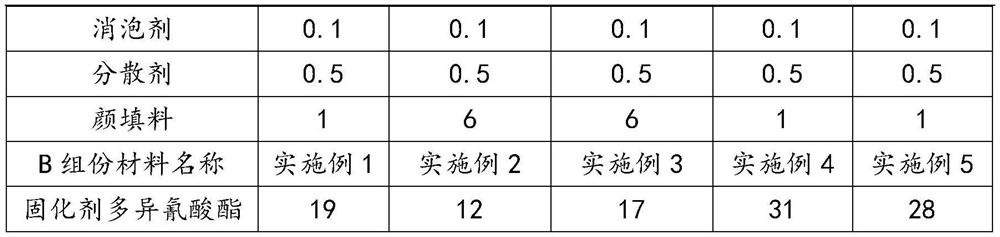

Solvent-free marine antifouling coating and preparation method thereof

InactiveCN112955513AFacilitated releaseNot easy to attachAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to the technical field of coatings, in particular to a solvent-free marine antifouling coating and a preparation method thereof. The coating comprises a component A and a component B. The component A comprises degradable polyester polyol, a castor oil derivative, a composite antifouling agent, a dewatering agent, a defoaming agent, a dispersing agent and pigment filler; and the component B is a curing agent polyisocyanate. According to the solvent-free marine antifouling coating provided by the invention, due to the introduction of isocyanate and the formation of a net structure in the degradable polyester polyurethane resin, a coating film has excellent adhesive force and impact resistance; meanwhile, due to breakage of ester bonds, the paint film can be slowly degraded, the antifouling agent in the coating is released, and the antifouling effect is good. The degradable polyester polyol is combined with the castor oil derivative, so that the crosslinking density and the crosslinking speed of the coating can be adjusted, the mechanical property of the coating is optimized, the reasonable working life of a coating system is obtained, the viscosity of the coating system can be adjusted and controlled, no organic solvent needs to be added, and the environment-friendly characteristic is achieved.

Owner:XIAMEN SUNRUI SHIP COATING

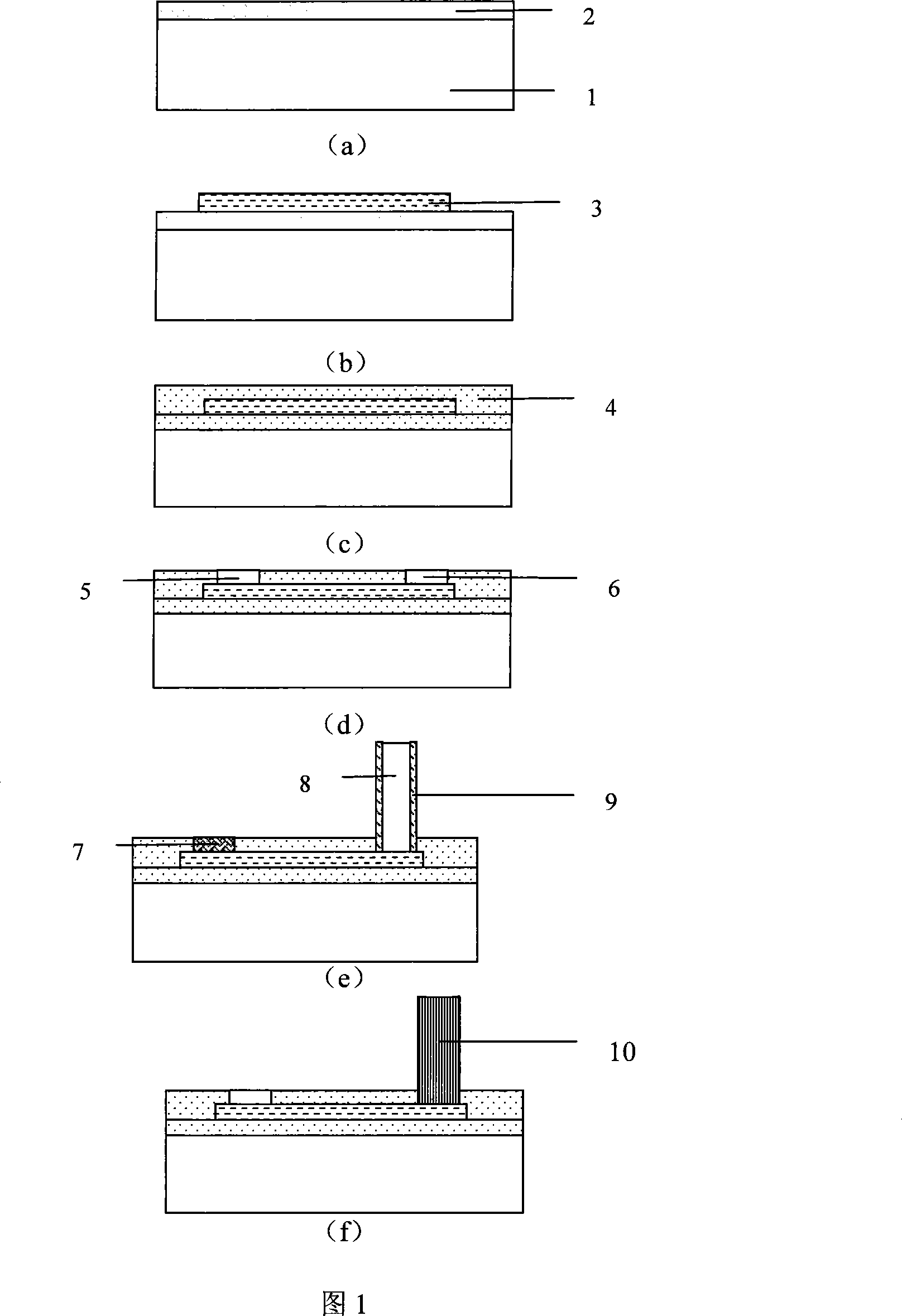

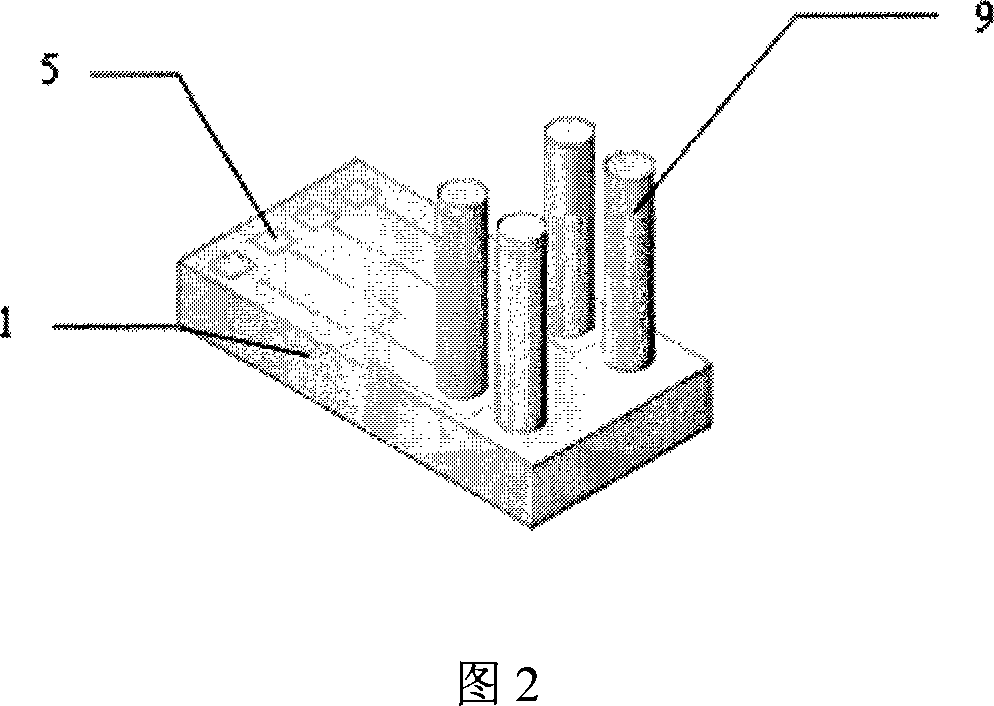

Method for manufacturing three-dimensional nerve microelectrode

ActiveCN101168435AGood consistency of electrical characteristicsElimination of deep etch process stepsDecorative surface effectsChemical vapor deposition coatingResistAdhesive

The invention relates to a process for producing three-dimension nerve microelectrode, belonging to micro mechanical-electric technical field. The invention comprises using silicon chip as substrate, grows a bottom layer SiO2 at the front face of the silicon chip, forming a metal alloy layer on the bottom layer SiO2 and etching metal interconnecting lines, press welding points and contact round points, then growing a top layer SiO2 at the front face of the bottom layer, using buffer HF acid solution to etch the top layer SiO2, to expose the press welding points and the contact round points, and using photo resist to stuff the press welding points, rotationally coating SU-8 adhesive at the front face of the silicon plane structure of the contact round points, via photo-etching and etching techniques to form a cylinder holes, and using photo resist to stuff the press welding points, plating and growing metal in the cylinder holes, to form metal cylinders, uses development to remove the photo resist in the press welding points to expose the press welding points, and finally washing to obtain three-dimension multi-path microelectrode array. The invention can reduce production cost, improve the height controllability of microelectrode, and improve the consistence of each path.

Owner:上海华实投资有限公司

Magnesia porcelain and preparation method thereof

The invention discloses a magnesia porcelain and a preparation method thereof. The magnesia porcelain is prepared by using a billet material and a glaze material, wherein the billet material comprisesthe following components in percentage by weight: 30-45% of burnt talc, 20-35% of raw talc, 5-15% of feldspar, 10-18% of kaolin, 3-5% of bentonite and 0-15% of quartz, and the sum of the weight percentages of the components is 100%; and the glaze material comprises the following components in percentage by weight: 20-40% of feldspar, 5-15% of calcite, 4-8% of kaolin, 0-15% of quartz, 3-5% ZnO, 0-5% of BaCO3 and 20-35% of glass frit, and the sum of the weight percentages of the components is 100%. According to the magnesia porcelain, the quality of the glaze surface is good, the glossiness ishigh, the raw material cost is low, and the production process is simple.

Owner:HUNAN KARPERY INDAL

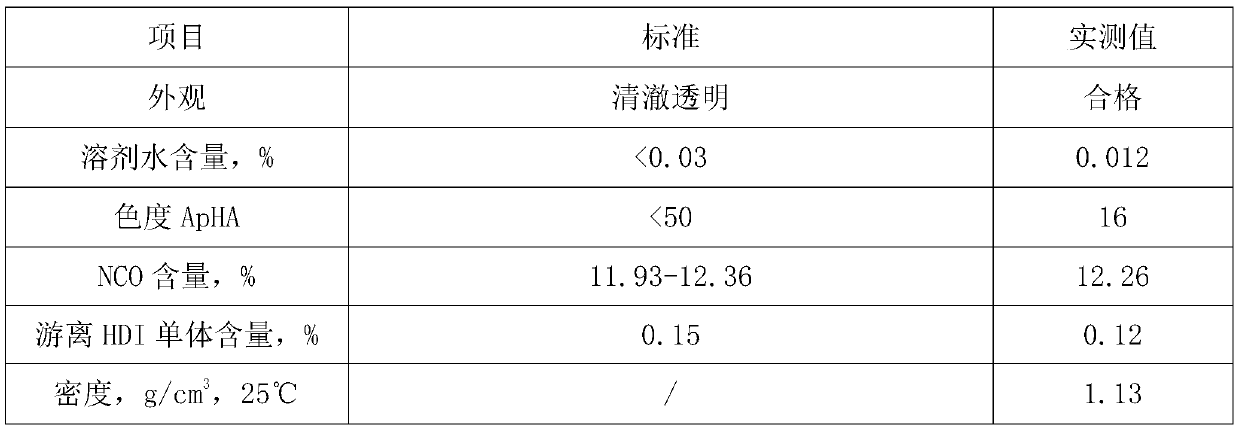

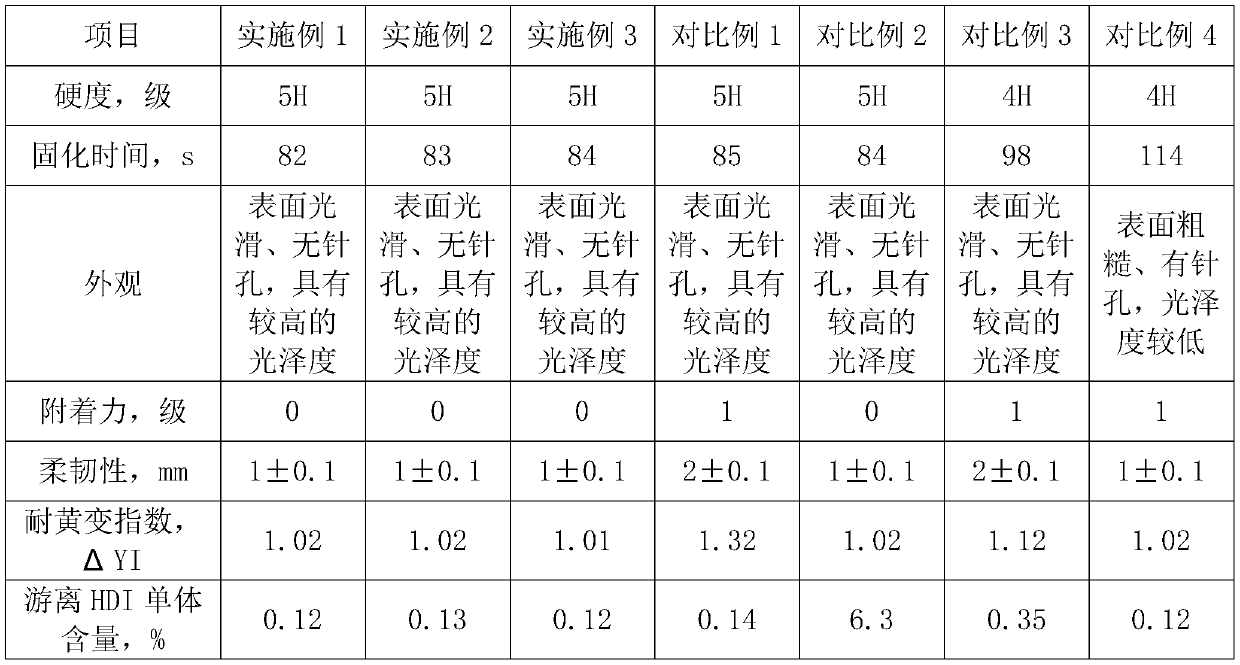

Preparation method of polyurethane curing agent

InactiveCN109824863AImprove stabilityImprove liquidityPolyurea/polyurethane coatingsOrganic solventNitrogen

The invention discloses a preparation method of a polyurethane curing agent and belongs to the technical field of curing agents. The preparation method includes following steps: S1, under protection of nitrogen, enabling oxygen content in a reaction environment to be less than or equal to 1%, and stirring hexamethylenediisocyanate prepolymer, ester solvent, aromatic hydrocarbon organic solvent anddispersant at normal temperature and normal pressure for 20-30min to obtain a mixture; S2, adding a water remover into the mixture, continuing stirring for 5-10min, and using a screen with 100-400 meshes for filtering to obtain the polyurethane curing agent. Through cooperation of the dispersant and the solvent, agglomeration of the hexamethylenediisocyanate prepolymer can be reduced, dispersityof the prepolymer can be improved, and fluidity of the curing agent can be improved.

Owner:SHANGHAI INABATA FINE CHEM CO LTD

High-glossiness reinforced magnesia porcelain and preparation method thereof

The invention discloses a strengthened magnesia porcelain with high gloss and a preparation method thereof. The strengthened magnesia porcelain is composed of the following raw materials according to mass percentage: 60-70% of talc, 10-15% of Chaozhou bentonite, and 8-8% of Longyan kaolin 10%, quartz 2‑6%, potassium feldspar 5‑12%. Grind talc, Chaozhou bentonite, Longyan kaolin, quartz, and potassium feldspar respectively, pass through a 200‑400 mesh sieve, weigh them according to the mass percentage, and then form, dry, and fire to obtain strengthened magnesia porcelain. The firing temperature range is 1250-1300°C, the holding time is 0.5-8h. The invention adopts natural mineral raw materials, and through repeated batching tests, the raw materials in the magnesia green body are well matched, and the strengthened magnesia porcelain products with good glaze quality and high gloss are produced, and the performances of the reinforced magnesia porcelain products reach GB / T3532‑1995 According to the standard requirements, the whiteness of its products is above 86 degrees, and the edge impact strength is 0.693J / cm 2 . Thermal shock resistance: 180‑20°C without cracking once. It effectively eliminates the pinholes in the glaze and improves the brightness of the glaze, so it has a broad market prospect.

Owner:DEHUA HENGHAN ARTS

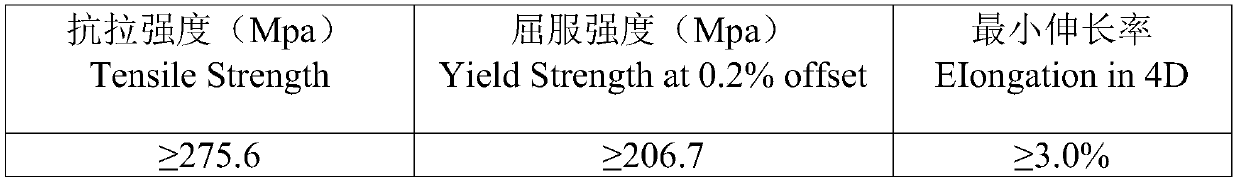

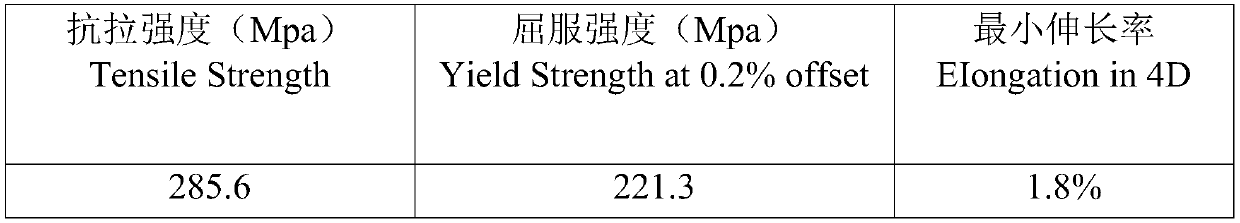

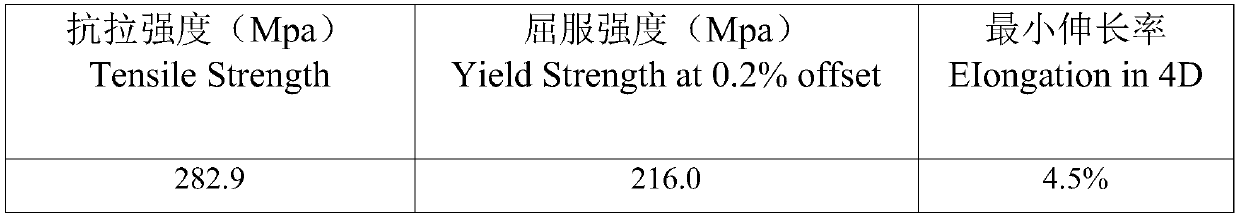

Process method capable of improving mechanical property of aluminum alloy

The invention provides a process method capable of improving the mechanical property of aluminum alloy. The process method capable of improving the mechanical property of the aluminum alloy comprisesthe following steps: (1) smelting: heating an A356 aluminum alloy ingot to 730 to 750 DEG C to melt, and adding a modifier to treat an alloy melt; (2) casting: performing gas-removing refining, standing and drossing treatment on the A356 aluminum alloy melt obtained in the step (1), and then casting to product a product; (3) performing hot isostatic pressing: performing hot isostatic pressing on the product obtained in the step (2); (4) performing solid solution treatment: performing solid solution treatment on the product obtained in the step (3); (5) performing aging treatment: performing aging treatment on the product obtained in the step (4); (6) air-cooling: air-cooling the product aged in the step (5) after discharging; and (7) detecting: detecting the mechanical property of the product obtained in the step (6). After the modifier is added, the spheroidizing speed of silicon during aluminum alloy heat treatment can be increased, the coarsening speed of the silicon during heat treatment can be reduced, and the yield strength and the extending rate of the aluminum silicon alloy can be significantly improved.

Owner:鹰普航空科技有限公司

Corrosion-resistant environment-friendly glaze for tiles

InactiveCN108609850AStrong acid and alkali corrosion resistanceExtended service lifeHigh resistancePyrophyllite

The invention mainly relates to the technical field of ceramic glaze processing and discloses corrosion-resistant environment-friendly glaze for tiles. The glaze is prepared from, by weight, 37-39 parts of silicon dioxide, 26-28 parts of barite, 24-26 parts of barium feldspar, 17-19 parts of pyrophyllite, 14-16 parts of kaolinite, 5.2-5.6 parts of tin oxide, 4.5-4.9 parts of niobium pentoxide, 4.1-4.5 parts of tungsten oxide, 3.4-3.8 parts of cerium oxide, 2.3-2.7 parts of cobalt oxide and 0.3-0.5 part of graphene. The glaze can eliminate pinholes and bubbles, thereby avoiding glaze shrinkage,enabling the surfaces of the tiles to be exquisite and bright and having high resistance to acid and alkali corrosion, and after glazing, sintering is low in temperature and short in time, energy issaved, and environment is protected; cobalt oxide is added for calcining modification after pyrophyllite is smashed, so that hardness and glossiness of pyrophyllite powder are improved, the surfaces of the tiles are made smooth and exquisite, and corrosion resistance is enhanced.

Owner:合肥汉甲陶瓷科技有限公司

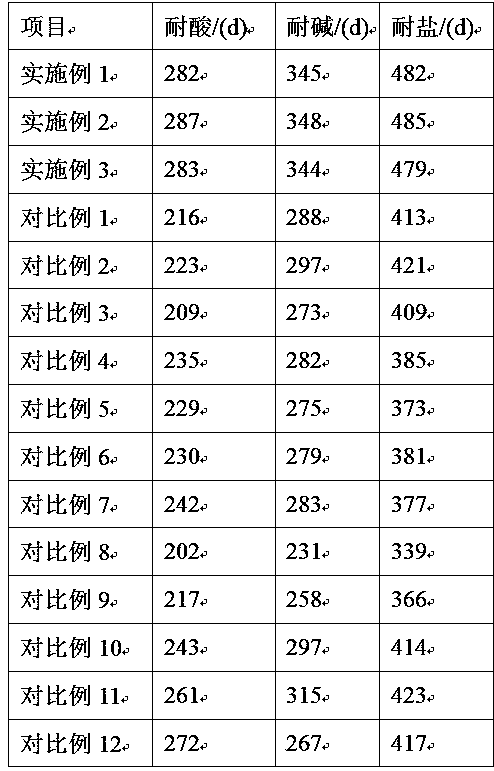

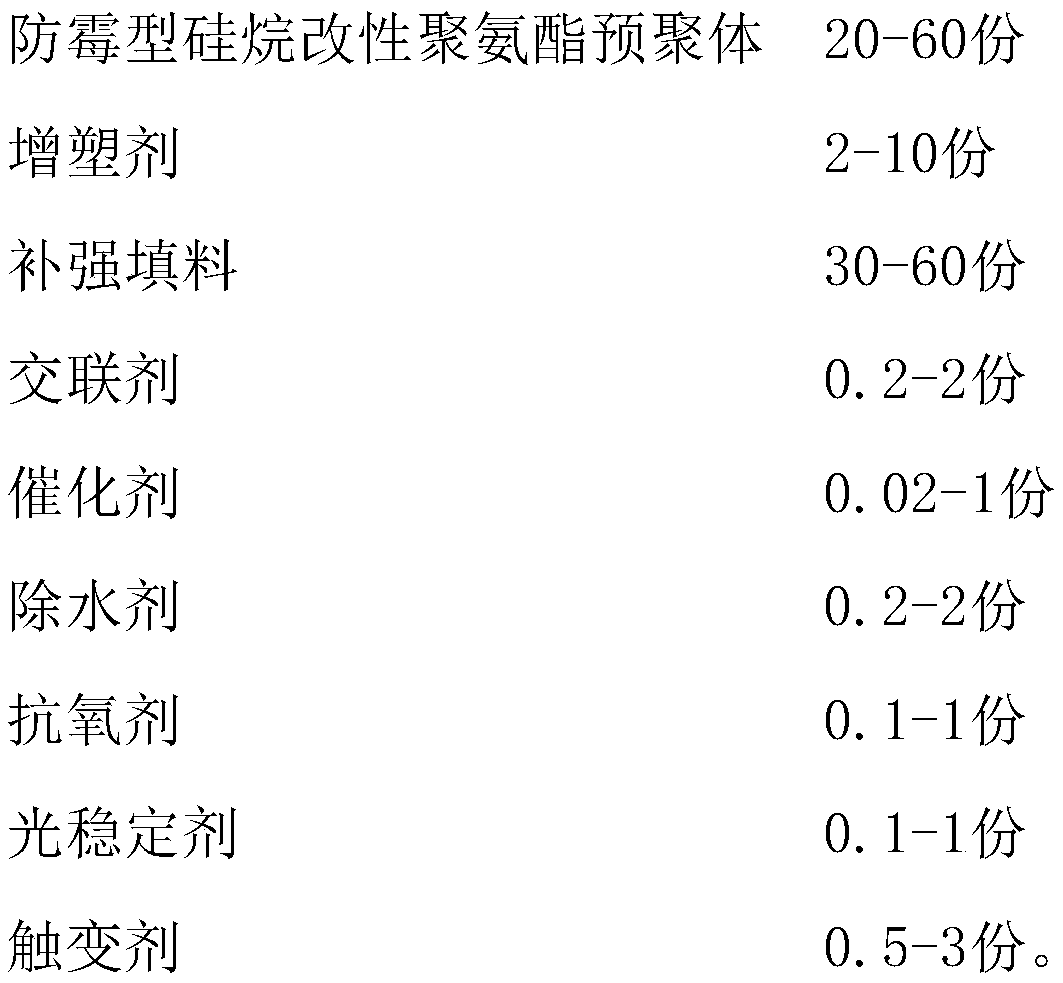

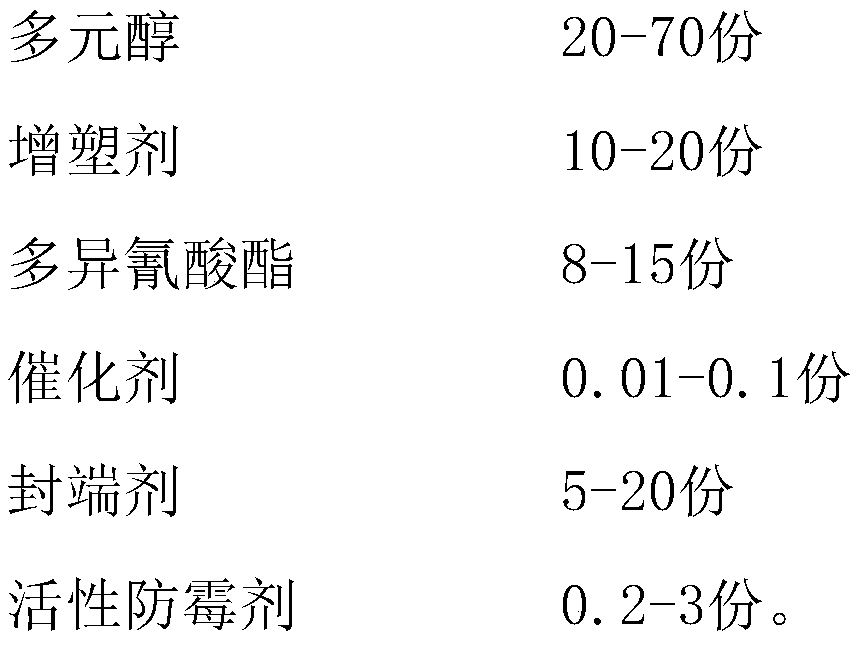

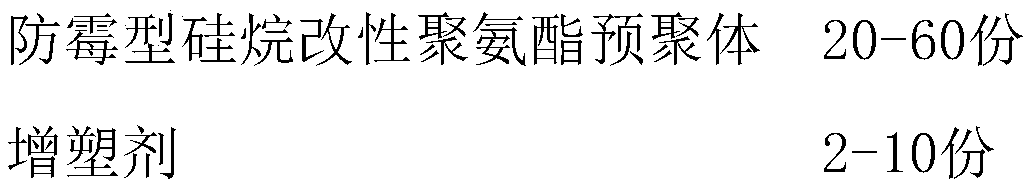

Mildew-proof silane modified polyurethane sealant and preparation method thereof

InactiveCN110655898AGood adhesionNot easy to yellowNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerPolymer chemistry

The invention relates to the technical field of sealants, and concretely relates to a mildew-proof silane modified polyurethane sealant and a preparation method thereof. The sealant comprises, by weight, 20-60 parts of a mildew-proof silane modified polyurethane prepolymer, 2-10 parts of a plasticizer, 30-60 parts of a reinforcing filler, 0.2-2 parts of a crosslinking agent, 0.02-1 part of a catalyst, 0.2-2 parts of a water removal agent, 0.1-1 part of an antioxidant, 0.1-1 part of a light stabilizer and 0.5-3 parts of a thixotropic agent. The mildew-proof silane modified polyurethane sealanthas excellent cohesiveness, and is not prone to yellowing; the sealant is prepared by adopting a mildew-proof silane modified polyurethane prepolymer, so that the prepared silane modified polyurethanesealant has a stable and lasting mildew-proof effect, is not prone to yellowing, and is suitable for kitchen and bath decoration; and the preparation method of the polyurethane sealant has the advantages of simplicity in operation, convenience in control, low production cost and high product quality, and is used for large-scale production.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

Thermosetting powder coating additive and preparation process thereof

The invention discloses a thermosetting powder coating additive and a preparation process thereof, belongs to the technical field of coatings, and aims to provide an additive with functions of promoting wetness to eliminate shrinkage cavities of a coating film so as to obtain the smooth, bright and plump coating film, and eliminating pinholes caused by by-products with low boiling points or water absorbed in pigment fillers during the coating curing so as to improve the toughness of the coating film and enhance the hardness of the surface of the coating film. The additive is generally suitable for thermosetting powder coatings (a plane high-gloss type, a semigloss type or a non-gloss type). In addition, the invention further discloses a preparation process of the thermosetting powder coating additive.

Owner:玉石塑粉有限公司

Aid-containing thermosetting powder coating

The invention discloses an aid-containing thermosetting powder coating which comprises the following raw materials: resin, a curing agent, a pigment, fillers and aids, wherein the content of the aids is 4%, and the total content of the resin, the curing agent, the pigment, the fillers and the aids is 96%; the aids comprise a first premixture and a second premixture; the first premixture comprises a liquid leveling agent and fumed silica; the second premixture comprises benzoin, a 701 wetting agent, hydrogenated castor oil, ethylene bis stearamide, polytetrafluoroethylene wax and butyral.

Owner:华威控股集团有限公司

Low-separation bonding shining silver powder coating and preparation method thereof

InactiveCN107337986AExtended service lifeImprove responsePowdery paintsEpoxy resin coatingsEpoxyGlass transition

The invention discloses a low-separation bonding shining silver powder coating. The low-separation bonding shining silver powder coating is prepared from, by weight, 25-35 parts of epoxy resin, 25-35 parts of carboxyl-terminated polyester resin, 10-15 parts of hydroxyl polyester resin, 1-3 parts of polyacrylate, 0.3-0.5 part of benzoin, 1-1.5 parts of silane coupling agent, 10-15 parts of barium sulfate, 5-10 parts of light calcium carbonate, 0-3 parts of titanium dioxide, 1-6 parts of surface-coated aluminum powder and 1-2 parts of bonding additive. The invention further provides a preparation method of the low-separation bonding shining silver powder coating. Through ingredient weighing, premixing, melting extrusion, grinding, screening, bonding, screening and finished product packaging, the low-separation bonding shining silver powder coating is obtained; through adjustment of the melting viscosity, glass transition temperature, bonding temperature and bonding time of the powder, the powder fully bonds with particles of the aluminum powder, so that the bonding rate reaches 98-100%, the separation rate of the aluminum powder is reduced, and the service life of coating film is prolonged.

Owner:浙江绿能塑粉科技股份有限公司

High-imitation electroplating bonding silver powder paint and preparation method thereof

InactiveCN107216778AAdjust levelingImprove responsePowdery paintsPolyester coatingsWhitening AgentsGlass transition

The invention discloses high-imitation electroplating bonding silver powder paint which comprises the following components in parts by weight: 80-90 parts of terminal carboxyl group polyester resin, 6-8 parts of isocyanate triglycidyl ester, 10-15 parts of organic silicon resin, 5-10 pars of terpene resin, 1-3 parts of polyacrylate, 0.3-0.7 part of benzoin, 0.5-1 part of a fluorescent whitening agent, 1-2 parts of a bonding aid and 0.6-1 part of coating type aluminum powder. The invention further provides a preparation method of the high-imitation electroplating bonding silver powder paint. The preparation method comprises the following steps: weighing and blending materials, premixing the materials, performing melting extrusion, grinding, bonding, screening, and packaging a finished product, thereby obtaining the high-imitation electroplating bonding silver powder paint. By adopting the high-imitation electroplating bonding silver powder paint and the preparation method thereof, effects of high smoothness, high clarity, high brightness and high leveling properties of an electroplated surface are achieved by adjusting the melting viscosity, clarity, surface tension, glass transition temperature, bonding temperature, bonding time, bonding speed and powder flowability of a formula.

Owner:浙江绿能塑粉科技股份有限公司

High-temperature high-grade magnesia porcelain preparation method

The invention relates to a high-temperature high-grade magnesia porcelain preparation method, wherein the billet material comprises, by weight, 30-45% of burned talc, 20-35% of raw talc, 5-15% of feldspar, 10-18% of kaolin, 3-5% of bentonite, and 0-15% of quartz, and the glaze material comprises, by weight, 20-40% of feldspar, 5-15% of calcite, 4-8% of kaolin, 0-15% of quartz, 3-5% of ZnO, 0-5% ofBaCO3, and 20-35% of frit. According to the preparation method, billet material and glaze material preparation, molding, drying, biscuit firing of billet body, glazing, drying, and medium temperatureglaze burning to obtain the product, wherein the biscuit firing temperature is 1280-1300 DEGC, the thermal insulation is 30 min, the medium temperature glaze burning temperature is 1200 DEGC, and thethermal insulation is 30 min. According to the present invention, with the preparation method, the product with advantages of good glaze surface quality and high glossiness is obtained so as to achieve broad application prospects.

Owner:叶剑

Anti-drag wear-resistant solvent-free coating with low-viscosity for pipeline

ActiveCN102417780BStrong adhesionGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to the technical field of coatings, in particular to an anti-drag wear-resistant solvent-free coating with low-viscosity for a pipeline. The anti-drag wear-resistant solvent-free coating with the low-viscosity comprises a component A and a component B, wherein the component A comprises epoxy resin, an active diluent, a flatting agent, an antifoaming agent, a dispersant, a thixotropic agent 1, a thixotropic agent 2, zinc phosphate, silica, iron oxide red powder, aluminum triphosphate and white pottery powder; the component B comprises modified amine and a thixotropic synergistic agent; and the component A and the component B are used together in the mass ratio of (3-5):1. The solvent-free coating with the low-viscosity has the positive effects of freeness from volatilizable solvent, capability of eliminating coating pin holes, high adhesion, high permeation resistance, high wear resistance, high corrosion resistance, smooth coating surface after being sprayed, good anti-drag and wear-resisting effects, and popularization and application prospects.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

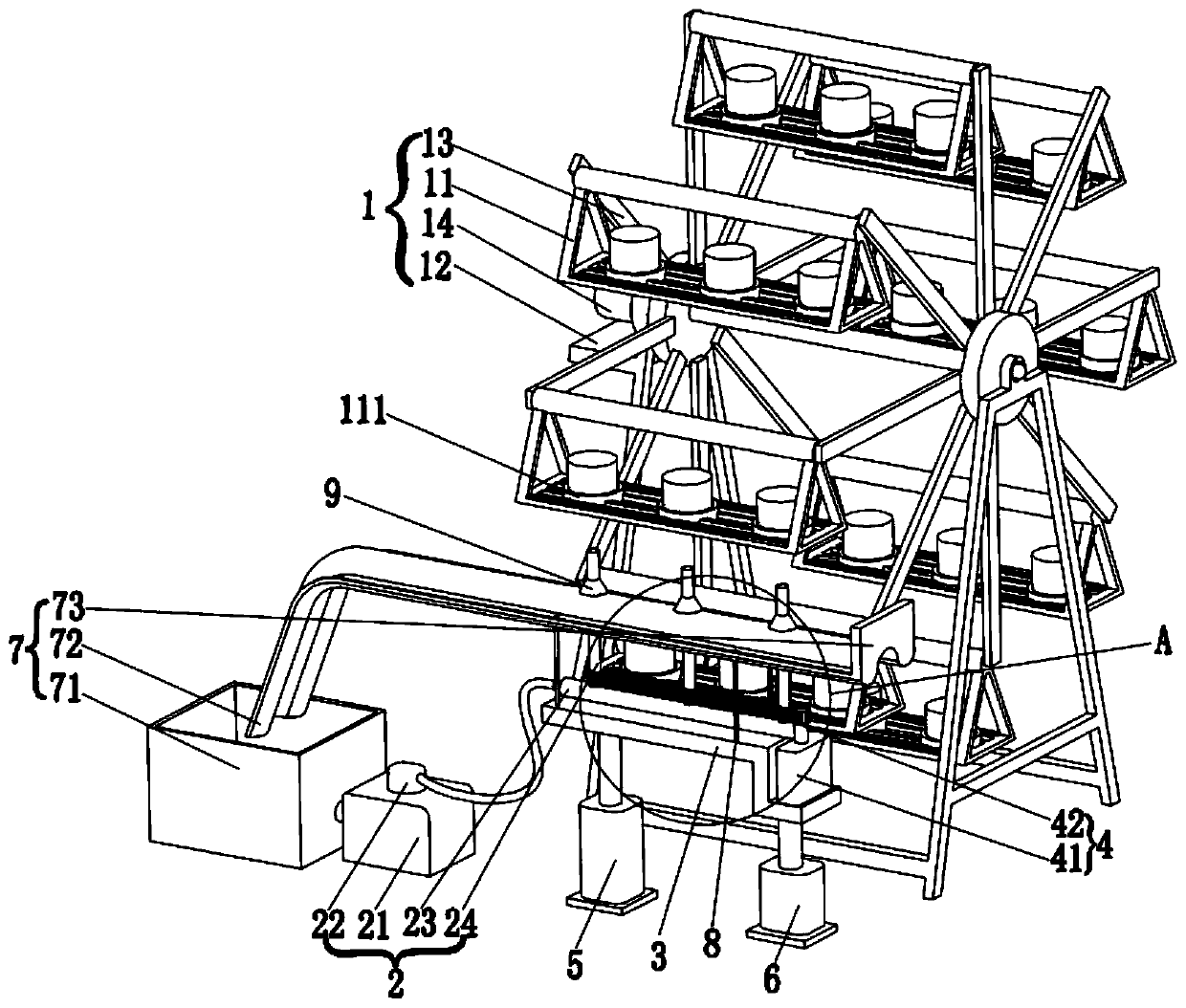

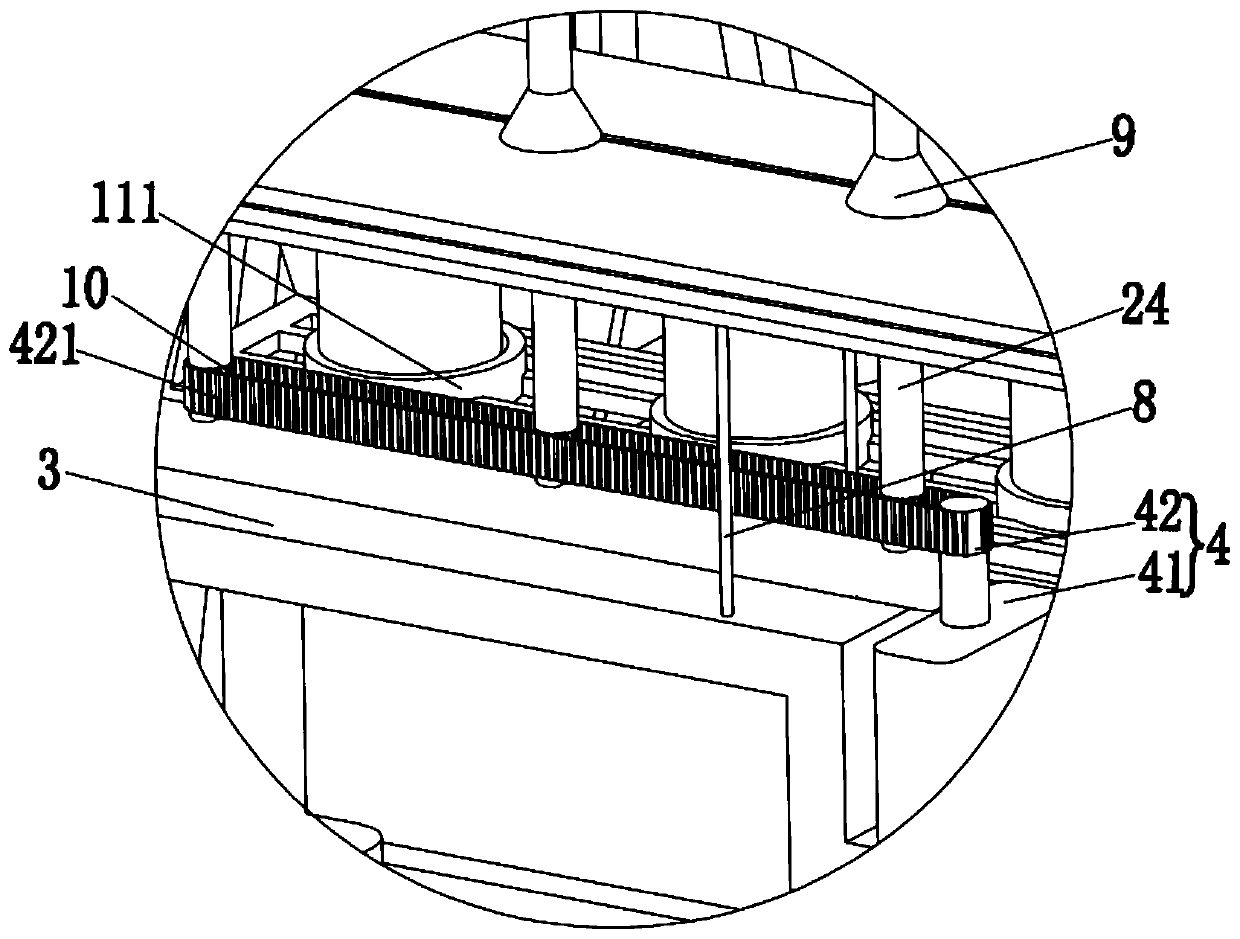

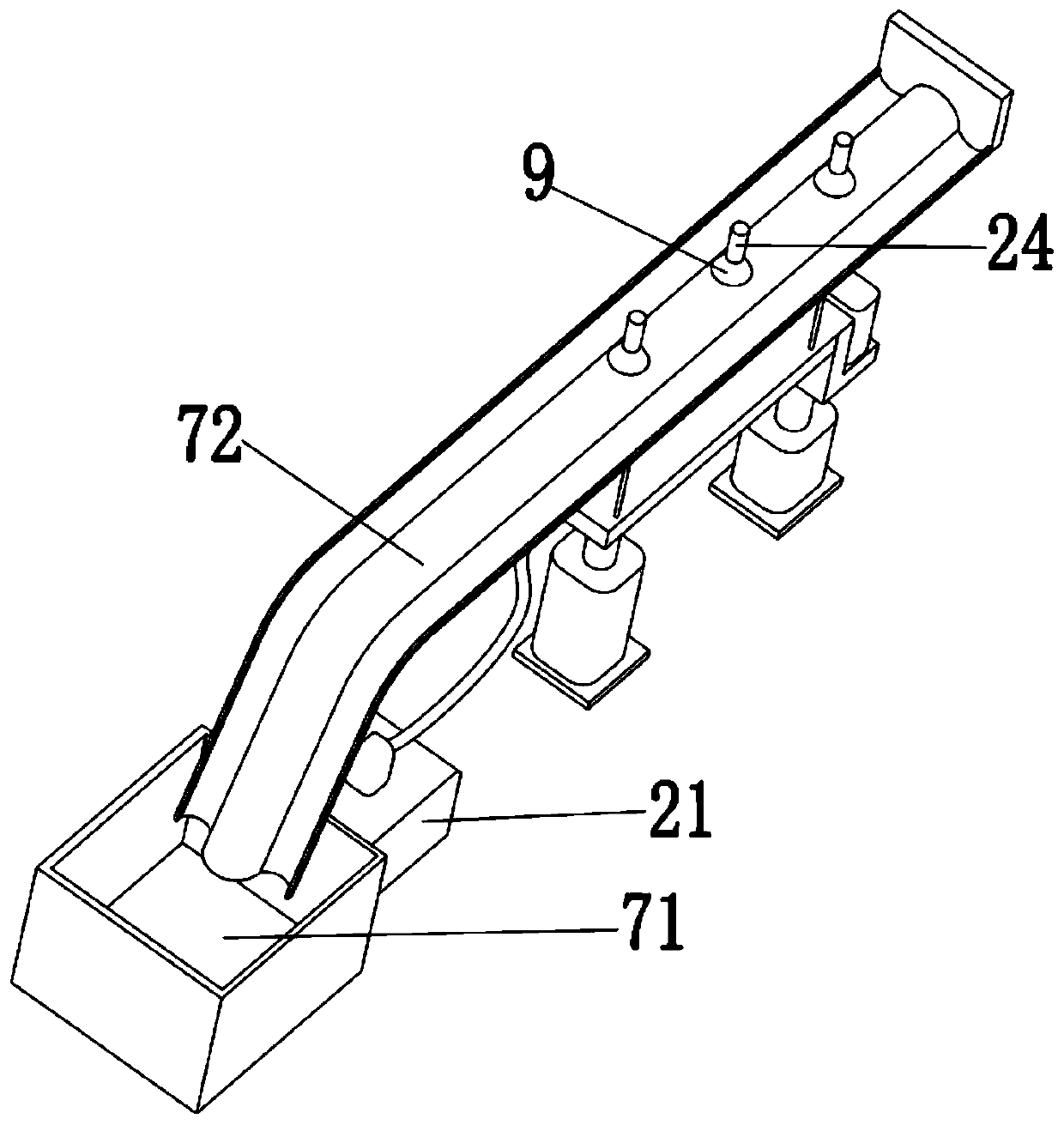

Ceramic slushing forming device

PendingCN110027087AAchieve Rotary JettingAchieve recyclingFeeding arrangmentsAuxillary shaping apparatusWater wheelAutomatic control

The invention discloses a ceramic slushing forming device. The ceramic slushing forming device comprises a rotating device with a water wheel type and a slushing device, wherein a plurality of mold frames for placing molds are arranged on the rotating device, and the mold frames are distributed in the circumferential direction of the rotating device; the slushing device comprises a slurry storagetank, a stamping pump, a slurry conveying pipe, a communicating pipe and a plurality of spray heads, wherein one end of the slurry conveying pipe is connected with the stamping pump, the other end ofthe slurry conveying pipe is connected with the communicating pipe, and the spray heads are rotatably connected with the communicating pipe; and the low end of the communicating pipe is fixedly connected with a fixed seat, the fixed seat is further provided with a transmission device, a first push-pull device and a second push-pull device are arranged at the lower end of the fixed seat, and the fixed seat moves up and down through the first push-pull device and the second push-pull device. The ceramic slushing forming device is suitable for processing ceramic products with various shapes, a formed blank has uniform thickness, pinholes of the blank can be eliminated, automatic control is adopted, the cost is reduced, and the efficiency is improved.

Owner:福建省德化县豪鹏机械有限公司

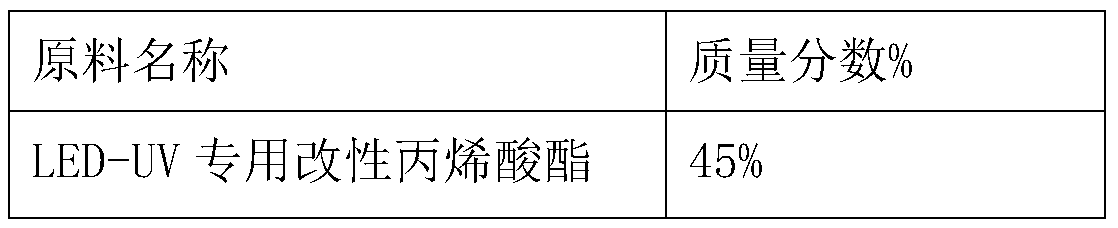

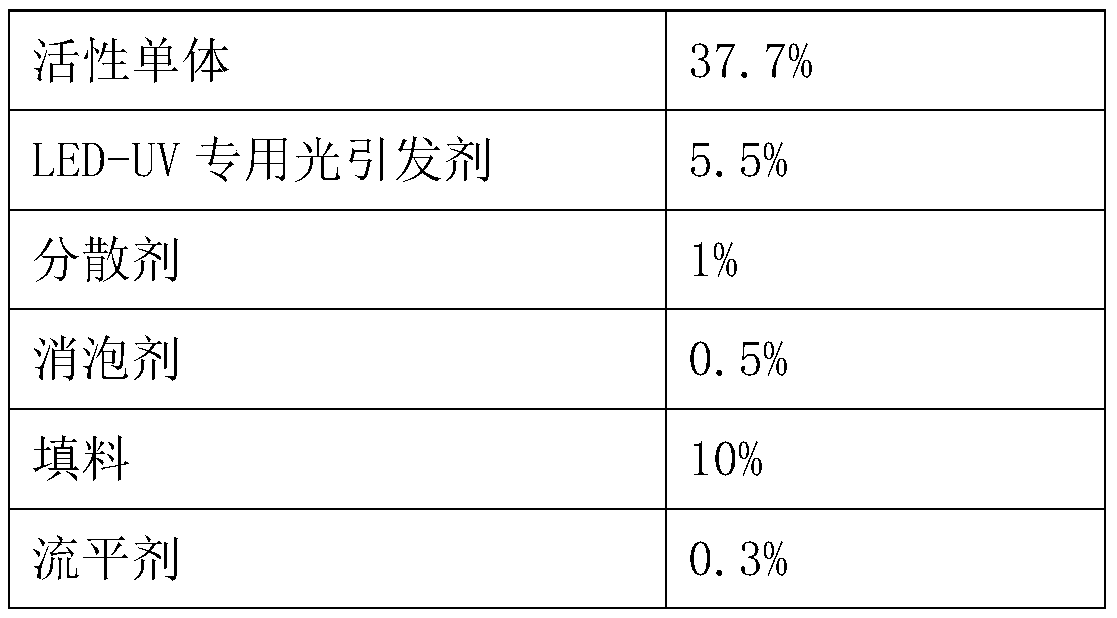

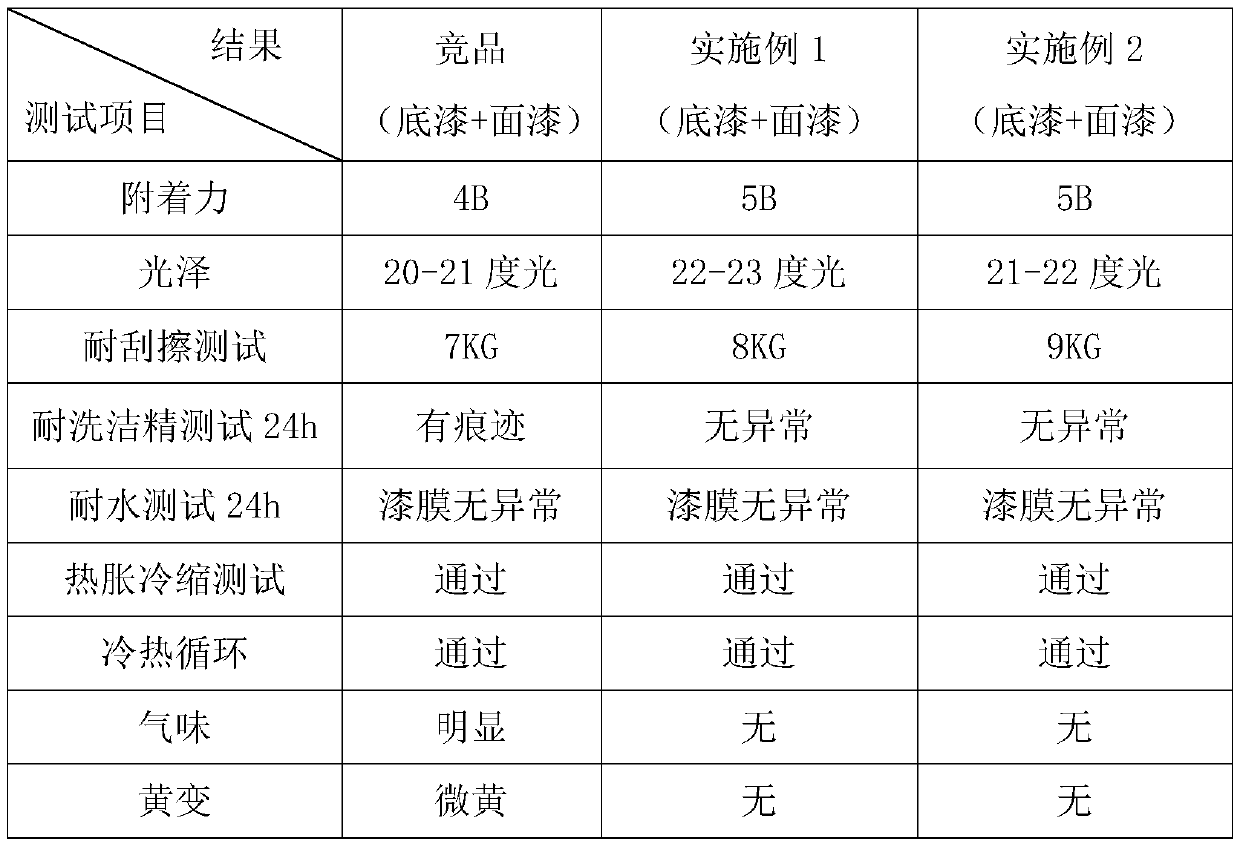

LED-UV light curing solventless varnish

InactiveCN109852115AEliminate Coating PinholesImprove corrosion resistanceAnti-corrosive paintsSolventChemistry

The invention discloses a LED-UV light curing solventless varnish. The varnish comprises a primer and a topcoat which are cooperatively used; wherein the primer is prepared by the following componentsin mass percent: 40-50% of modified acrylate special for LED-UV, 30-40% of an active monomer, 5-6%of a photo initiator special for LED-UV, 0-1% of a dispersant, 0-1% of an anti-foaming agent, 10-15%of a filler, and 0-1% of a leveling agent; and the topcoat is prepared by the following components in mass percent: 40-55% of modified acrylate special for LED-UV, 35-45% of an active monomer, 4-6% ofa photo initiator special for LED-UV, 0-1% of a dispersant, 0-1% of an anti-foaming agent, 5-10% of delustering powder, and 0-1% of a leveling agent. The prepared varnish products can break through the problem of oxygen inhibitory polymerization, pinholes in the coating can be eliminated, the corrosion resistance is improved, and the paint film surface layer curing, taste cleaning, clearing and no yellowing are achieved, so that the varnish has excellent physical and chemical properties.

Owner:上海君子兰新材料股份有限公司

Water-based polyurethane anticorrosive coating for containers and preparation method for coating

ActiveCN102618159BNo pollutionPollution meetsAntifouling/underwater paintsPaints with biocidesWater basedRust

The invention discloses a water-based polyurethane anti-corrosion coating for containers and a preparation method thereof. The raw material formula is composed of the following components in terms of weight percentage: 5-14% of tap water, 20-50% of water-based polyurethane dispersion, and 10% of acrylic emulsion -20%, anti-rust pigment 5-10%, body filler 10-25%, coloring pigment 0-15%, anti-settling agent 0.3-1.0%, film-forming aid 2-6%, thickener 0.3-1.0% , defoaming agent 0.1-0.4%, salt-spray resistant hydrophobic agent 0.5-1.0%, anti-corrosion and anti-mold agent 0.1-0.3%, pH regulator 0.1-0.4%, wetting and dispersing agent 0.5-1.0%, antifreeze agent 0.5-2 %, leveling agent or substrate wetting agent 0.1-0.4%; the product of the present invention does not contain harmful substances such as organic solvents and heavy metals, and has excellent environmental protection, simple and convenient construction, safe and stable storage, and excellent performance.

Owner:GUANGZHOU JOINTAS CHEM

Production process of aluminum sheath cable

ActiveCN101685690BEliminate pinholesAvoid scrap rateCable/conductor manufactureHigh energyEngineering

The invention discloses a production process of an aluminum sheath cable, relating to the field of communication and signal cable production. The traditional high-frequency welding process is difficult to avoid the problems of pin holes and tack weld, and the standard length of each weldment is only 6 m; in order to weld an aluminum sheath cable, the length of which can reach thousand meters, the invention provides the production process for welding the aluminum sheath cable by the following steps: firstly shaping by a sheath and then welding at high frequency, wherein the thickness of an aluminum tape is 0.5-2.5 mm, the diameter of the aluminum sheath is 10-70 mm, the welding depth is 0.3-2.0 mm, the welding meeting angle is 4-12 degrees, the frequency of induced current is 350-500kHz, the welding power is 100-200kW and the welding speed can approach 100m / min; heating the aluminum sheath cable to be in a molten state at the edge of the meeting angle; then combining contact surface molecules by the extrusion of both side extruding devices to form crystal so as to achieve the goals of no pin holes, no tack weld and even welding; and finally reducing and shaping. The invention has the advantages of simple process, reliable quality, low cost, high production efficiency and little energy consumption.

Owner:TIANSHUI RAILWAY CABLE

Low-temperature high-grade magnesia porcelain preparation method

The invention relates to a low-temperature high-grade magnesia porcelain preparation method, wherein the billet material comprises, by weight, 32% of burned talc, 26% of raw talc, 10% of feldspar, 15%of kaolin, 4% of bentonite, 10% of quartz, and 3% of calcium carbonate, and the glaze material comprises, by weight, 24% of feldspar, 14% of calcite, 6% of kaolin, 14% of quartz, 3% of ZnO, 4% of BaCO3, 25% of frit, and 5% of strontium oxide. According to the preparation method, billet material and glaze material preparation, molding, drying, biscuit firing of billet body, glazing, drying, and medium temperature glaze burning to obtain the product, wherein the biscuit firing temperature is 1120-1180 DEGC, the thermal insulation is 30 min, the medium temperature glaze burning temperature is 1100 DEGC, and the thermal insulation is 30 min. According to the present invention, with the preparation method, the product with advantages of good glaze surface quality and high glossiness is obtained so as to achieve broad application prospects.

Owner:王必胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com