Solvent-free marine antifouling coating and preparation method thereof

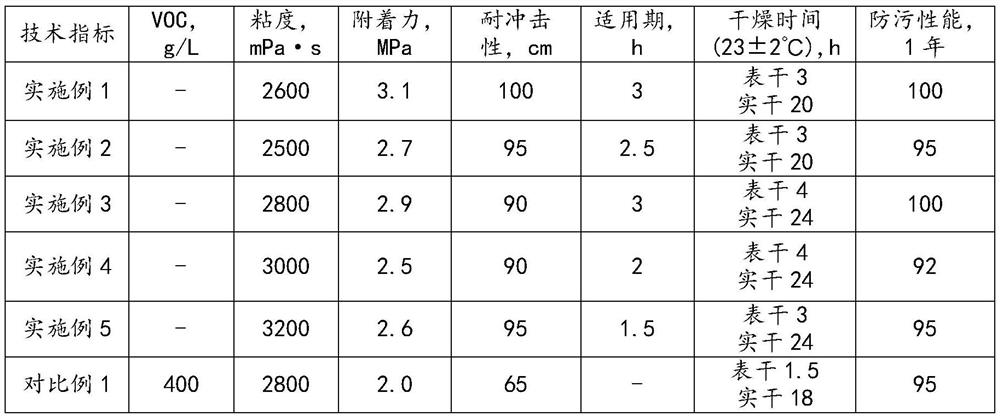

A marine anti-fouling and solvent-free technology, applied in the field of coatings, can solve problems such as polluting the environment and affecting the health of construction workers, and achieve the effects of low viscosity, excellent mechanical properties, anti-fouling properties, and good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

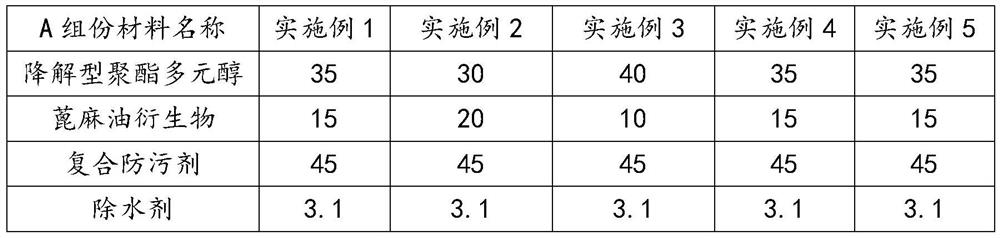

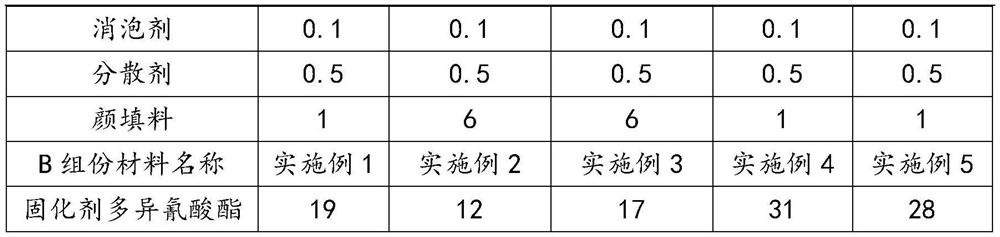

Examples

Embodiment 1

[0039] The degradable polyester polyol in Example 1 is polylactide containing terminal hydroxyl groups, the number average molecular weight is 1000, the pigment and filler are carbon black, and the composite antifouling agent is composed of electrolytic cuprous oxide, copper pyrithione and zinc oxide. The mass ratio is 35:5:5, and the curing agent polyisocyanate is hexamethylene diisocyanate (HDI);

[0040] The preparation method of embodiment 1 is:

[0041] Step 1. Put castor oil and ethylene glycol in a reaction vessel with a material ratio of 1:1.2, fill it with nitrogen, heat up to 120°C, add 0.1% tetrabutyl titanate; heat up to 210°C , after 2 hours of heat preservation, stop feeding nitrogen, and after decompression distillation removes small molecule product and water, cools and discharges and obtains castor oil derivative, and its hydroxyl value is 345mgKOHg -1 , the viscosity is 250mPa·s;

[0042] Step 2. Heat the pigment and filler carbon black at 120°C to remove wat...

Embodiment 2

[0045] The degradable polyester polyol in embodiment 2 is the polycaprolactone that contains terminal hydroxyl, and number average molecular weight is 800, and pigment and filler are iron red, and composite antifouling agent is made of zinc pyrithione, 4-bromo-2-( 4-chlorophenyl)-5-trifluoromethyl-1H-pyrrole-3-carbonitrile and zinc oxide are composed of 5:15:25 by mass ratio, and the curing agent polyisocyanate is polymethylene polyphenylisocyanate (PAPI );

[0046] The preparation method of embodiment 2 is:

[0047] Step 1, castor oil and ethylene glycol are placed in the reaction vessel with a substance ratio of 1:1.2, filled with nitrogen, and after being warmed up to 120°C, add 0.5% of the mixture of sodium methylate and triethanolamine (sodium methylate and The mass ratio of triethanolamine is 0.1:20), the temperature is raised to 220°C, and after 2 hours of heat preservation, the nitrogen gas is stopped, and after the small molecule products and water are removed by dis...

Embodiment 3

[0051] The degradable polyester polyol in Example 3 is polyethylene adipate containing terminal hydroxyl groups, the number average molecular weight is 800, the pigment and filler are composed of barium sulfate and carbon black in a mass ratio of 5:1, and the composite antifouling The agent is composed of 4,5-dichloro-2-n-octyl-3-isothiazolinone, medetomidine and zinc oxide in a mass ratio of 10:10:25, and the curing agent polyisocyanate is toluene diisocyanate (TDI) ;

[0052] The preparation method of embodiment 3 is:

[0053] Step 1. Put castor oil and ethylene glycol in a reaction vessel with a material ratio of 1:1.2, fill it with nitrogen, heat up to 120°C, add 0.04% calcium oxide; heat up to 210°C, and keep it warm for 2 hours , stop feeding nitrogen, after decompression distillation removes small molecule product and water, cools and discharges and obtains castor oil derivative, and its hydroxyl value is 345mgKOHg -1 , the viscosity is 240mPa·s;

[0054] Step 2. Hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com