Production process of aluminum sheath cable

A production process and technology of aluminum sheath, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of increasing product cost, increasing energy argon, slow production speed, etc., to achieve low production cost and a good society. Benefit and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

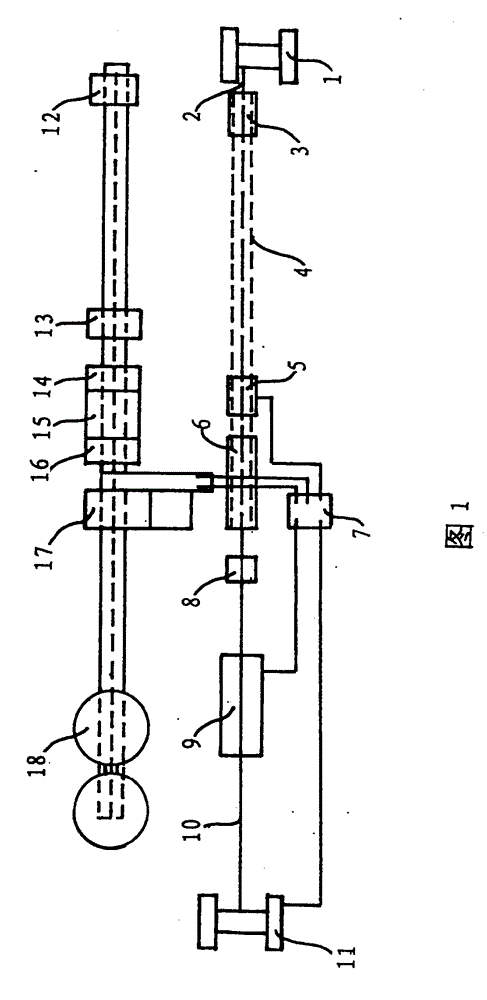

[0026] Embodiment 1 Cable diameter is 20mm, and the length is the cable of 1000 meters

[0027] The aluminum strip has a thickness of 1mm and a bandwidth of 70mm. It is formed by an aluminum sheath forming machine. The cable core penetrates into the sheath to be welded and enters a high-frequency induction welding machine. The frequency of the induction current is adjusted to 400kHz, and the welding power is adjusted to 150kw. The welding speed is 90 m / min, welding depth is 0.5mm for high-frequency welding, the welded cable is wound on the cable reel in the take-up frame after being reduced in diameter by the reducing frame.

Embodiment 2

[0028] Embodiment 2 Cable diameter is 55mm, the cable of length 1000m

[0029] The aluminum strip has a thickness of 2.5mm and a bandwidth of 190mm. It is formed by an aluminum sheath forming machine. The cable core penetrates into the sheath to be welded and enters a high-frequency induction welding machine. Adjust the induction current frequency to 500kHz and the welding power to 200kw welding speed. 80 m / min, welding depth is 2.0mm for high-frequency welding, the welded cable is wound on the cable reel in the take-up frame after being reduced in diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com