Ceramic slushing forming device

A molding device and pulping technology, which is applied in the field of ceramic processing, can solve problems such as prolonged injection time, defects in the green body, and difficulty in diverting flow, so as to save materials and time, eliminate pinholes in the green body, and realize recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

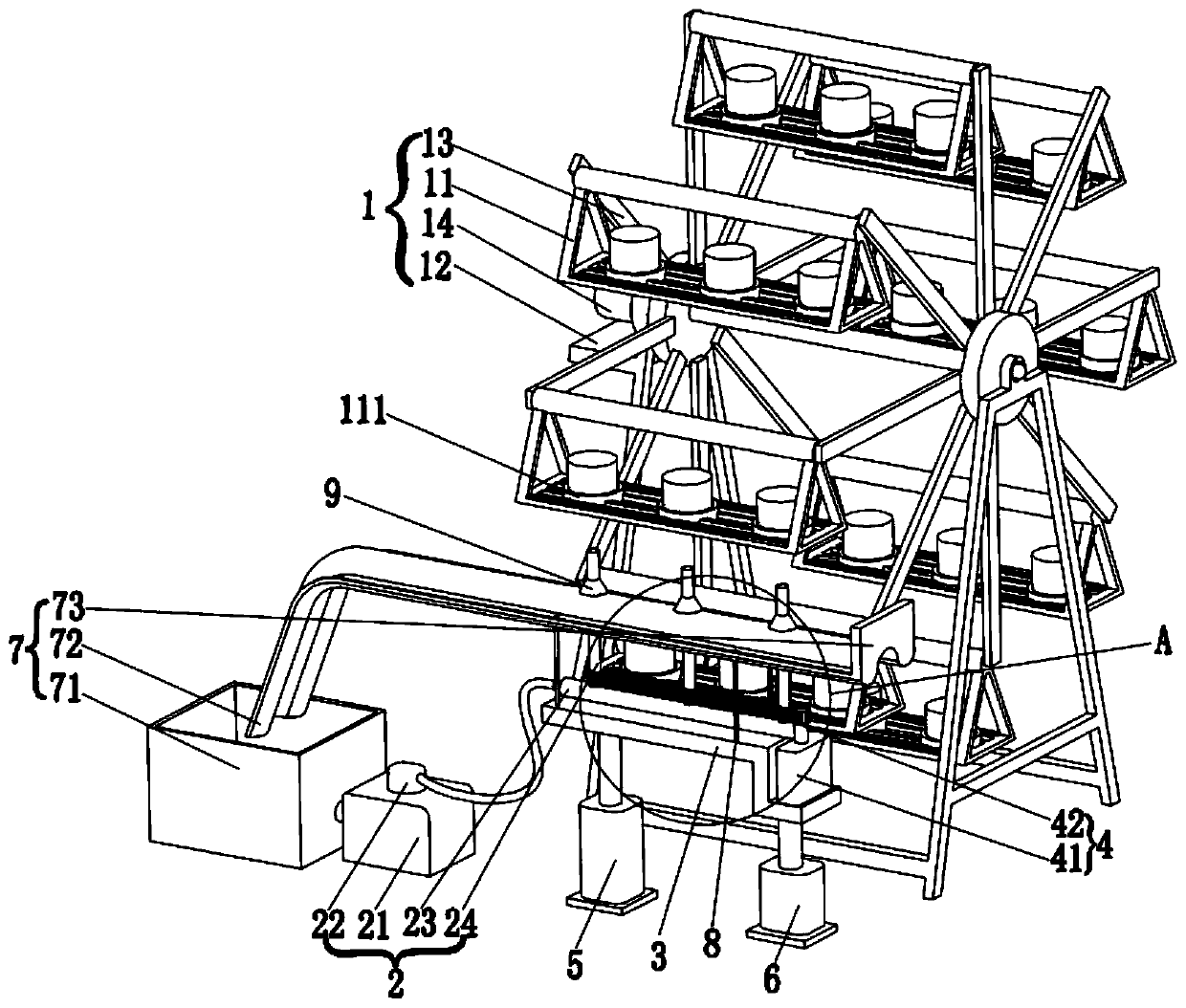

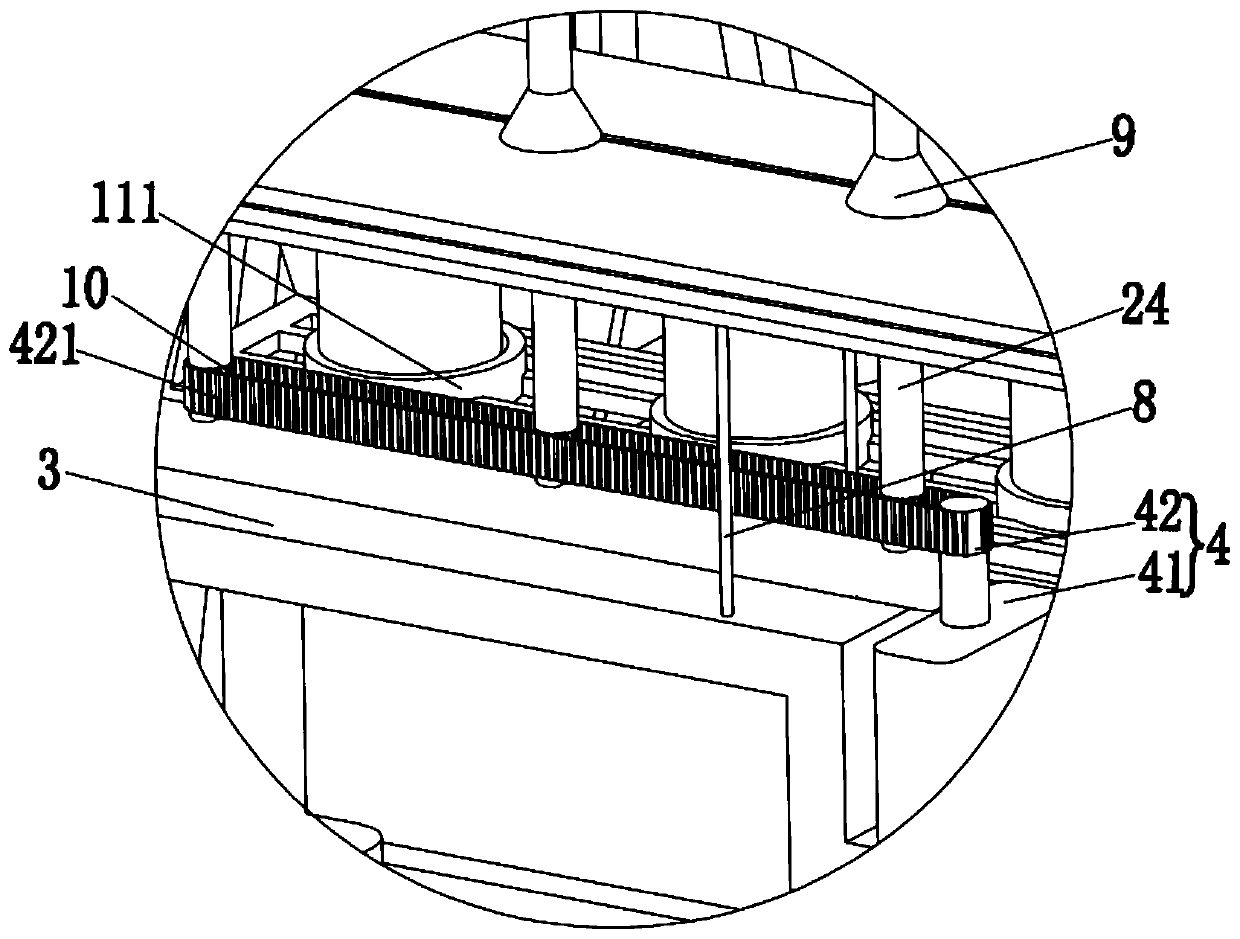

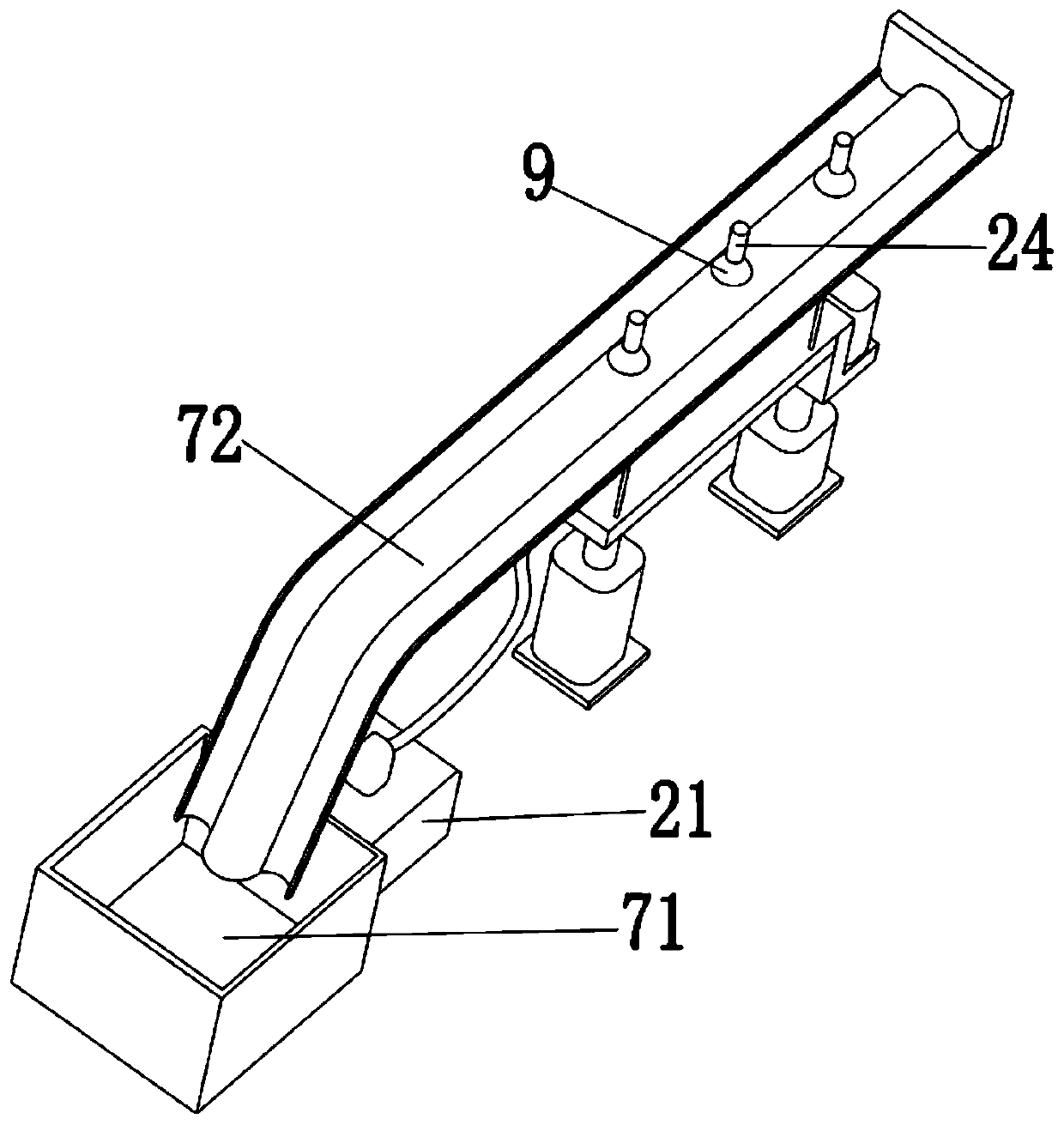

[0021] Such as figure 1 As shown, a ceramic punching device of the present invention includes a rotating device 1 of a water vehicle and a punching device 2, and the rotating device 1 is provided with a plurality of mold racks 11 for placing moulds, and a plurality of said molds The frame 11 is distributed along the circumferential direction of the rotating device 1; the punching device 2 includes a slurry storage tank 21, a punching pump 22, a slurry delivery pipe, a connecting pipe 23 and a plurality of nozzles 24, and the punching pump 22 is set In the slurry storage tank 21, one end of the slurry delivery pipe is connected to the ram pump 22, and the other end is connected to the communication pipe 23, and a plurality of nozzles 24 are arranged above the communication pipe 23, And all are rotatably connected with the communication pipe 23;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com